Bloody Boring

A while ago I was appointed the lead for the construction of a £1.2m borehole field for a Ground Source Heat Pump (GSHP) System. This has been a challenging task as it has meant working closely with an Austrian Sub-Contractor and numerous Sub-Sub-Contractors to design the field.

The borehole array design has taken 3 months to develop and finally sign off for construction. The final design is for an array consisting of two fields totalling 170x 200m deep boreholes arranged at 6.5m spacings. The design also includes six monitoring boreholes that will allow us to measure any heat flow between our borehole field and the two neighbouring borehole fields as it is a real risk that ours could steal heat from our neighbours and so result in financial penalties.

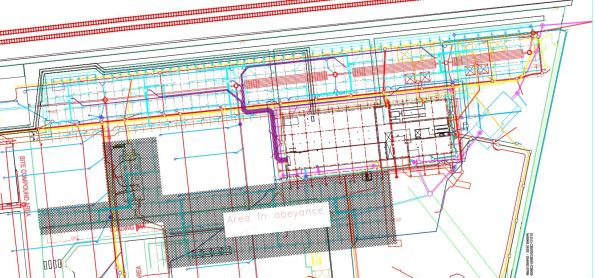

The normal recommended spacing between boreholes is 7m due to boreholes not being straight and to ensure suitable heat storage. The sub-contractor calculated that a spacing of 6.5m was acceptable in terms of heat flux density and that the boreholes would not collide at 200m. However using this figure gives very little room for error and so once placed in the borehole array lattice, the boreholes are fixed as any movement would reduce the separation below 6.5m and risk the boreholes colliding at depth. The design has proven to be a challenge and so several weeks ago I decided to split it into two smaller designs so at least a section could be approved for construction without delaying the start on site date. This has led to a two phase construction programme with the design for the second phase currently in abeyance. Here is a drawing of the finished design with the myriad of constructed and planned underground services:

The main issues for this prolonged design period has been:

- Buried Services. Generally borehole fields are constructed on virgin sites and so services aren’t an issue but due to project delays and a last minute change of sub-contractor, our borehole field is being built around existing services including drainage, attenuation tanks and HV/LV cables. Deconflicting the boreholes and services has been a real nightmare and taken up a surprising amount of my time. If I were to be involved in constructing a borehole field again I would push for the array to be constructed as early as possible and before the majority of underground services.

- Future Landscaping. We have also had to change the array design to take into account the future landscaping so that the boreholes and connecting pipework will not be damaged by tree roots or will not sit in ponds.

- Principal Designer. Since we are not the Principal Designers, all designs have to be signed off or agreed with the designers, BDP. BDP very rarely visit site and do not have a great understanding of the borehole design nor the work involved in its creation. This has resulted in designs being rejected with BDP requesting investigations to be conducted despite this work already been conducted by my team during the design development.

- Technical Submissions. The Sub-Contractor submitted datasheets for my approval and approval from BDP. Unfortunately further investigation showed that the pipes that run through the borehole were not rated to 20bar (the pressure of water at the bottom of the pipe) and the Thermal Grout (Bentonite and Silica Sand) had a thermal conductivity of 1.7W/Km2 whereas the design specified a conductivity of 1.8W/km2 and the thermal simulation was based on this figure. After rejecting the proposed materials, the sub-contractor and their supply chain conducted a number of pressure tests on the pipework and changed the grout mixing ratio.

- Contractual issues. There has been a disagreement about who is responsible for providing power and water and this has forced me to dig into the contract to resolve the conflict. the result was that I recommended that the Client should instruct the Sub-Contractor to supply a generator but that the costs should be borne by the Client due to the Client not performing his obligations under the existing contract. The Client agreed and the instruction was issued through change control. Also we stipulated that the lifting plan for some of the plant machinery had to be written by an A61 qualified Lifting AP as this is Skanska Policy. This meant that the Sub-Contractor had to pay a third-party AP to rewrite and sign the Lifting plan and the ensuing arguments have damaged our relationship with the subbie – something I am keen to resolve. So after scouring the contracts I was able to prove that this requirement was not specified as part of the tender enquiry but was first mentioned after the contract was signed and therefore can only be enforced through change control and at cost to the Client. I am awaiting approval from the Client for this change request.

Anyway, after months of redesign and compiling the mountain of paper work and permits required to get a sub-contractor on site, the sub-contractor broke ground today which is a milestone for our Project.

The Sub-Contractor has deployed two rigs to site and will construct and test two boreholes per day. We are now awaiting the arrival of the mud-cleaning equipment and grout materials before work starts in earnest next week. As well as checking and supervising the daily works, I have just initiated the design of the second borehole field and the inter-connecting horizontal pipework for the first field which is due to be constructed in four weeks.

This experience has resulted in a few lessons learnt:

- Borehole fields should be built as early as possible in a project as services are easier to move than boreholes which have a fixed separation.

- Under Management-Only contracts, the Principal Designer should be included in design meetings throughout the design process to give them greater situational awareness and to streamline the approval process. They may require some ‘motivation’ to get them to attend site meetings!

- Never assume that the materials selected by the sub-contractor are fit for purpose or suitable for the design so interrogate them.

- When writing a contract be explicit as to who is responsible for providing on-site services and ensure the Sub-Contractor acknowledges these requirements during the Pre-Start meeting. Where practical, in the scope document/contract, instruct the sub-contractor to include for the provision of their own power and water and include it as a cost item in the pricing document (BoQ/Volume 3). Then if the Main-Contractor/Client can provide mains water and power, omit this cost as a saving. If this is not possible then ensure that the cost of providing a generator (in case site power in not available) is listed on the risk register so it is still included in the cost plan.

In a few weeks I will blog about how the boreholes are constructed and tested as an interest piece and hopefully this will coincide with the Phase 1 E&Ms learning about GSHPs.

Yesterday we awarded a £1.5m package which I developed from conception and led through tendering and wrote the contract for so I will also blog about two-stage tendering and sealed-bid tenders and my experiences of them. I am trying to get the newly appointed sub-contractor on site on Monday 31 Oct 16 to start the fit out of a 132m long 4m wide services tunnel but this is tight and does not leave a lot of time for pre-start events and approving RAMS and Lifting Plans. So a busy week ahead…..