Sustainable Engineering and Midnight Lux Levels

Happy new year to all! An update from Gatwick…

Sustainable Engineering

In order to bolster my E3 UK Spec competency of proving sustainable engineering, I’ve managed to get involved with the in-house Environment and Sustainability team. I’ve now got responsibility for an embodied carbon survey to be conducted on the newly finished Pier 1 (see http://www.dailymail.co.uk/travel/travel_news/article-3640991/Gatwick-unveils-186m-state-art-terminal-link-fascinating-time-lapse-video-showing-construction-hi-tech-new-baggage-system.html for a rather good time lapse video – particularly of the baggage system!).

The survey is aimed at quantifying the amount of carbon emitted to atmosphere during the manufacture, transport and construction of the building and it’s materials per m2. This will give a measured baseline of Gatwick’s current sustainable construction performance and try to fill the void between strategic aims of ‘constructing more sustainably’ and the on the ground reality of how well projects are delivering to this.

Broadly, materials such as steel tend to have much higher embodied carbon due to energy intensive manufacturing process. Materials such as timber have much lower embodied carbon as less energy is required to produce it.

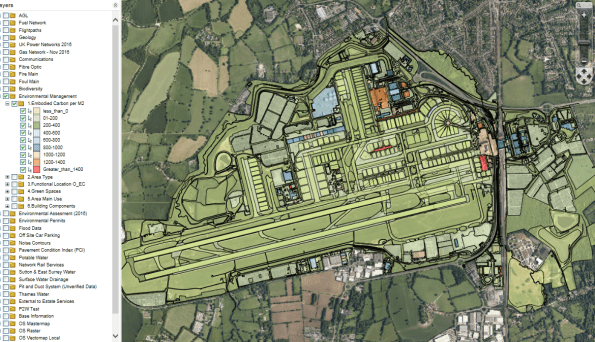

The aerial shot below gives an overview of the existing understanding of the Gatwick site’s embodied Carbon, which is currently quite rudimentary and not much more than a wet finger estimate. Green indicates low embodied Carbon, red indicates high. Pier 1 is the red block to the right hand side of the site view.

Once the detailed Pier 1 survey is complete, I aim to suggest suitable recommendations into Gatwick construction material standards to reduce embodied carbon where possible.

Night time lighting testing.

The first project of the baggage programme is now in the testing and commissioning phase (see progress photo below). For my electrical package, this involved dead and live testing of final circuits, testing of the lighting controls and testing that the specified lighting lux levels have been met.

Emergency lighting testing must be conducted outside of working hours to allow the bag hall regular lighting to be switched off, thus I joined the contractor to conduct the lighting and emergency lighting test in a window between 2330hrs and 0230hrs with lux meter in hand to conduct the tests. In the photo below (yes, that is my hairy arm) we are testing that the electrical distribution board receives the minimum of 300lux on vertical plane under normal lighting conditions prior to testing that it meets 15 lux under emergency lighting conditions (and after 3hrs drain of the battery).

Stu, what standard of grams of carbon per m2 square are you trying to achieve and what is driving this standard? Planning requirement? BREEAM? If BREEAM are you also checking the Lux per Watt values of the lighting?

To be honest Gary, I think Gatwick is not at that stage yet – part of the point of the survey is to establish what is a feasible embodied carbon target. At the moment they have no idea other than a desire to reduce embodied carbon; it arose mainly as it was good PR for the second runway bid.

On the lighting side minimum LED efficiency is 90lm/W from GAL standards. There is a whole raft of minimum criteria to be met for new lighting installations from colour, efficiency, operating temperatures, maintenance schemes, rendering index. Contractors are generally steered towards preferred luminaire suppliers to ensure that the standards are met – in this case Dextra.