Factory Acceptance Testing

Like Stu I have recently been involved in Factory Acceptance Testing (FAT) testing but rather than spending a day on a dusty farm, I attended one at the Carrier Test Facility in Lyon, France.

The FAT visit involved witnessing the testing a variable chiller unit. It was a very useful visit as it meant revisiting the refrigeration cycle and learning more about how chillers are constructed. It also included a nice hotel and slap up meal fully paid for by the Client! Here is a picture of the Chiller being tested:

The Chiller is a 1713kW single stage chiller that uses R134A refridgerent and has a Coefficient of Performance (COP) of 4.56. As you can see from the picture, it is in fact two identical chillers bolted together and these two work in parallel and not as a two stage refrigerator. This type of chiller gives better performance at low loads as only one side will be ran. In the picture, the grey cylinders are the condensers and are basically large tube heat exchangers. The condensate is circulated through a closed loop system (45degC flow and 35degC return) that sees it either sent to the cooling towers, heating system or to the boreholes (this system is fully controlled by the building management system being designed by Honeywell). When running at full load, the system provides 2.08kW of heating. The large items on the top are the compressors and the large black insulated cylinders at the back are the evaporators and supply chilled water at 9degC flow using a 14degC return.

Of particular interest was the economiser which I admit struggling to understand fully in Phase One. So here is a picture of an economiser:

As I am sure, all of the E&Ms will remember that the economiser is used to create Sub-Cooling in order to improve COP. It works by diverting some of refrigerant leaving the condenser and then throttling it to the reduce the temperature. This colder flow of refrigerant is then used to sub-cool the main flow using a Plate Heat Exchanger (PHX).

To understand this system, I used a free to download programme called CoolPack. This program allows you to easily plot P-V and T-S diagram and conduct refrigeration calculations. I recommend this program to all E&Ms.

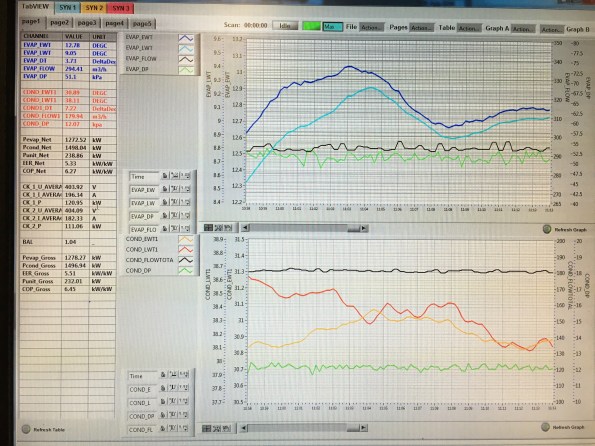

As part of the testing schedule, the chiller was ran and full, 75%, 50% and 25% load. Each time, the chiller was left for 30-45 mins to allow it to stabilise to a predetermined tolerance. Then the system was ran for a further 30mins and the temperatures and pressures were measured and plotted as shown below:

For each test to be signed off as acceptable by us, the chilled water supply and return and condensate supply and return had to be within a tolerance of the design temperatures. Also we checked the power consumption of the system, the heating and cooling outputs and COP for compliance. The Chiller passed all of these tests.

The final part of our testing schedule was to test fault conditions. To do this we increased the system pressure, simulated a loss of power and shut off the cooler pump to simulate a lack of water flow in three separate tests. For each of these tests we reviewed the chillers response such as instantly stopping, allowing the pressure to equalise across the compressor and the messages displayed on the Human Machine interface (HMI). The Chiller reacted correctly in all of the tests but during the high pressure test, one side shut down correctly and displayed the high pressure fault code but the other side shut down but displayed an electrical fault code. So we asked for the test to be ran again but for the faulty side to be ran on its own and this time it displayed the correct fault code after tripping. We also provide carrier with some requests as to how to better display messages and the visual layout of the SCADA system on the HMI.

This proved to be an excellent trip and opportunity to experience FAT testing. It also turned into a very useful refrigeration revision session!

I am hoping to do my next FAT trip to Austria next month and so look forward to a similar blog…….

Gary

Lyon – Very jealous – any particular reason for a French supplier?

No not really, it was a competitive tender and carrier are a widely used supplier and have a UK department. Plus all the test facility is ran by carrier. It is independently monitored and the only one in Europe that can test to 3MW. So chances are we would have still tested there even if we went for a UK company. Daikin, another larger chiller manufacture has their factory and testing facility in Italy.

This project is procuring a lot of plant from Europe. Our heating and cooling system is coming from Austria, all of the walls and windows are prefabed in Belgium, the generators are coming from Sweden and the ventilation is coming from Germany.

It seems that most of the major UK companies are just the UK arm of a larger international company with their factory and testing facilities abroad.

Having just queried the generator testing to answer this post, I have been asked whether or not I would like to come along. So maybe a short trip to Sweden as well………..

In addition to these Gucci trips I also visit a number of factories in the UK.

Gary, this sounds like a very important Job. The most glamorous trip I have got as a PET(C) student was a two day visit to a series of dingy northern steel fabrication/painting factories in Wigan and Leeds, all just to count some steel columns and check serial numbers. Needless to say it wasn’t much like Lyon at all.

How much does that plant Weigh? As we move closer to commencing our M&E installation programme there is a lot of confused engineers trying to figure out how we lift in some of the absurdly heavy plant kit due on site.

Tom, the chillers way 11T. I had an structural engineer check that the slab could bear the weight and it came back as just OK. The more difficult thing to work out is a suitable route to move it into place. I have been tendering the £300k package (potentially due to increase to £1.5million) to move these and some other plant I am just awaiting the decision of the Client before signing the contract. These chillers (there are 4 in total) have all been tested and delivered to a storage facility in the UK. As soon I have the plant movement contract signed I will have them delivered and get them the building ASAP. We are currently debating the method of protecting them as they will sit on site for 8-10 months before commissioning and we need to install pipework and containment a above them.

The job is reasonably high profile as it will be a global headquarters and R&D centre for AstraZeneca and MedImmune. It will be one of the world’s foremost cancer research centres and so quality is surprising high on the Clients wish list. AZ make £2.8million an hour and are so are pretty happy to sign off some additional costs to ensure quality and as a healthcare company value employees wellbeing so the client pays the project teams to go out for meals and sometimes go-karting (this Thursday). We also have lots of free lunch sessions with a bit of CPD thrown in. I don’t think many Clients would be happy with these additional costs but AZ seem to be despite our contract being 7.5% cost plus! My evening meal/wine in France cost €100 and the client was not bothered – no more £25 limits and entering it on JPA!

If you want to talk about plant movements, give me ring – I have been running with it for my site.