Archive

This has one got me stumped

I was doing another highly exciting enviromental walk around site and surveying the latest damage to the basement. I spotted this black fluid coming out of the anchors that have been built over at Basement level 5 (RL -10 m). The anchors are drilled into medium strength phyllite rock at this level and this fluid should not be here! Note:The black fluid that you see coming down the wall is not leaking from the piles but has come from the anchors holes . The drainage pipes have not been finished yet so the water is finding its own way to the drainage tanks. So what you see running down the piles is it leaking from B5 into B6.

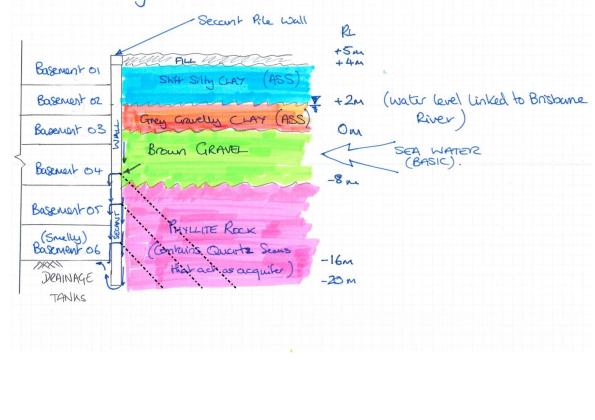

A section of the secant pile retaining wall showing anchors and ground horizons.

Some people on site thought it might be acid sulphate but the anchor is set at a 45 degree downward angle and penetrates about 14 m of phyllite rock in this area. So the toe of the anchor is at about -20 m. In addition acid sulphate water is rusty and stains concrete an orange brown colour.

I thought it might be residual oil from the drilling process that has gradually been pushed back into the basement by the seepage of ground water. I have gone back to the sub-contractors but I am confused.

Regarding the damp basement, I have recently done a study and after clearing all the spoon drains and removing the fines build up that was washed down by the hydro demolition. There are three issues that are causing the problems as I see it.

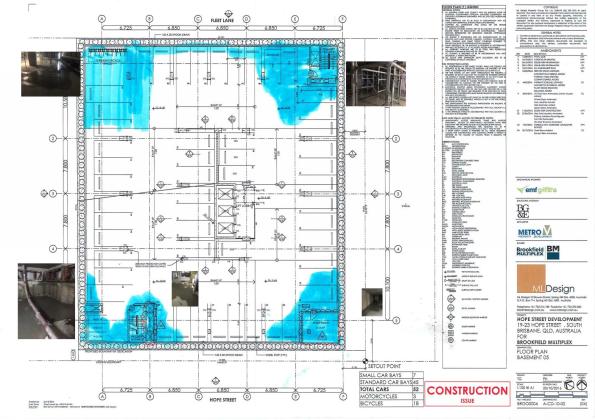

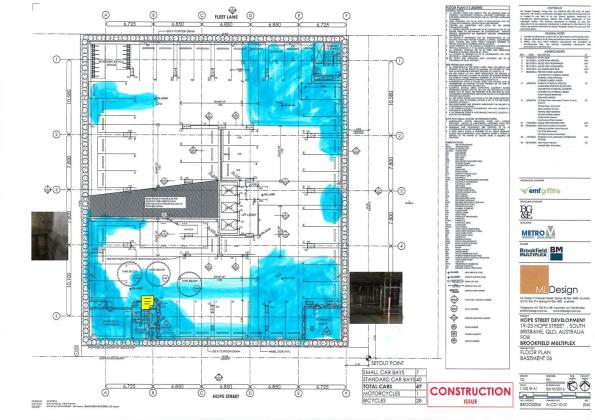

- The pumps and tanks have the capability to deal with the amount of water but are prevented from doing so because water is not properly draining into the spoon drains. The slabs currently do not slope down to the drains. This is particularly noticeable around the base of the ramps and around the hoist on B6. Water is pooling in these locations and then finding its own path down the ramps.

- Spoon drains are blocked by the plumbers using aggregate pipe because they are worried about the tanks silting up.

- Spoon drains are blocked up with silt because they haven’t been cleaned. The problem is made worse by the channels changing in depth and width along their length.

How can this be rectified?

- Multiplex construction workers to sweep clean and dispose of silt blocking drains – by the end of the week.

- The plumbers to cut the aggregate drains flush – by the end of the week.

- Once an assessment needs to be conducted to determine what needs to be ground back.

- Concreters grind back the concrete so that the drainage works.

- There needs to be a weekly maintenance set up for cleaning the spoon drains. The state of the spoon drains will be inspected during the weekly enviro inspection.

- Prior to Xmas shutdown the spoon drains need to be checked to ensure that they are clear.