Background. Since February 2016, I have been employed by Multiplex on the Brisbane Casino Towers (BCT) project, in South Brisbane. I left the BCT site on 28 November 2016 and started my Phase 3 attachment, at Multiplex Head Office, Queensland, Australia. I am currently employed in the design team working to the only chartered engineer in Multiplex Queensland. I won’t cover specific technical issues as Andy B has already done an excellent article on his beam design.

Experience so far. After completing the preparation for the removal of the retaining wall restraints at BCT, I moved to the Head Office Engineering Design Team. Since I have arrived I have mostly been providing project support to the Jewel project on the Gold Coast and my old site BCT but, I have done preliminary work for the New Business Team.

Roles and responsibilities. I am involved in providing technical advice to three areas of the business.

- Project support. Core business of the design team is to provide assistance in resolving issues with the projects’ design consultants. The design team provide oversight capability to designers ensuring quality is maintained, designed to fit for purpose, are constructible and cost-effective. The early identification of design risks, is critical to maintaining the projects’ programmes.

- New business. The design team has considerable day-to-day contact with the new business team. They technically review all designs prior to tenders being submitted. They provide oversight on design consultants’ rates, comment technically on sub- contractors’ initial bids and conduct preliminary assessment on the suitability of designs. Risk identification is an essential part of this task. Alerting the new business team to potential hazards early on in the tender process allows risks to be suitably managed. Recently they have had significant involvement in the geotechnical assessment of future projects.

- Novel technology. Multiplex employee a group of academic engineers to come up with novel solutions to engineering problems. However, they are not often best placed to understand the limitations of the project. The role of the design team is therefore to interpret the requirements of the site and project teams and brief the academics accordingly.

Stakeholders. Given that the Design team are often called in when an issue has been identified.

- New Business Team. Supportive and routine relationship.

- Consultants. Cautious and sometime hostile.

- Project Teams. Supportive but cautious of exposing their own errors to head office.

- Sub-contractors. Neutral to hostile compared to the details of the issue.

- Clients. Generally cautious between neutral and hostile.

Current Projects. There are several ongoing projects but I will concentrate on the ones I am working on now.

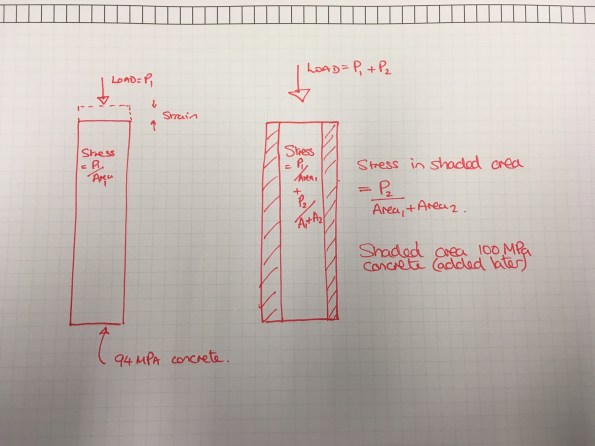

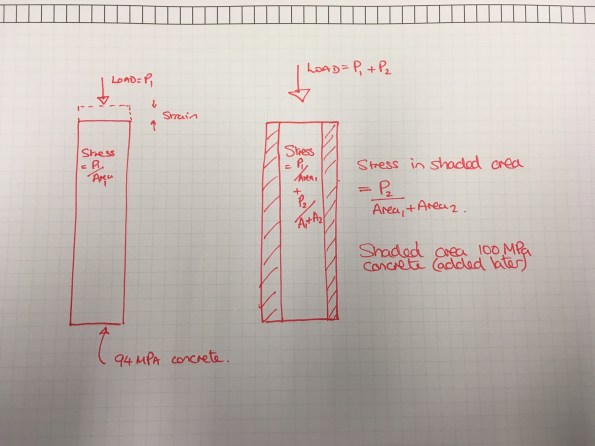

BCT continues to have issues – What happens when a basement column fails to achieve strength (100 MPa)

Brisbane Casino Towers (BCT). ($108M) My old site continues to be an utter disaster. The latest debacle is that the concrete strength is failing to come up to strength so remedial works are going to hare to be made to the basement columns. The Johnny age 5 sketch was an attempt to show why you have to allow for the current strain when determining the extra amount of concrete to add around a column that has not reached strength. Long story short the stress from the half built structure is already in the 94 MPa column and any additional load is shared between the existing column and the extra concrete. An interesting couple of days on this one – pouring through Australian Standards and contracts. BLUF – the concrete supplier has been very naughty and needs to fix this and compensate Multiplex for time lost – @ $35,000 a day – very expensive!

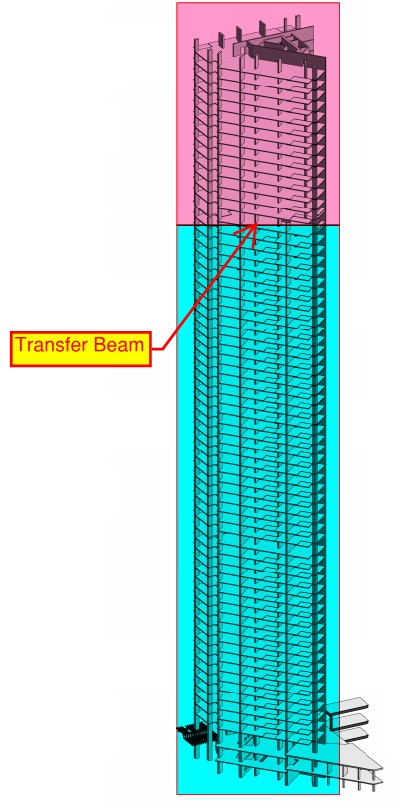

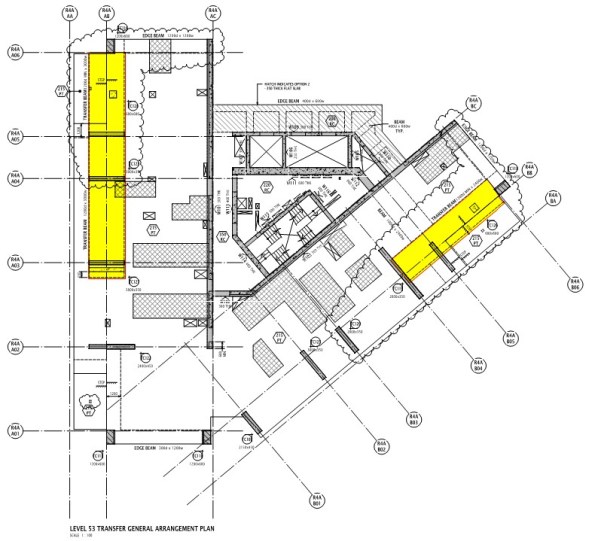

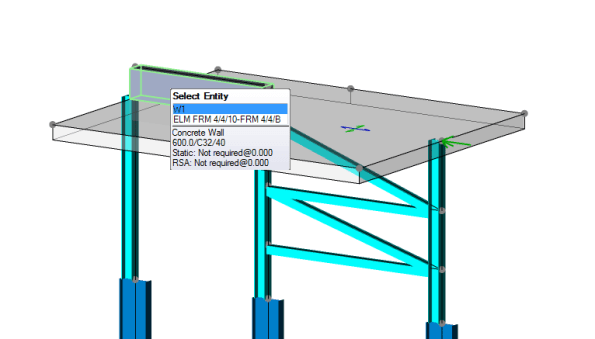

Jewel. ($600M) The Jewel will be Australia’s largest beachfront mixed-use development and the first absolute beach front development on the Gold Coast in more than 30 years.

The luxury development is located on Old Burleigh Road in Broadbeach, the three-tower development will include a three-level podium, a six-star hotel comprising 171 suites and 512 one, two and three-bedroom luxury apartments and premium residences. The development will feature three levels of basement parking to accommodate 816 cars.

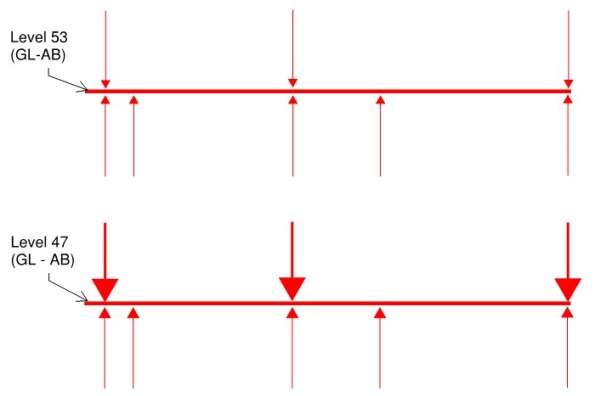

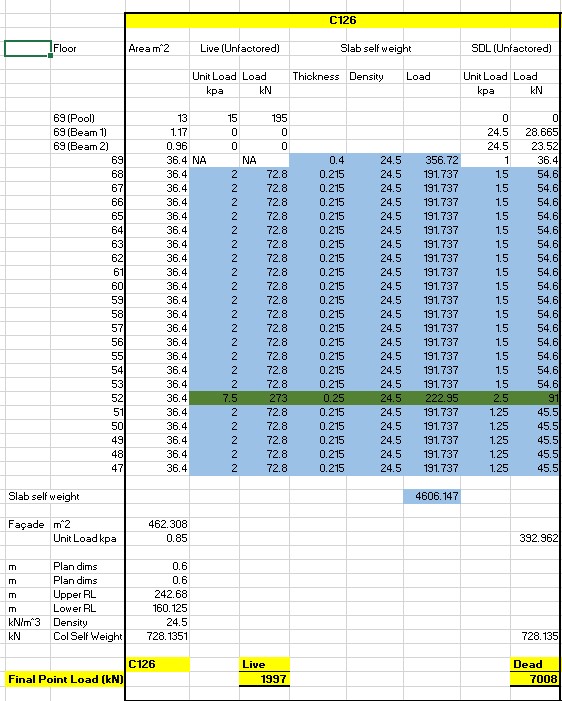

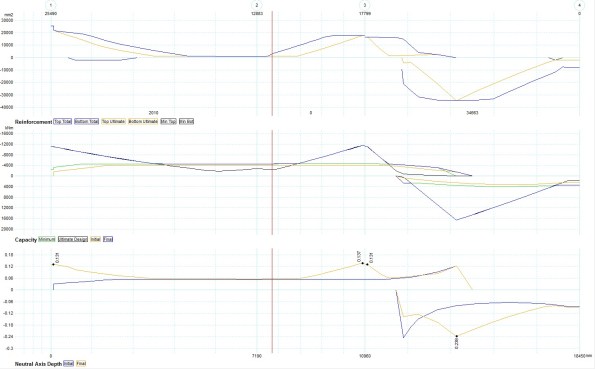

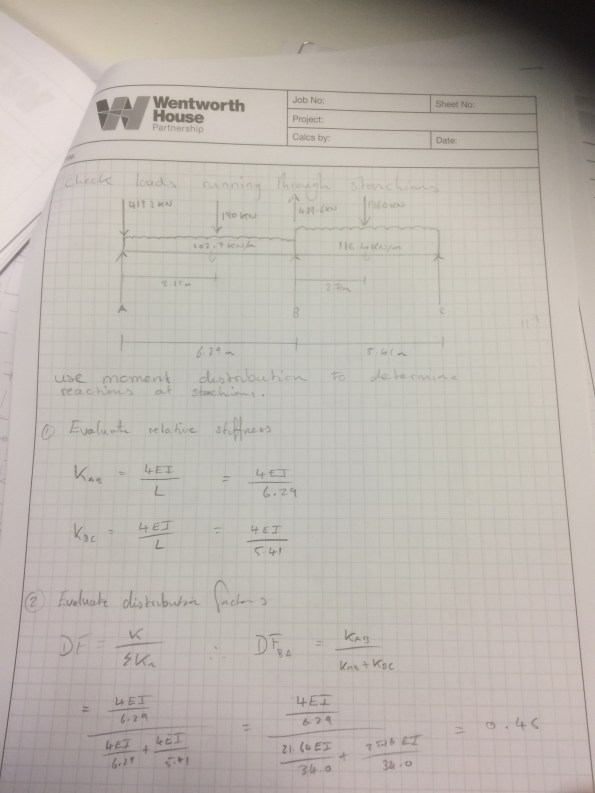

Problem 1. I have been conducting a value management exercise on the design of the slabs. I have cut the reinforcement by a third at Podium Level 2. I have cut several slab thicknesses down by 25%. I am planning to do a TMR on this value management exercise and why consultants over engineer designs! (more to follow).

Problem 2. The Towers are connected by steel foot bridges which presents a problem during wind loading and earthquakes. The footbridges need to be able to accept deflections of up to 850 mm because the towers will move independently. Currently ther is only an expansion gap of 50 mm so this needs addressing. Additionally, the last slab level to connect the towers (ground) becomes a tension member during an earthquake and this needs to be allowed for with extra reinforcement so I need to conduct some checks to ensure this is done.

Future Business. Key new Business that we are looking to win.

Queen’s Wharf. ($1B+) Queen’s Wharf Brisbane has the capacity to realise Brisbane’s growth and profile aspirations by delivering a truly-place defining precinct with significant transformational impacts on Queensland’s economy, jobs, tourism, visitation, liveability and image.

The Destination Brisbane Consortium vision for Queen’s Wharf Brisbane is to design, build and manage with excellence a place for which Brisbane will be renowned and its people immensely proud.

The Destination Brisbane Consortium will deliver an iconic redevelopment at the city’s heart that invigorates the entire precinct and delivers striking landmark architecture as part of the best integrated resort in Australia.

Destination Brisbane Consortium’s development of the Queen’s Wharf Brisbane precinct will deliver transformational impacts on the Queensland economy through job creation, training and tourism.

The Development of Queen’s Wharf Brisbane will include the following key features:

- The iconic signature “Arc” building

- A spectacular Sky Deck, giving stunning views of the Brisbane River and skyline, complete with restaurants and bars

- The repurposing of existing (Treasury casino and Hotel) heritage buildings to maximize their contribution to Brisbane

- Five premium hotel brands, including the world renowned Ritz-Carlton and Rosewood brands plus the introduction of Brisbane’s first six star hotel

- Infinity resort pool overlooking the Brisbane River and Southbank

- Fifty restaurants and bars, from hatted fine dining to pop-up cafes

- Moonlight roof top cinema, black tie event space and a variety of outdoor lifestyle opportunities

- Cohesive Bridge-to-Bridge precinct, integrating heritage and new architecture

- 12 football fields of public event space.

Stockland Toowong. ($200M) Three 25 storey residential towers located at 23-79 High Street Toowong, on a 1.3 hectare site, currently the site of a Woolworths supermarket. Interestingly from a geotechnical point of view the area is situated in very low to very high strength phyllite and alluvium deposits. The basement will be below the water table and due to the proximity of other buildings there will not be any underslab drainage so there is significant hydrostatic uplift on the ground bearing slab. The basement is going to be a nightmare to build. I am the technical lead for this project – so no doubt more to follow. Stages. The project will be split into three stages. With sales from the first stage being essential to provide funding for the others.

Stockland Toowong. ($200M) Three 25 storey residential towers located at 23-79 High Street Toowong, on a 1.3 hectare site, currently the site of a Woolworths supermarket. Interestingly from a geotechnical point of view the area is situated in very low to very high strength phyllite and alluvium deposits. The basement will be below the water table and due to the proximity of other buildings there will not be any underslab drainage so there is significant hydrostatic uplift on the ground bearing slab. The basement is going to be a nightmare to build. I am the technical lead for this project – so no doubt more to follow. Stages. The project will be split into three stages. With sales from the first stage being essential to provide funding for the others.

- Stage 1: 25 storey residential tower (184 units), with ground level retail uses (1,354m2 GFA) and an expansive plaza, and associated parking and servicing. This has a 3 storey car park basement.

- Stage 2: 25 storey residential tower (172 units) fronting High Street, ground level retail uses (328m2 GFA), expansive podium private open space plaza and associated parking.

- Stage 3: 25 storey residential tower (174 units) fronting High Street, ground level retail uses (267m2 GFA), expansive podium private open space plaza and associated parking.

Stockland Toowong. ($200M) Three 25 storey residential towers located at 23-79 High Street Toowong, on a 1.3 hectare site, currently the site of a Woolworths supermarket. Interestingly from a geotechnical point of view the area is situated in very low to very high strength phyllite and alluvium deposits. The basement will be below the water table and due to the proximity of other buildings there will not be any underslab drainage so there is significant hydrostatic uplift on the ground bearing slab. The basement is going to be a nightmare to build. I am the technical lead for this project – so no doubt more to follow. Stages. The project will be split into three stages. With sales from the first stage being essential to provide funding for the others.

Stockland Toowong. ($200M) Three 25 storey residential towers located at 23-79 High Street Toowong, on a 1.3 hectare site, currently the site of a Woolworths supermarket. Interestingly from a geotechnical point of view the area is situated in very low to very high strength phyllite and alluvium deposits. The basement will be below the water table and due to the proximity of other buildings there will not be any underslab drainage so there is significant hydrostatic uplift on the ground bearing slab. The basement is going to be a nightmare to build. I am the technical lead for this project – so no doubt more to follow. Stages. The project will be split into three stages. With sales from the first stage being essential to provide funding for the others.