Archive

Core wall modifications

Work has progressed significantly on site now. We have poured the basement slab, got the pre-cast walls to ground level installed, poured the internal core walls to basement level and completed the first pour of the ground floor slab. By the end of this month we should hopefully be well and truly out of the ground.

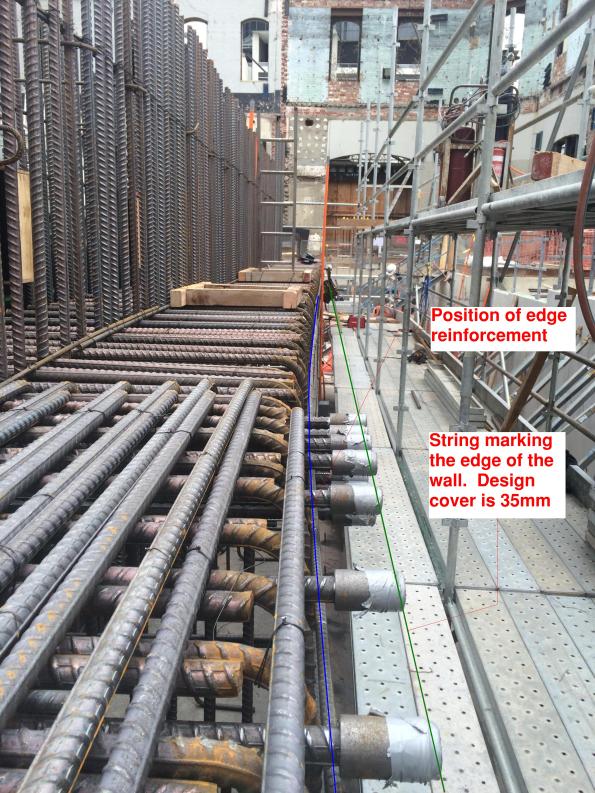

We have encountered quite a major issue on site during the last 24 hours with the external core walls. The wall was designed very close to its capacity with the strength being increased from 80MPa to 100MPa to make it work. The subcontractor responsible for the core capping beam has installed the starter bars for the walls 100-150mm out of position thereby reducing the effective depth of the wall by close to 10% as well as its capacity. This reduction in effective depth has tipped the wall over the edge and it no longer has the capacity to take the compression forces in the corner – the forces modelled are >150MN.

So what? The wall has been modelled and designed as a wall but due to the nature of the forces it must now be designed as a column which means compression ties. This will be fun when your wall currently looks like this….

Top Errors of the week No2

So we have finished digging and have started to build back up. I have moved to the Contract Admin department to focus on getting a bit of commercial experience and prep for the removal of the temporary supports.

In the last week we have finished of Basement 6 and have poured three quarters of Basement 5. The productivity has really got to some people and we have had a number of safety incidents this week. I have had to adjust this as I have just heard of another classic.

In 5th place is the site supervisor who poured 100 MPa concrete into a 50 MPa column, failed to puddle poured a 20 MPa slab, and then continued to pour a 100 MPa column on top. We now have a 20 MPa weak spot in an otherwise overly stiff column.

In 4th place is the guy who electricuted himself while drilling in a puddle. He is ok but, the site was shut down for 2 hrs.

3rd place goes to the guy who brought his own cutter on site which had some of the wires exposed resulting him getting a shock. He too is ok but, another loss of 2 hrs.

2nd place goes to the guy cutting rebar next to a spray can and the sparks caused the spray can to explode – no injuries but site shut down for two hours.

This week’s top pick though has to be the idiot who cut holes in my ground anchor walers to get his falsework in. The designers are after welding steel plate back on but, this will delay our programme. So this is now an issue. When I was inspecting the damage one of the formworkers then told me it was shocking that they hadn’t cut off more! Looks like it is time to bust some calcs.

![IMG_4577[1].jpg](https://pewpetblog.com/wp-content/uploads/2016/09/img_45771.jpg?w=595)

![IMG_4595[1].JPG](https://pewpetblog.com/wp-content/uploads/2016/09/img_45951.jpg?w=595)

![IMG_4591[1].JPG](https://pewpetblog.com/wp-content/uploads/2016/09/img_45911.jpg?w=595)