Archive

Site Update, many activities

No major problems on site but I thought that a more general site update might be due (especially in light of a potential placement for next year).

Recently in the last few weeks the activity has steadily increased as the TBM parts have been delivered on site and the SCL (spray concrete lining) team are setting up. Many robotic tracked vehicles driving around. This has all come as the primary works in the Crossover box come to an end. Construction of the box is as far as it will go until the TBMs have finished tunnelling. So there is a oncoming shift in focus of the main civils team from the Crossover Box to the Station Box. The work force on site has also ballooned 3 times what it has been for the last year.

Crossover Box

Excavation. The excavation has now been completed. All the props strain gauges are showing that they are behaving as they are expected and shape arrays in the d-walls are showing expected deflection. Now that the excavation has finished the monitoring will be reduced and shape arrays and relocated to the Station Box.

Crossover Box from B-02 level

Crossover Box from B-04 level

Soil Nailing. The last of the excavation has been possible due to the soil nailing. Over the last week BAM Nuttal has been sub contracted to install six rows of soil nails to stabilise the clay at a 70° slope. This required 24hr working to excavate 1.2m high benches into the clay at night, so that nailing could take place during the day. This is a semi-temporary condition, for up to a year. The London Clay was holding well, but for how long… no one knows squared.

6 rows of soil nails

Base Slab. A third of the base slab (pour 1 & 2) 1.5m deep, has been completed with the middle third pour (pours 3 and 4) planned for Thursday. This has gone largely without incident… surprisingly.

Steel fixing base slab pour 3 and 4.

Headwalls. The stage 1 headwalls are being cast today. They are essentially columns cast against the d-wall. These increase the stiffness of the box and provide additional load capacity to allow two 6m diameter holes to be removed via stitch drilling. The headwalls are 6.7m high and are being poured through guillotines in the formwork under pressure. This has required a lot of planning, much more than usual. It’s the first time such a high pour has been done for most on site, its going smoothly so far.

Temporary Bridge. In addition DAM structures are about to finish the erecting of a steel bridge over part of the primary structure. This will provide access across the site once the excavation has started on the station box side. The steel has just been finished. The RC deck is not being constructed (you can see some of the falsework in place at the far side.

Steel Bridge complete – RC deck under construction

Station Box

Piling and D-walling. Rotary bored piles have 5 weeks left on site which will provide quite a bit of relief as the ancillaries (casings, augers etc) for 4 sizes of piles and the polymer plant are de-mobilised.

D-wall panels are currently 39% complete. This is a delay of 4 weeks so as to reduce the impact to the FLO works, my time has been largely taken up negotiating a phased handover ahead of the completion. As expected this is highly contentious. Lots of commercial discussions but we now have a solution that should keep FLO on their programme to built target and CSL with enough room to actually complete the piles.

Capping Beam Construction. Lastly, following the handover of the first 4 gridlines (24m long) FLO have started to break down the d-walls and have started the construction of the capping beam.

First section of Station Box Capping Beam.

Semi assembled TBMs

Are all QS mental?

This isn’t directly aimed at Greg Tripp, but maybe he can help me understand why I find myself wanting to dispose of all QS at the bottom of a rotary bored concrete pile!

During piling activities a byproduct of the process is pile arisings, or spoil. In our case this is sandstone (more like builder’s sand). This needs to be removed from site and we have a sub-contractor who is paid to do this.

My first assumption was that when a tipper lorry collects spoil from site and then leaves through the gate, the ticket they leave will be used to quantify how much spoil has been removed. This will then be used to complete the valuation each month for the sub-contractor removing the spoil.

I have been asked by the QS for details on the volumes of the piles as this is actually the quantity they use to complete valuations (not what actually leaves site). I have a number of issues with this:

- What bulking factor is being used – 1m^3 of bank is not 1m^3 of loose.

- Not all material from piling is being taken off site. A large amount is used on site to improve underfoot conditions and the working areas for sub-contractors.

- Other sub-contractors also use the spoil to back-fill in their own areas (where the SES allows)

So I believe the SC is getting paid to remove spoil that is staying on site. When I discussed these issues with the junior QS, he asked me to quantify how much is being left on site – I had a look up my sleeve but was still found wanting on this figure – it’s like trying to quantify the amount of icing sugar in my cocaine.

I see the issues with paying for tickets:

- The tipper lorry may not be full

- The spoil may have come from another location or task

- Tickets get lost

But these issues can be easily controlled; the gate man can confirm the lorry is full (or 1/2 etc). Spoil on site is separated in the tasks it has come from in case of localised contamination. The gate man also keeps a register of vehicles entering and leaving site which will back up lost tickets.

I am yet to consult the QS Pocket Book, but this is my next step. I have so far given in to the QS and delivered the information they have requested.

I have another QS rant where they have specifically gone for a day-works contract over lump sum, because it was initially cheaper – again I argued against this but the QS insisted she wanted all of the risk and none of the security (facetious)…

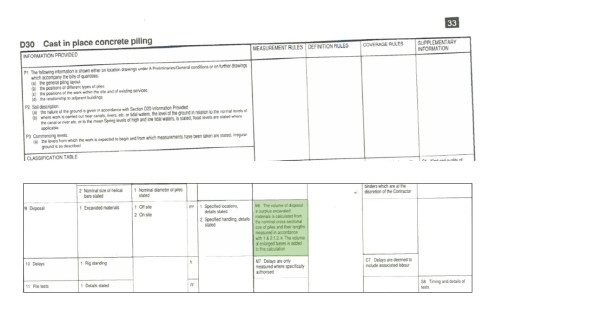

From the Standard Methods of Measurements 7th Edition, the item highlighted in green states:

The volume of disposal of surplus excavated materials is calculated from the nominal corss-sectional size of piles and their lengths measured in accordance with 1 & 2.1.2. The volume of enlarged bases is added to this calculation.

Everyday’s a school day!

Removal of props

A 700 mm CHS being removed. Note the remaining props being built over.

A few weeks ago I promised to keep you updated on how the removal of the props was going. You can see by the photo the infill around the stairs has been filled and that I followed the advice of cutting 100 mm holes in the props to de-stress them. The removal of the props occurred pretty smoothly.

The only problem I encountered was that my boss had misinterpreted a consultants advice which caused me to check the capacity of the steel left and the concrete slab. After determining that it was ok, and after the said consultant went dark and refused to answer his calls we proceeded with the demolition as planned.

Anyway all went well but a tense moment and that was a floor ago.

What the site now looks like now – We are back at ground level and currently building the transfer slab with PT concrete.

However – I am still dealing with what we have left behind. More to follow…

![IMG_5145[1].JPG](https://pewpetblog.com/wp-content/uploads/2016/10/img_51451.jpg?w=595)

In foreground a 900 mm CHS and Double 1200 WB left behind.