Archive

Phase 3 – Week 1

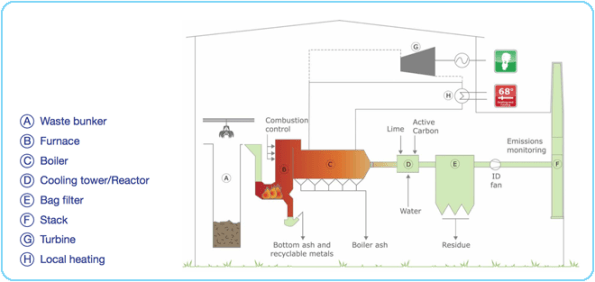

At the start of this week I began my Phase 3 attachment with Ramboll in Birmingham. I am working in the Buildings department, currently tasked with an Energy from Waste (EfW) plant in Gloucestershire, this is a power plant that burns non-recyclable waste to produce power (E&Ms can tell you more).

The EfW plant is basically a series of huge steel structures with smaller concrete structures inside them. The loads from the mechanical plant in here pose the biggest issues to the designers, as well as another engineers designing the mechanical systems, they are also responsible for the steel work that supports this. Ramboll are essentially responsible for the housing structure and foundations.

In my first week I have been tasked with looking at the Boiler hall structure. An RC box that houses the turbines and boilers (big loads). The client initially issued loads on the agreement they would not increase by more than 10%. These have now more than doubled and I needed to assess whether the beams and columns were still sufficient at current sizes (increase in steel was presumed).

The critical beam was already 2m deep spanning 13.58m and the column this sits on is 14.75m tall (750mmx750mm). After my week of assessments (by hand) the beam has increased to 2.5m deep and the column is just about suitable. I have also now designed a new roof slab which sits on top of the Boiler hall with some water tanks and other loads.

I think I have just about got through the other engineers watching me struggle with hand calcs and lots of rubbing out, whilst everyone else bashes away at their computers. I will add some photos from the computer model when I have worked out how to Print Screen!

Site Inspection – in at the 1.4m deep end…

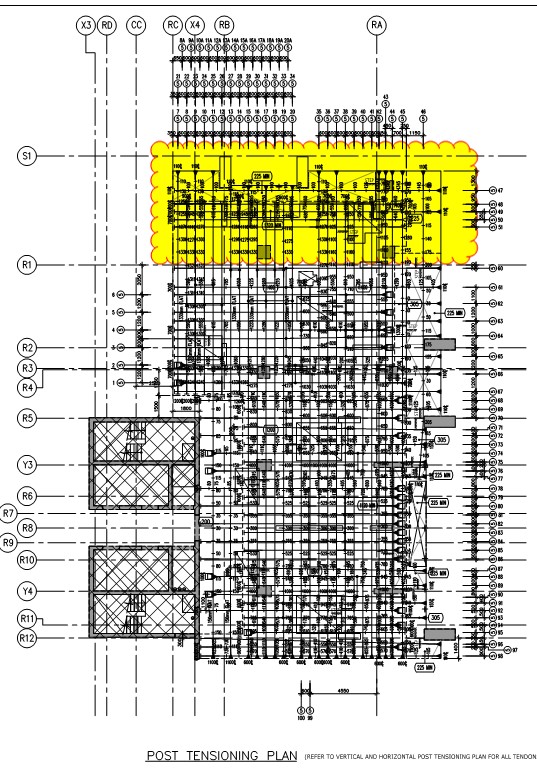

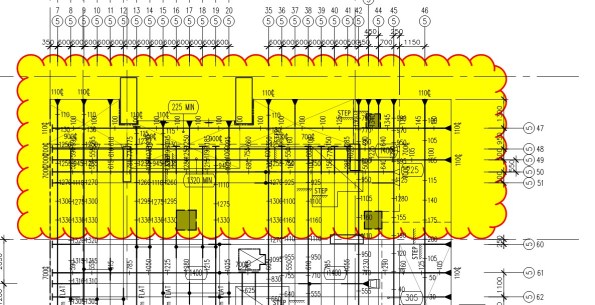

Anybody interested in what a site inspection of 1400mm deep, 5.5m cantilevering transfer beam designed to support 18 storeys looks like…

The PT is made up of 15.2mm diameter strands @ 300 centres. The cantilever supports 18 storeys with only 20mm deflection!

The construction of this was not simple. PT design is not in the structural engineer’s package, it is in the PT sub-contractor’s. Their original design saw almost half the amount of PT shown in the photo but and deflection of 38mm. By the time the design consultancy had highlighted the need to restrict deflection to 20mm, the PT had been assembled as per the original design. You can imagine the look on the contractor’s face when they were told more PT was needed. Due to congestion, the additional PT could not be added in a side-by-side arrangement, but by way of a second layer in the vertical plane. The contractor was not happy.