Anyone know about Friction?

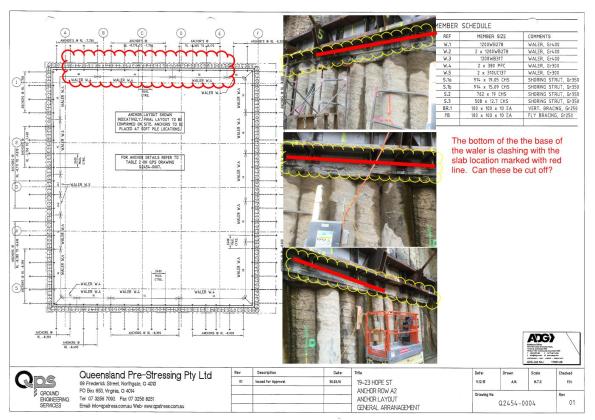

I have another problem, the bottom brackets of my walers clashes with my basement level 5 slab-exactly what we wanted to avoid. So I need to cut the brackets off before I can lay the slab. My sub contractor who designed the waler is not so happy with this idea.

My email below:

There are currently 12 bolts either side of the anchor. If we removed the four bottom bolts this would leave 8 bolts remaining.

These bolts are AS1252 M30 8.8/s with a shear capacity of 214 KN. Which would leave the bolts with a total shear capacity of 1712 KN not including the friction of steel on concrete. If I look at the anchor summary Q2454-0007 and apply the vertical shear at 45 degrees from the safe working load I get the following:

| Zone | Anchor SWL (KN) | Calculated vertical shear (KN) 45 degrees | Factor of safety |

| 3E | 1244 | 880 | 1.95 |

| 4A | 1316 | 930 | 1.84 |

| 4B | 1280 | 905 | 1.89 |

| 3D | 1160 | 820 | 2.09 |

Even if we factored the SWL by 1.5 this would still be within the capacity of the 8 bolts. Please slap me down if I am being an upstart…

I have since read a paper that indicated the coefficient of steel on dry shotcrete as 0.57, which could potentially reduce my shearing force by 467 KN. Now part of the problem I believe is that the ground anchor does not act through the ‘middle third’ of the waler and so there is a moment induced and the bolts therefore act in tension and shear reducing their capacity. How do I get around this and still cut off the brackets?

I have had a look at the UK’s Steel Bluebook and I think that with the bolts in tension the shear capacity is reduced to 80% – I am having issues looking at Australian Standards at the moment though to confirm what they use here. Any help gratefully received.

The offensive article:![Q2454-0102[A]](https://pewpetblog.com/wp-content/uploads/2016/08/q2454-0102a1.jpg?w=595)

For you Richard:

Doug, if I were you I would ignore any friction forces as there as function of the normal force and not the mass. Therefore I think they are function of the force exerted by the bolts onto the flange which you could determine using the torque settings of the bolt.

How are the bolts fixed?

If you think that the vertical force on the bolts is enough to shear them (and remember it is unlikely that they uniformly loaded due to the build tolerances and where the holes were drilled) then one option could be to leave the bottom four bolts and remove the bolts immediately above and drill a larger hole and fit larger bolts.

Gary, thank you for commenting. The ground anchors are set at 45 degrees so the force into the shotcrete (normal force) equals the vertical shear. So quite considerable. The bolts are hand tightened and don’t provide significant friction but the waler is in contact with the concrete. Imagine trying to drag steel against concrete with 80T on top. They are also Chemset into the wall. So your suggested methodology would take about a week (2 days drill, day Chemset, 2 days unbolt and cut) but importantly the bolts would be too close together in the pile leading to block failure.

Roger, I though from the picture that anchors were vertical hence the comment. Oh well, sorry I can’t help!

Mate, I hadn’t thought of doing that so it’s another way to go. The ground anchors are retaking the wall.

Gary, the walers are vertical though bud. The force in them is phenomenal.

Surely the whalers are horizontal?

They are

But the anchors are vertical

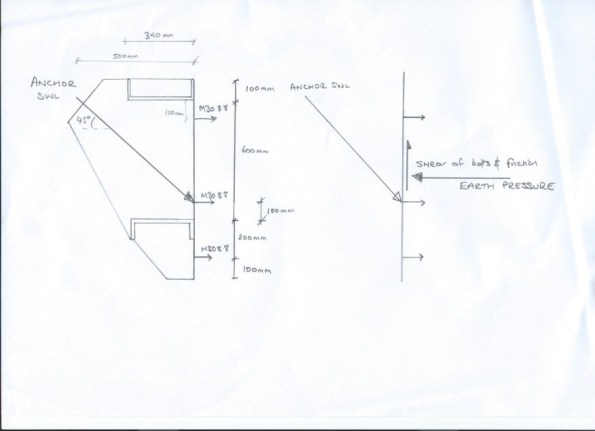

Provide a section through this to give a geometry and put some actions on it and you might have a model worth talking about. As it it stands I can’t see what you are talking about – Hoe is the shear generated? Resisting shear induced by inclined anchors? Carrying the self weight of the whaler?

Richard, there was section attached, but it seems to drop in quality when I upload it (although it seems fine on my iPad). I have attached a sketch with a model. The walers typically weigh about 3 KN/m (it is 2.4 m between anchors), on the other hand the ground anchors induce upwards of 800 KN in shear from being at a 45 degree angle, so I believe they may be the dominant action.

Ah! That makes sense now. Apologies for failure to read original correctly. I don’t think your challenge is so much the risk of vertical shear if you remove the connections and bottom channel, more the reason that bottom channel exists in the orientation that it has. The shear you could mitigate through localized propping and pockets in the slab for later infill if necessary. The question is can your whaler cope without the bottom channel? Possibly in the short term (drained) state but how long will it take for the slab to take over…

Have a go at this:

1 Draw a FBD of the bracket( there are 3D effects form the wall spanning to the bracket but see below

2 In the FBD place the anchor force as the vertical and horizontal components at the point at which the bears on

3 Allow horizontal and vertical components on the bolts

BUT ignore the steel / concrete fiction

4 Use the DPL method to assess the load on the wall and take the contributing length onto the back of the place ( your vector for earth pressure) ( see Earth Pressure Notes)

5 Now ( since you intend to remove the lower section) use the bottom wale section as the pivot and use the equations of equilibrium.

6 You have too many unknowns so use ( in the moment eqn) that the bolt loads is proportional to the distance of the bolts above the pivot point & that the shear contribution of the bolts is equal

7 Now use the interaction formula (V/Vmax)^2 + (T/Tmax)^2 <1

8 Tmax = fy A and Vmax is about fy/(root3). A ( as I recall -or use whatever the Blue Book recommends for Vmax in single shear)

I agree, I don’t think the issue is shear. I am however, only looking to remove the bolt bracket and not the PFC. The two channels function to spread the anchor load horizontally across the wall.

Their are three loads that are important in anchor installation, the lock off load, the test load and the safe working load (SWL). Now the greatest load the waters will face is the test load – this is where the anchor is stressed to 1.1 times the maximum design load to test that it will not fail. It is then reduced to the lock off load which is less than SWL. It is assumed that the anchor will strain with the deflect of the wall and induce the SWL.

So in theory the upper and lower limits are the lock off load and the test load. Now I believe that the water was designed to take the test load from the anchors and I discussed this with the sub-contractor (QPS) and the designers (ADG) on Friday and they are currently reviewing the design.

Their major concern was the combination of moment and shear on the bolt.

Regarding the drained state – I repeatedly said to the guys on site that they cannot rely on the undrained state in this condition. The site strata are very similar to COFFERDAM in that any fine grained material is thin and bounded by highly permeable coarse grained sands and gravels.

I think my fallback position to the site team has been don’t hold your breath on removing the brackets and lets plan on the worst case of having to box out the brackets that clash.

John, that last response was meant for Richard.

Ok I think I see where you are going. I will try and smash this out on Monday. We have had some change in leadership in the project and a new PM brought in so I don’t know how much latitude I will get in exploring this. The designers are due to come back to me with an answer on Monday as well.