Archive

Contract vs Common Sense

Over the last few weeks the tunnel ventilation team have been battling the Bond Street Station (BOS) prime contractors on the captivating topic of ‘floor screed’. I think that this is a good example of working to contract rather than common sense… one of many examples on site.

The station design includes a non-structural screed finish to the plant room floors. The main items installed in these rooms are the permanent vent fans, weighing 9 tonnes each. The fans will be in situ for a design life of 25 years, and impose horizontal (thrust) and vibration loads onto the structure through floor fixings.

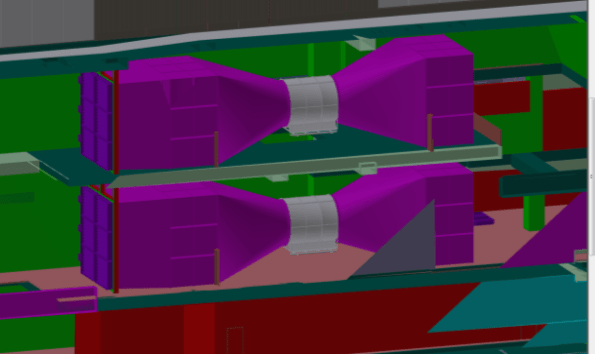

Tunnel vent fan (Horizontal Installation)

Graphic of the fan installation at Bond Street. The peach-coloured floor is currently being covered in a non-structural screed.

It doesn’t take a civil engineer to see that a non-structural screed will not stand up to this punishment for the station design life. However, despite numerous meetings pointing out the issue the station is carrying on regardless, and this week poured the screed for the plant room floor.

Image of the non-structural screed – note the lack of reinforcement. Please excuse the terrible image quality.

Why is the Bond St station working like this? A few theories:

- The contract incentives are linked to a finished room spec. It is easier to re-work than change the contract, as the commercial department works at a glacial pace.

- It is a lot of effort to search out the information on tunnel vent equipment, and involves liaison with my team. It is easier to claim ignorance, throw the screed finish in and then get money from the client (read taxpayer) to sort it out afterwards.

- The station construction is currently running with about 4 months delay; being instructed to strip-out finished work gives them a solid ‘arse covering’ excuse with the client.

The main contractors are rigidly working to the contract, and the client is unable to co-ordinate all of the separate designs and interfaces between contractors due to the sheer volume of work. I don’t think the client is innocent in all of this, they are slow at issuing instructions and slow at issuing notices to stop.

I expect they will be taking a concrete saw to the brand new floor covering in the middle of next week. Welcome to Crossrail.

Makes you wish you had volunteered for submarines!

I have just returned from an awesome week away with the family in Noosa. However, today reality has hit hard.

We have rapidly built our way out of the basement and have reached basement level 2 just underneath the props. Now that the permanent structure was in at B2 – B6, it was time to start removing the props that were used to support the basement. The culmination of nearly 3 months planning was coming to fruition.

Old aerial photo of the site (highlighted area props to be removed, North is up).

I started my checklist:

- Cylinder crush results above 25 MPa – check

- Slab over 3 days old-check

- Exclusion zones in place – check

- Construction Union on side – check

- Actions and loads – check

- Risk assessment complete – check

- Access way in place – check

- Agreement from designers – check

- Confirmation that slab is in place from the structural site engineer – check

- Risk/Issue registers reviewed – check

- Final walk around and confirmation…

SW Corner – A big hole where a slab should be

Someone hadn’t built the stairs! (North is left)

Things started to unravel pretty quickly when I discovered that the stair penetration had grown from 4 x 2.5 m to 7.8 x 10 m. I attempted to find out what capacity I had in the slab/secant pile wall/walers in order to avoid a 5 day delay but to no avail. Despite pressure from the management, I called off the demolition. This will now result in $150,000 in lost time and considerable extra work. I now need to supervise the closing of this penetration and the adjustment of the programme.

Morals of the story

- Trust but verify! If I hadn’t checked up on other people this could have gone badly wrong.

- If there is a corner to be cut, people will cut it.

- Don’t assume that just because someone has been doing a job longer than you that they know what they are doing.

- Integrity, the pressure to crack on was extreme but, if in doubt don’t.

Where I would have rather been today…

Great Sandy National Park- The sand cliffs behind were formed during the last ice age from blown sand dunes and are a great place to study slope stability of coarse grained soils. The rusty colour comes from the oxidation of the Iron in the sand (Can I claim this trip on JPA now?)