Archive

Implementation of Compensation Events (CEs)

I start my Phase 3 attachment on 5/12/16 at Expedition Engineering (http://expedition.uk.com/). This is conveniently close to my current site, which will allow me to come back and investigate anything interesting, hopefully mitigating the few months I was waiting around for works to start on site. Whilst Expedition are content that they can easily provide the right experience in most of my attribute fields, they have asked me to focus on achieving experience in commercial and quality areas before I leave site, as this will be harder for them to deliver for me in Phase 3.

To achieve this before Phase 3, on the commercial side I will be working with one of the QSs to review subcontractor notified compensation events (SNCEs). On the quality side I will be managing the Inspection and Test Plan (ITP) for the tie rod installation within the cofferdam, and I have set up the temporary works inspection register for the PC and sub-contractors across all Tideway East sites. This blog will provide an update on the commercial side.

Volker Stevin (VSL), the marine subcontractor, have been sitting on a backlog of around 60 CEs (values between 1,500 and 190,000), and having boosted their QS numbers recently they are now looking to progress as many of these as possible. VSL have reportedly confessed to under quoting their works (although not deliberately), but had I not known this already it would be obvious from their CE quotations, where they have attempted to double (even triple or quadruple) bill their own labour, and S/C labour and plant across multiple CEs and their original tender.

The majority of the CEs have arisen from an Instruction to Subcontractor (ITS) or Instruction to Submit Quotation (ISQ) issued by the CVB to VSL. To speed up the process of reviewing and implementing the CEs we agreed the following process with VSL:

- CE Quotation submitted by VSL to CVB. Quotation to include:

- Excel copy of the quotation so I can add the CVB assessment

- Any relevant sub-sub-contractor quotations

- Any time/ sheets or record sheets- signed.

- Any relevant delivery tickets/ transfer notes

You may have noted that some of these are records – as VSL have allowed a backlog to accumulate then CVB are in the fortunate position of having these records available as some of the work has already happened. However, this is not usually the case with a CE quotation which is normally made in advance as a forecast. This could arguably be an unfair advantage to CVB, but CVB have allowed additional time for the quotations to be submitted, and not submitted their own assessment after the 21 day period allowed.

- One round of questioning. My comments are fed to the S/C through the QS.

- Following response to the questions hold a CE meeting to agree the terms for implementation of the CE. The quotation for the CE is then added to the project target cost, with a 50/50 pain gain.

The CE assessments are slightly complicated by the need to constantly cross reference against a CE for delayed access to site. This stems from the delayed handover due to the overrun of the enabling works PC.

The key points so far are:

- Designers can get carried away with creating the best “X” the world has ever seen, without thinking about who is paying for it. I have had to go back to designers to clarify where requests for changes came from to establish if it is additional instructed works that we are then eligible to submit a quotation for. So what – a PMI from the Client we can go back to back on the CE quotations, if it’s something that we missed in brief to the S/C then CVB foot the bill.

- VSL are more than happy to waste my time by double/treble/quadruple billing in the hope that one will make it through to implementation. So what – I have asked the QS to keep a log of the staff allocation to the CEs we are implementing so we can reduce double billing, and to compare all CEs to the back to back CE for delayed access to site.

- There is an agreed schedule of rates for staff billing, but not agreed productivity rates – so what – I can ignore the hourly rates and focus on the seniority of staff and the tasks they say they will be conducting (such as Site Agent supposedly setting out formwork and supervising the works, and the forecast of 20 hours of welding for welding tie rods to two metal plates). [Update 11/11/16 – Following my enquiry about productivity rates for staff and tasks the Senior QS has now instructed that we capture the precedents in the CEs that we are implementing to ensure that we apply them consistently. This will also help with policing the SNCEs we review and improve the consistency of VSLs QSs, as one is currently much more realistic than the other.]

- VSL want to implement the highest CE quotation possible so they have a chance at a large gain share. You might think that CVB would welcome this as we get a share too, but there is the risk that the Client will implement a lower sum and CVB could have to foot the difference.

- We need to come up with a policy for accounting for overheads for items not required on site, but for which the sub sub contractor will still be paying for as a result of the CE. For example – the fencing gang is on site longer as a result of a CE, they have a van which is not allowed on site due to the Works Information, but they are still paying hire charges on the van and would be using it if they were not still on site as a result of the CE. We’re still working on this one and are keen to get it right as it will set a precedent for some significant amounts in some of the CEs. Any suggestions?

The next blog will cover the quality and temporary works elements.

(Update

Steel Penetrations

The New Perth Stadium faces a race to be ready for the first Australian test match of next summer – which also happens to be an Ashes year. I’m hoping I’ve contributed enough to badger a couple of hospitality tickets for the first day for some good old fashioned international relations engagement.

Throughout Phase 2 I have managed the entire services steel penetrations register and works. This involved receiving penetration requests from sub-contractors’ BIM modellers, confirming all alternative solutions have been exhausted, gaining structure approval and instructing a cutting firm to carry out the works. In the 7 months I have spent on site, over 200 penetrations have been cut in the structural steel. As the majority of these works have been completed on ‘day rates’ Multiplex is now feeling the cost of hurried structural design, which was forced through without considering the full extent of services within a stadium.

After a conversation with the Senior Services Manager, he claimed every effort was made to delay the steel frame construction so that most (if not all) service penetrations could be captured. Instead, the button was pressed acknowledging future penetrations would be required. Although not privy to exact costs, I assume the price of cutting hundreds of penetrations (and installing stiffeners) in structural steel far outweighs the cost of delaying steel fabrication over two years ago. Something for us all to consider in the future..?

Just for a bit of fun:

…?

…?

This has one got me stumped

I was doing another highly exciting enviromental walk around site and surveying the latest damage to the basement. I spotted this black fluid coming out of the anchors that have been built over at Basement level 5 (RL -10 m). The anchors are drilled into medium strength phyllite rock at this level and this fluid should not be here! Note:The black fluid that you see coming down the wall is not leaking from the piles but has come from the anchors holes . The drainage pipes have not been finished yet so the water is finding its own way to the drainage tanks. So what you see running down the piles is it leaking from B5 into B6.

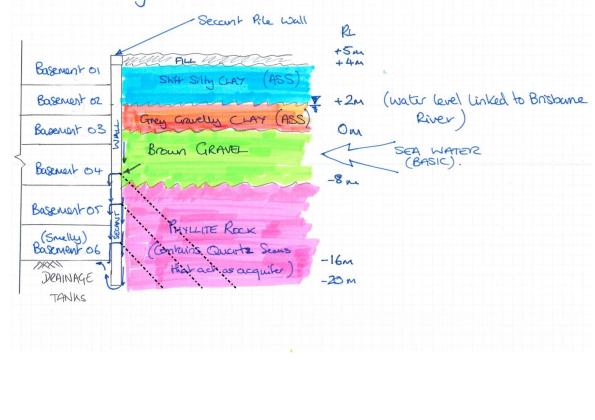

A section of the secant pile retaining wall showing anchors and ground horizons.

Some people on site thought it might be acid sulphate but the anchor is set at a 45 degree downward angle and penetrates about 14 m of phyllite rock in this area. So the toe of the anchor is at about -20 m. In addition acid sulphate water is rusty and stains concrete an orange brown colour.

I thought it might be residual oil from the drilling process that has gradually been pushed back into the basement by the seepage of ground water. I have gone back to the sub-contractors but I am confused.

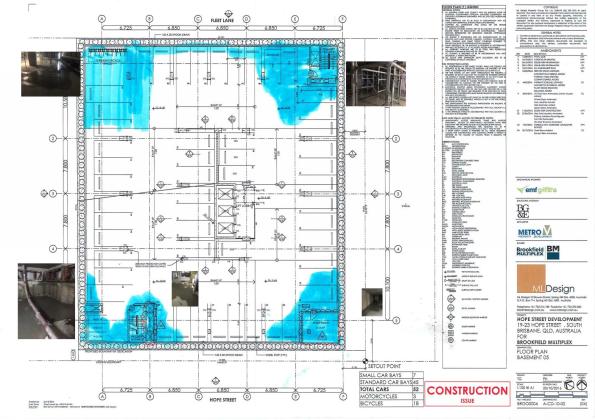

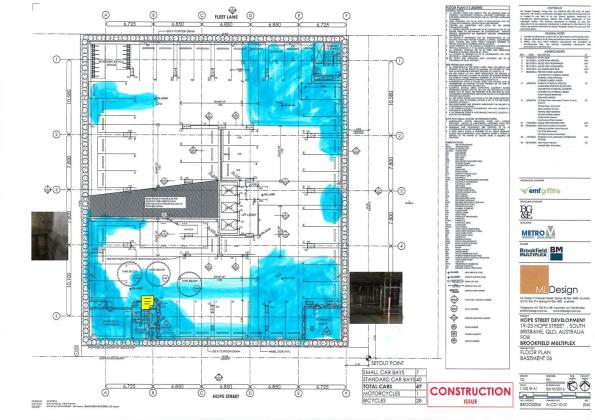

Regarding the damp basement, I have recently done a study and after clearing all the spoon drains and removing the fines build up that was washed down by the hydro demolition. There are three issues that are causing the problems as I see it.

- The pumps and tanks have the capability to deal with the amount of water but are prevented from doing so because water is not properly draining into the spoon drains. The slabs currently do not slope down to the drains. This is particularly noticeable around the base of the ramps and around the hoist on B6. Water is pooling in these locations and then finding its own path down the ramps.

- Spoon drains are blocked by the plumbers using aggregate pipe because they are worried about the tanks silting up.

- Spoon drains are blocked up with silt because they haven’t been cleaned. The problem is made worse by the channels changing in depth and width along their length.

How can this be rectified?

- Multiplex construction workers to sweep clean and dispose of silt blocking drains – by the end of the week.

- The plumbers to cut the aggregate drains flush – by the end of the week.

- Once an assessment needs to be conducted to determine what needs to be ground back.

- Concreters grind back the concrete so that the drainage works.

- There needs to be a weekly maintenance set up for cleaning the spoon drains. The state of the spoon drains will be inspected during the weekly enviro inspection.

- Prior to Xmas shutdown the spoon drains need to be checked to ensure that they are clear.

Duo – Central Park; key achievements…

Here are the key achievements of the Duo – Central Park project during my attachment so far. It hopefully provides Phase 1 students with an insight into the works packages Phase 2 can expose you to, when dealing with early structural works.

Feb – Apr 16. Although Multiplex had won the tender, several months past before a head contract was agreed. Site establishment and ‘early works’ commenced under a pre-contract budget. With the bulk excavation complete, the pre-contract budget allowed detailed excavation of footings to commence and the completion of general site establishment including temp services. In the meantime, project staff engaged in value engineering, rationalising, reviewing drawings and the identification of method statements based on anticipated buildability issues.

May – Jun 16. Contract signed. Detailed excavation continued and two tower cranes were installed. Whilst the majority of the project progressed through the pouring of footings, columns and SOG, my focus was on temp works in and around a heritage building. These temp works were required to provide structural stability to the heritage building before work on the new, adjacent structure could begin. These works involved underpinning and structural steel supports. I also had to identify methodologies for these key areas.

Jul 16. With the heritage building structural works complete, we progressed with piling and pile cap excavation.

Aug – Sep 16. With the piling out of the way, works in my AOR have progressed with the construction of four pile caps, a lift pit, PT slab removal and in-ground services.

Oct – Nov 16. My final couple of months have seen the completion of the following works in my AOR; SOG, columns from Basement to L1, a lift shaft and two suspended slabs. I have also completed the removal of HAZMAT (asbestos and lead dust) from the heritage building.

Early structural works provide exposure to a wide range of works packages. The individual can gain experience in ground investigation, piling, mass concrete, reinforced concrete, prestressed concrete, structural steel and more. The site experience goes beyond these packages to include high risk workshops, method statements, contract admin and stakeholder management to name but a few. In my experience, being a site engineer is like being a Tp Comd. I view my PM as my OC, my site manager as my SSM, my project engineer as my BGE / OpsO, my senior site supervisor as my staff sergeant, junior site supervisors as section commanders and the subcontractors as soldiers. To quote Gus, the only difference is ‘soldiers follow orders and require far less supervision’. Finally, for anyone thinking of working on a structure for their Phase 2 attachment, I think the course prepares you extremely well but I would have benefited from being more efficient at reading structural drawings. I have sent a drawing exercise to John Moran, not a bad place to start. Oh, and if you can, avoid scheduling reo like the plague!