Archive

Poo Pipes

I learnt a few things about drainage last week.

Firstly – When Richard Farmer said that you need to plan your drainage and external levels before you build the structure, he was actually right.

Secondly – No-one in the office knows anything about designing drainage layouts other than reciting age old rules of thumb.

Thirdly – Never admit to having done a module on something unless you’re prepared for it to come your way.

Finally – Never trust Thames Water.

The problem

The new office at Chambers Wharf consists of a three storey stack of 96 cabins. The internal layout for this was practically written up on a fag packet for approvals purposes and not really looked at since. No designs were ever completed for the outside of the offices so the drainage runs, street furniture, steps and ramps, and access control now need to be shoehorned into a small gap between the office and the hoarding. Rather than working from 1 level, these features must tie in between external footpath level, internal FFL, and new office threshold level. The office must open on 31 October or 200 people will have nowhere to work.

We have also just learnt that the manhole that the site has been pumping it’s waste into for the last 2 years, and for which we have a discharge consent from Thames Water, is not, and never has been connected to the main sewer, but has been flowing back into site through an abandoned connection.

With less than a month to opening the office, everyone has just decided that they have a crucial requirement for the outside of the office (including bike racks, money gates, artist studio, and parking), and that now is a reasonable time to request it, although they don’t quite have all the details yet.

The solution

It seems impossible to keep everyone happy but turning to my trusty copy of Civil Engineering Procedure and the Joint Board of Moderators guidance (2009), it seems that I have a chance to use this to “demonstrate an ability to cope with the uncertainties of a multitude of factors making up the design brief.”

I’ve prioritised the things that we need to provide for office opening. Namely access and drainage. All of the other stuff is important but we can still occupy the office without it.

The drainage pipe had already been specified (by rule of thumb) as 150mm. Being a competent engineer I knew that using a rule of thumb was risky so I spent a morning looking into the Building Regs and speaking to the cabin manufacturers, and calculated the required pipe diameter. Turns out we need a 150mm pipe. Unfortunately there is no plan for greywater recycling. This would have greatly reduced the load on the system.

I then designed the external drainage runs (see attached pdf) and access points in accordance with the guidance in Part H, and the surrounding floor levels will be set to suit. Some compromises have had to be made. Most notable that in some areas the pipe will be laid with less than the recommended backfill, and in others it will be on the surface and boxed in. But that’s what you get for not thinking about it beforehand.

After a number of investigations, Thames Water have finally accepted that it’s their fault we’ve been draining our poo into an abandoned manhole and have agreed to make a connection, but the timescale is uncertain. In the meantime we will be installing a new manhole inside the site and if they can’t meet our timescales then we can install a macerator pump within the manhole to pump our sewage around the site to an alternative discharge point.

Now I just need to hope the showers don’t fill with poo before I go to Phase 3.

I smell gas is that your ASS again?

Just when I thought that I had heard the last of Acid Sulphate Soils (ASS) they rear their ugly head again.

Almost out of the basement must be time for Phase 3

Those of you that are familiar with my blog posts will be aware of the regular discussions I have with my brother comrades in the CFMEU Union. The latest affront seems to be that our Basement level 6 stinks! There is concern that this is a ruptured gas line. At 22 m below the surface, this would have to be a very deep gas pipe! Personally, I cannot smell gas but I thought it might be have a faint smell of ammonia.

We have checked the area with a gas sniffer and the air quality is fine. The guys are not making it up though and it really does stink down there. We still have water coming through the holes made for the ground anchors and while the quality of the piles is pretty good there is a small amount of water leaking between the secant piles. I suggested that it might be due to mould that is starting to grow on the piles and areas of stagnant water (caused by blockages in the spoon drains). This was pretty quickly shot down because if it is mould we can expect our site to be shut down. Some bright spark has hit on the idea that it is water contaminated in Acid Sulphate Soil.

Basement 6 ‘the dungeon’ – It puts the lotion in the basket

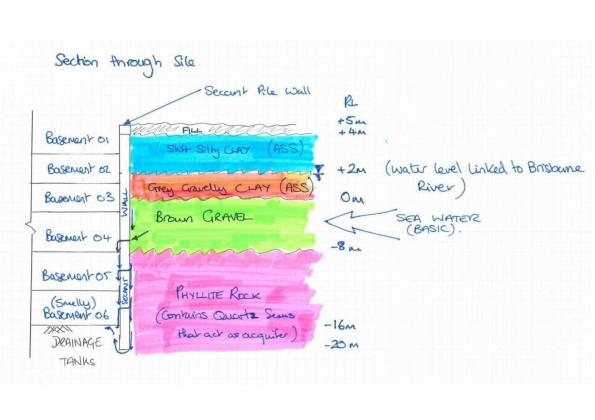

Here comes the Science again:

ASS occurs when sulphates in the soil are exposed to air and broken down by bacteria. On our site there is a clay layer that contains a high concentration of sulphates. During excavation we exposed this soil to air so it oxidised and produced Sulphuric Acid. Now we have finished excavation and all of the ASS has been removed. The only ASS around us what is left outside of our site. Now it is possible that the ground water around the site seeps through this soil and flows into our site through the anchors and from under the ground bearing slabs, where it is then collected by the site drainage system.

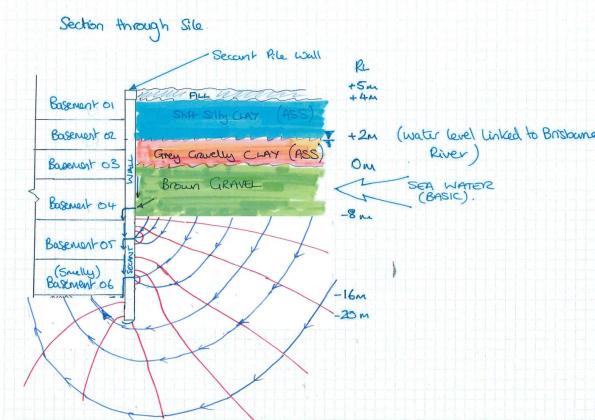

What I think is happening behind the wall (Not a flow net!)

A less than perfect flow net.

However, the soil outside of our site has not been excavated and therefore cannot have been oxidised. The site is approximately 200 m from the Brisbane River to the North and the West. As you can see from my diagram the area is flushed by sea water with the tide . Sea Water is naturally basic and so counteracts any effect of the ASS. When I last had the water tested to get approval for discharge into the stormwater drainage the water was mildly alkaline and similar to the pH of the Brisbane River. SO NO IT’S NOT MY ASS!

What are we doing about it:

I now have to hold a workshop with the blokes to explain that it is not gas or ASS in the meantime the guys are cleaning up the walls to remove any mould (although there is no mould officially there) and remove the stagnant water that is on site. We are installing some temporary fans to move the air around the basement until the permanent fans are installed.

Mechanical affecting the structural

I had a rather enlightening conversation a few weeks back and I thought it was time I finally got my act into gear to blog about it – and it is to do with lifts, or more specifically lift shafts.

Australia 108 will be 100 levels, 319m tall. This will present two significant issues with the serviceability of the lift shafts:

- Chimney stack effect. The temperature difference between the base of the building and the top of the building will be sufficient to induce an air flow up the lift shafts as the warm air at the bottom rises to the top (see Figure 1). Air is introduced at the base of the lift shaft by being sucked in though the lift doors, creating two undesired effects; firstly, the lift doors will likely jam and secondly, a loud whistling sound (often referred to as a howling). There are two fundamental options to deal with this problem. Option A) prevent air being sucked into the shaft (not feasible) or Option B) let the air do what it wants to do but provide an alternative inlet. Surprisingly Option B was the preferred option and we are looking at putting 2No 850 x 1000mm penetrations into the base of each lift shaft. Without providing additional outlets at the top of the shaft, we are not encouraging an increase in additional air flow to what naturally wants to occur.

Figure 1. Chimney stack effect

2. Piston effect. Of the 10 lifts, 9 are in banks of 3 and the goods lift is stand alone in its own lift shaft. The design speed of the goods lift is 5m/s (slower than the remainder) and is of sufficient speed to create a piston-type affect of driving air either up or down depending on the direction of the lift car. The displaced air moves around the car at a quicker speed sometimes twice that of the car (see Figure 2) creating undesirable vibration and noise. The effect is worse at the top, bottom and middle of the shaft (where the counter weights pass the car). To mitigate these issues, the cars will be made more aerodynamic and a 1000 x 2000mm penetration will be punched into the core walls at a low, middle and high level.

Figure 2. Piston effect

Prima Pearl is a 67 story building that that was completed in Jun 14 by the same management team as A108. The additional penetrations were not build into the core walls and have since had to be retro fitted to deal with the defects. Prima is 2/3 the height of A108.

Adding in air-relief penetrations seems like a good fix until you consider these penetrations were not taken into account on the initial design. In addition to these penetrations, there are also penetrations for the core crane, the hoist, two jump lifts, the jump form as well as embedded power conduit, water, waste water and sewer pipes that also, were not taken into account on the initial design. This is one core that is working extremely hard.

So what….think the design through to the finish throughout all stages of the life cycle and consult SME contractors to reduce the risk of missing critical elements of the design. This is not something I would have even thought to consider. The structural engineers are still struggling to make the core work in the serviceability state and every additional penetration makes this task that much harder.

Contract vs Common Sense

Over the last few weeks the tunnel ventilation team have been battling the Bond Street Station (BOS) prime contractors on the captivating topic of ‘floor screed’. I think that this is a good example of working to contract rather than common sense… one of many examples on site.

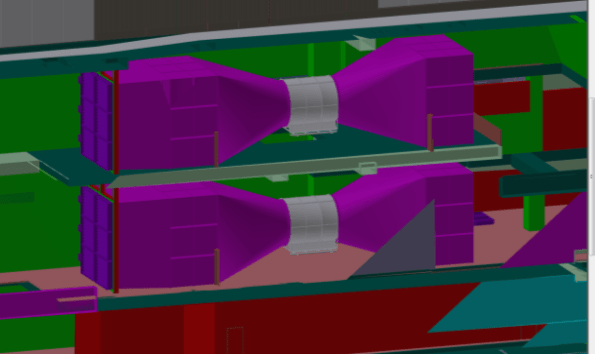

The station design includes a non-structural screed finish to the plant room floors. The main items installed in these rooms are the permanent vent fans, weighing 9 tonnes each. The fans will be in situ for a design life of 25 years, and impose horizontal (thrust) and vibration loads onto the structure through floor fixings.

Tunnel vent fan (Horizontal Installation)

Graphic of the fan installation at Bond Street. The peach-coloured floor is currently being covered in a non-structural screed.

It doesn’t take a civil engineer to see that a non-structural screed will not stand up to this punishment for the station design life. However, despite numerous meetings pointing out the issue the station is carrying on regardless, and this week poured the screed for the plant room floor.

Image of the non-structural screed – note the lack of reinforcement. Please excuse the terrible image quality.

Why is the Bond St station working like this? A few theories:

- The contract incentives are linked to a finished room spec. It is easier to re-work than change the contract, as the commercial department works at a glacial pace.

- It is a lot of effort to search out the information on tunnel vent equipment, and involves liaison with my team. It is easier to claim ignorance, throw the screed finish in and then get money from the client (read taxpayer) to sort it out afterwards.

- The station construction is currently running with about 4 months delay; being instructed to strip-out finished work gives them a solid ‘arse covering’ excuse with the client.

The main contractors are rigidly working to the contract, and the client is unable to co-ordinate all of the separate designs and interfaces between contractors due to the sheer volume of work. I don’t think the client is innocent in all of this, they are slow at issuing instructions and slow at issuing notices to stop.

I expect they will be taking a concrete saw to the brand new floor covering in the middle of next week. Welcome to Crossrail.

Makes you wish you had volunteered for submarines!

I have just returned from an awesome week away with the family in Noosa. However, today reality has hit hard.

We have rapidly built our way out of the basement and have reached basement level 2 just underneath the props. Now that the permanent structure was in at B2 – B6, it was time to start removing the props that were used to support the basement. The culmination of nearly 3 months planning was coming to fruition.

Old aerial photo of the site (highlighted area props to be removed, North is up).

I started my checklist:

- Cylinder crush results above 25 MPa – check

- Slab over 3 days old-check

- Exclusion zones in place – check

- Construction Union on side – check

- Actions and loads – check

- Risk assessment complete – check

- Access way in place – check

- Agreement from designers – check

- Confirmation that slab is in place from the structural site engineer – check

- Risk/Issue registers reviewed – check

- Final walk around and confirmation…

SW Corner – A big hole where a slab should be

Someone hadn’t built the stairs! (North is left)

Things started to unravel pretty quickly when I discovered that the stair penetration had grown from 4 x 2.5 m to 7.8 x 10 m. I attempted to find out what capacity I had in the slab/secant pile wall/walers in order to avoid a 5 day delay but to no avail. Despite pressure from the management, I called off the demolition. This will now result in $150,000 in lost time and considerable extra work. I now need to supervise the closing of this penetration and the adjustment of the programme.

Morals of the story

- Trust but verify! If I hadn’t checked up on other people this could have gone badly wrong.

- If there is a corner to be cut, people will cut it.

- Don’t assume that just because someone has been doing a job longer than you that they know what they are doing.

- Integrity, the pressure to crack on was extreme but, if in doubt don’t.

Where I would have rather been today…

Great Sandy National Park- The sand cliffs behind were formed during the last ice age from blown sand dunes and are a great place to study slope stability of coarse grained soils. The rusty colour comes from the oxidation of the Iron in the sand (Can I claim this trip on JPA now?)