Phase 3 – Week 1

At the start of this week I began my Phase 3 attachment with Ramboll in Birmingham. I am working in the Buildings department, currently tasked with an Energy from Waste (EfW) plant in Gloucestershire, this is a power plant that burns non-recyclable waste to produce power (E&Ms can tell you more).

The EfW plant is basically a series of huge steel structures with smaller concrete structures inside them. The loads from the mechanical plant in here pose the biggest issues to the designers, as well as another engineers designing the mechanical systems, they are also responsible for the steel work that supports this. Ramboll are essentially responsible for the housing structure and foundations.

In my first week I have been tasked with looking at the Boiler hall structure. An RC box that houses the turbines and boilers (big loads). The client initially issued loads on the agreement they would not increase by more than 10%. These have now more than doubled and I needed to assess whether the beams and columns were still sufficient at current sizes (increase in steel was presumed).

The critical beam was already 2m deep spanning 13.58m and the column this sits on is 14.75m tall (750mmx750mm). After my week of assessments (by hand) the beam has increased to 2.5m deep and the column is just about suitable. I have also now designed a new roof slab which sits on top of the Boiler hall with some water tanks and other loads.

I think I have just about got through the other engineers watching me struggle with hand calcs and lots of rubbing out, whilst everyone else bashes away at their computers. I will add some photos from the computer model when I have worked out how to Print Screen!

Chris, I’ll be interested in bit more about the system. As part of zero waste to landfill target at Gatwick, there’s an energy from food waste system being finished over the next couple of months. Currently planned just for food waste from the flights but likely to expand to terminals too. Who’s supplying the main items of the plant?

Hi Stu,

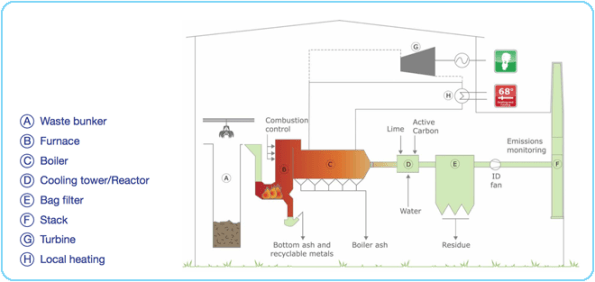

The project is being delivered by an Urbaser Balfour Beatty JV. See a summary of the system added to the blog – I’m sure this is over simplified, but it is pretty much my understanding for the processes.

We actually went to a similar project in Beddington (nr Croydon) and it is massive, if you get a chance to visit one then you must go. The contractor on the one in Beddington is CNIM. They are referred to as either Energy from Waste (EfW) or Energy Recovery Facilities (ERF).

As a quick answer to your question they have a good website (https://cnim.com/en/energy) and it’s worth a look. I will find out who the supplier on the Gloucester EfW is next week for you.

Chris, good to see someone else bashing away with hand calcs whilst the rest of the modern world does it on the computer! At Wentworth House they all use TEDDS to do the calculations on the computer (essentially you select the formula you want, add some values and it gives you a nice, neat word document with all the answers highlighted), what system does your office use? What 3D modeling system are you using?

Hey Fred,

Yeah Ramboll also use TEDDS – I’ve used it this week to check if my hand calcs and the software gave similar results – I found it was pretty intuitive to use. As you say you can just select what you are designing (RC Beam – EN 1992) and stick in the values. I’ve found the analyse & design option in the software not as reliable as the individual options to analyse first and then design – you get a few more options to customise your model this way.

The 3D modelling is all done in Autodesk ROBOT and the drawings and models can be viewed in some software called Trueview – also part of the Autodesk family.

I found TEDDS was limited when it came to analysing a slab with varying spans greater than +/- 15%. But you can get a pretty good model putting it through the beam software and modelling the spans you need. Obviously did a check by moment distribution by hand too!!

ROBOT has a pretty good resource of videos on Youtube for tutorials etc – but I found the best way to learn TEDDS was just to dive in and start playing around.