Archive

Pile 61 Cage Failure

A recent issue with our piling sub contractor (Skanska) has been taking up the majority of my time this week. On Friday last week whilst lifting in the top part (3 of 3) of a pile cage (Pile 61) a weld on the lifting band failed, causing three other welds to fail and the lifting band to deform. The Skanska project manager informed us that he had to stop the pile from being concreted. The lifting band is on part of the sacrificial cage that will later be removed but it there to lift and hold the cage at the right height. All good there. A good decision made on a safety and quality issue.

Pile 61 Sacrificial Cage Deformation

Pile 61: Diameter – 2.1m, Depth- 61m, with a plunge column.

Well, that is what we were initially told on Friday. As the investigatory wheels started turning it soon developed that not only had the lifting band deformed but that in ‘trying to make best of a bad situation’ they had taken the decision to cut off the top 2m of the sacrificial cage and tried to lift the cage from the bracing band 2m lower. This however also failed and deformed.

The decision to cut the top section and try again was not in the method statement and therefore not planned works (not authorised). The lifting and bracing bands are the same but the lifting bands have two welds where as the bracing bands only have one.

On investigation of the failed weld it is evident that there is only one weld (one side) instead of two sides, but more importantly that there seems to be no connection to the actual longitudinal bar. Very poor quality! Apparently the welder misread the drawing.

Weld seems not to have have had contact with band and not full width.

One of the failed welds, It should be 60mm (bar is 40mm diameter)

The proverbial grave got deeper as we found out that as of last week, although the cages are being produced still by the same fabricator (Express) the fabrication yard has moved from Neath (S Wales) to Newcastle. Neath went through a pretty serious quality assurance audit by both FLO and London Underground at the start of the contract. At no point was this communicated to us (the main contractor). Skanska have an engineer permanently based in Neath to quality check manufacture however do not have the same in Newcastle. Which has raised the question, how can Skanska provide quality assurance to us?

The result of all this is that we have issued an instruction to stop works until this has been resolved. This is at their (Skanska’s) cost which is evidently starting to hurt them (prelims alone are just over £10,000 a day). This morning I issued a communication (on behalf of the Project Manager) to the effect that following the site investigation diaphragm walling operations can continue however piling will be stopped until they (Skanska or Express) can provide the welding procedure, a witness statement from the welder, a CAT II check certificate for the temp wks re-bar cage remediation, revised H+S documentation and a joint inspection of the cages we have on site.

Regardless they will need to issue a Non Conformance Report as we have a 24 hour limitation for an open pile (i.e only supported with polymer fluid). But the pressure is currently on Skanska to prove the above. Funnily enough they aren’t too many smiles on their side of the office today.

RAT or Scaffold?

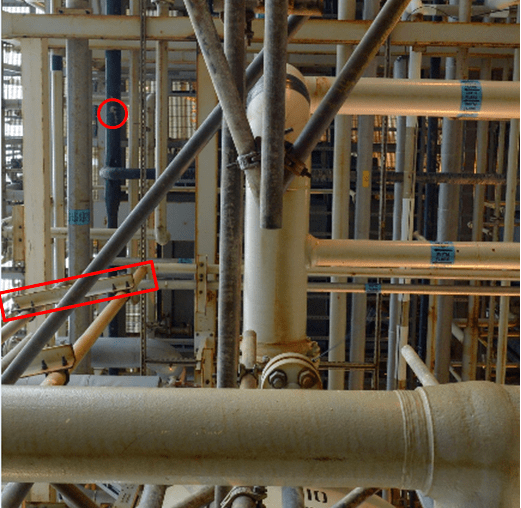

This time we’re on the BP Clair asset, West of Shetland, and the issue is access. Part of the scope of one of my projects is to install an additional 3/4″ drain line in the potable water storage system, in order to eliminate dead legs in which nasties such as legionella can lurk. Whoever designed the platform decided to put one of the drain valves 18m above the deck along one of the drainage pipe runs. The valve is circled in the below image (you’re looking straight up from the lowest deck level and the next deck up is the grating above and right of the valve).

Clair Drainage Valve Location

The new drain line will run down the support structure identified by the red oblong, with a valve at deck level so that the system drains from the deck through the grating into the sea. It’s potable water so we are ok to do that.

Getting to the valve is the problem. We can’t use a mobile access platform as such things just aren’t feasible offshore. So the answer is either a rope access team ‘RAT’ who, as the name suggests, hang off the structure on ropes to carry out the work, or build a lot of scaffolding.

The RAT are expensive due to their additional qualifications and training and there are added risks in terms of them dropping stuff and delay due to adverse weather. They are however quick and there is limited impact on platform operations or other projects.

Scaffolding greatly reduces the risk of dropped objects and construction delays but requires additional manpower and is much more time-consuming, doubling the offshore execution time. It is also very heavy and gets in the way; A few weeks ago the Clair platform stopped all non-operational work until all unnecessary scaffolding was dismantled and removed.

So what’s the answer? “Well it’s a balance between time and cost, what’s the client’s driving factor for the project?” I hear you respond. That’s exactly what I have asked the platform to decide and I’ll report back on the decison. Any views from the floor on a method of choice or similar experiences?