Archive

RPS Design Consultancy Belfast

As with all my contemporaries I have moved to the Design Office. My attachment is with RPS Consultants in the Belfast office and I am working within the Maritime Infrastructure Department. This blog is a brief scene setter so that my follow on blogs make sense.

RPS

RPS Group was founded in 1972 as Rural Planning Services (RPS) and labels itself a multinational energy resources and environmental consultancy company. The company is headquartered in the UK. In the 90s RPS expanded into Europe, North America and Australia. The company now employs over 5000 people worldwide, has an annual turnover of approximately £500m and in 2015 made a pre-tax profit of £57m

As part of the company’s expansion RPS Group acquired Kirk, McClure & Morton – a small sized consultancy, based in Belfast. The office employs approximately 200 employees. There are six departments, typical of many civil engineering consultancies: Waste & Energy, Transportation, Water & Environmental, Planning, Structures and Maritime Infrastructure.

BAE Surface Ships

I am employed on the BAE Surface Ships Initial Enabling Infrastructure (IEI) project. The contract comprises the design and construction of works to facilitate the build of The Royal Navy’s new Type 26 Frigates in BAE Systems’ Glasgow Shipyards. BAE Glasgow contains two shipyards along the River Clyde. BAE uses a modular approach to build the warships at two River Clyde sites; Govan and Scotstoun. The ships will be constructed in modules within large fabrication sheds at Govan. These modules will be welded together on a slipway on one shipyard and transferred onto a barge for launching. After the vessel is launched, it will be taken down river to another shipyard Scotstoun for final fit out and trials.

BAE Systems Glasgow – Two sites on the River Clyde

BAE Systems Glasgow – Two sites on the River Clyde

Initial Impressions

With a “smaller” consultancy I believe I will be exposed to a wider variety of engineering design rather than being pigeon holed in a particular design discipline/project. The counter to this is there is no dedicated specialists (Geotechnics for example) and knowing the SME requires knowledge of which personality designed the last/similar project.

The BAE project has a great deal of engineering design; in essence heavy Civils refurbishment/modification of old dock quays. Unfortunately, there appears to be a fair bit of Geotechnics which is disappointing as I was naïvely hoping for 6 months of steel portal frames…

Finally (and most importantly) it is great to spend some relaxing time at home with the family as the photo shows.

Paddy and Caffreys

Bryden Wood Technology Ltd

I have put my nose back to the grindstone after a short cameo as a ski instructor, starting my design office placement working for Bryden Wood Technology Ltd; a small design consultancy of around 130 people based in North London. The practice is focused on architectural design; however has a MEP team of around 20 who handle both the technical elements of multi-discipline projects and some stand-alone MEP projects. This blog is a short intro to what I will be doing over the coming two months.

My approach could be called unique….. It certainly isn’t efficient at the moment.

The first project I have got involved with is the construction of two leisure centers in North London; Copthall and New Barnet. Both jobs have progressed to ‘RIBA stage 3’ (developed design) by a different contractor and over the next couple of months our team will move it on to the next stage, producing a detailed technical design. So far this process seems like a chilled-out version of the PET building services project; producing the loads, air changes and lighting requirements for each room and sizing plant and luminaires to meet the demands.

Anyone for a swim? North London…. bring a stab-vest.

I have been occupied for the first week designing the fabric of the building and selecting equipment to fulfill the requirements of Part L of the building regs (fuel and energy efficiency). The output of this process is a building energy certificate (or EPC) which is required to allow planning consent to continue as well as provide operating information for the end users. This is all carried out on a government-approved computer program called IES, which is basically a modern version of Hevacomp for grown-ups. Like much of the work in a design office, you are not efficient until you are conversant with the CAD.

The project is a big one for the MEP team, containing a chemical dosing and UV installation (for the swimming pools), a small CHP plant and a rooftop solar array. The project is fully ‘BIMed’, and uses Revit and subsequently Navisworks as the main platforms to accomplish the design co-ordination. The project is forecast to finish by the end of March – it should be a good exercise to get used to the CAD programs and the processes that take place in a design office.

Diesel generator + exhaust hot water heater = fuel efficiency. Doesn’t come cheap though.

Its early days, but so far the design office has been a bit of a culture shock compare to the site placement; to compare notes with the other ‘PETs’ I include some initial impressions:

- The nature of the work is very compartmentalised and ordered compared to the site placement. The hierarchy is well established and roles are well defined; with the discipline directors in immediate contact with their project teams. It seems it will be very different to the firefighting I became accustomed to on site.

- The financial aspect of a design is well defined; the company carefully measures the effort it expends on each project and scales effort to the agreed fee (generally fixed price); it is a big deal to ask for extra cash from the client. Again in sharp contrast to Crossrail!

- The office is simultaneously dealing with a large number of projects (in excess of 50); a number of these designs are scoping or concept only and will not be built; this is particularly the case for jobs in the pharmaceutical industry.

- The majority of the work is dictated by design standards, building regulations, codes of practices, etc.

- A lot of the thinking is done by computer programs which are not that intuitive to use. Hand calcs are done for initial estimates only, on a spreadsheet.

- Google Sketchup is awesome and industry uses it a lot…. This is likely to be the only program I can remember how to use when I come back to the Army.

Happy New Year

Conclusions on Pre-Fabrication

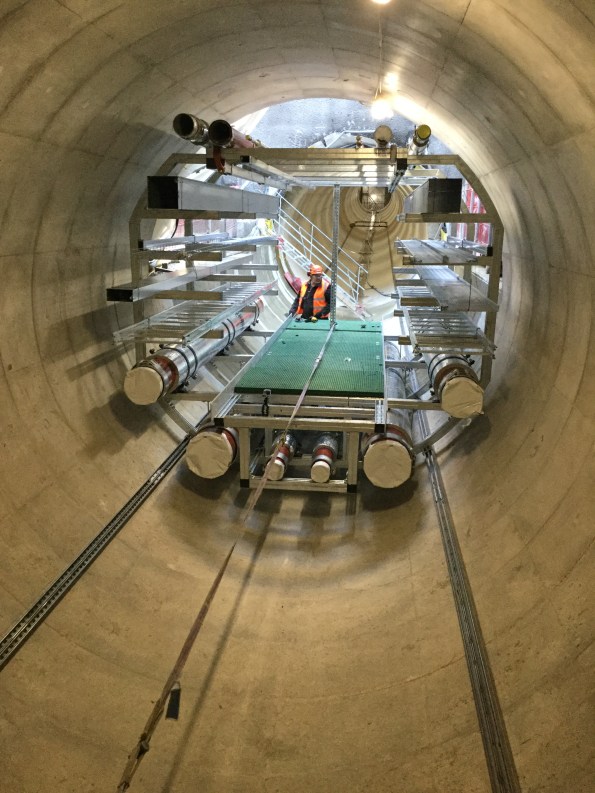

Pre-fabrication and off-site manufacture seem to be very popular in the UK construction industry at the moment and I have lucky to have been the lead on the largest pre-fab install on my project – a 132m long, 4m wide services culvert linking the two buildings currently being constructed.

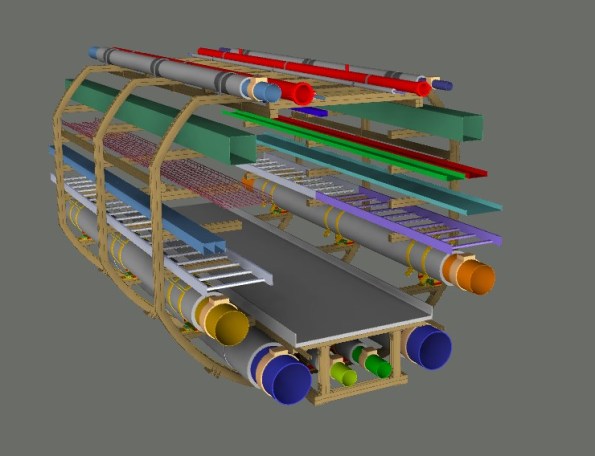

The install consists of 21, 6m long pre-fabricated modules with 12 modules installed on side of a central vertical shaft and 9 on the other. The modules carry chilled water, high-grade hot water, low-grade hot water, mains cold water, boosted cold water, sprinkler supply, HV, LV, ELV, Fire Alarms and Fibre-Optic Data. Water is transported through a series of cast pipes varying in size from 1″ to 16″ and the pipes are connected using Teekay Couples with a fixed point in the centre and expansion bellows either end of the tunnel to allowing for thermal expansion. All pipes are lagged and seated on slip rings. The cabling is fixed to a variety of containment (ladder racking and trunking) as shown in the pictures.

Background

During the procurement process, a study was conducted to consider the use of prefabricated modules in the tunnel rather than traditional on-site MEP install using Unistrut bracketry. This study estimated the cost to traditionally fit out the tunnel to be £745,757. The study concluded that there could be a saving by using pre-fabricated modules manufactured off-site. Since my project uses BIM Level 2, the required module was subsequently modelled in 3D and inserted into the consolidated building model. In my opinion, BIM significantly reduces the design risk when designing complex modules or bespoke structures and for us the ability to model each module in 3D and then move it through a virtual 3D tunnel using the as -built information from a laser scan was invaluable and actually led to the height of the modules being reduced as it was clashing with a low point in the tunnel.

Once the design had been agreed and approved by the Principle Designers (BDP), it was sent to Skanska Fabrications for a mock-up to be constructed.

As the install lead I visited the mock-up a few times and was able to provide feedback that led to design changes that would make the install easier (one such improvement was to set back the low level Unistrut that forms the walkway to give better access to the pipe connections and Teekay couples – you can see the issue in the above photo).

Once the design had been amended and agreed upon, the package to manufacture and deliver the 21 modules was put out to tender and awarded to Balfour Beatty Engineering Services (BBES) for a sum of £460,805. Although this looks like a significant saving on the £745,757 estimated cost of traditional install, other costs need to be factored in before a true comparison can be made. In addition to the manufacture fees, the installation costs (which I tendered under my own package) totalled £86,325, the cost of realigning and connecting the pipe work was agreed at a cost of £55,493 and connecting the electrical containment has been quoted for at a cost of £11,500. This brings the total cost of manufacture and installation to £614,123 which is about 18% less than the estimation of the traditional install and has been hailed as a significant saving to Client. This cost does not take into account the additional cost of designing a more complex system and comparing the costs to an estimation is unreliable as the costs could have been over-estimated. Therefore I believe the actual saving, if indeed they was any, is actually quite small especially since a traditional install would have procured through a 2-stage competitive tendering which would likely result in a contract sum that is less than the estimation.

One of the greatest advantages of pre-fabrication is that you can remove it from the critical path in the programme and reduce the time required for on site install. By manufacturing off site you can manufacture early and store the products rather than having to wait for an area to become free or for interfacing/preparatory work to be completed. However what I have found in reality is that the time to design a pre-fabricated solution is much greater (especially if modelled in 3D using BIM) and so although you may plan to construct early, manufacturing can be delayed by the design and drawing production which is what has happened on my site. In my case, the manufacture was delayed due to a lack of drawings (this is general issue on my project!) and this in turn meant that the tunnel was left empty and ready for the modules while the modules were still be constructed meaning that there was no real time saving. Infact, if we had gone down the route of traditional install then we would have fitted out the tunnel earlier than we did.

A disadvantage of pre-fabrication is that the design needs to be agreed and fixed earlier in the programme which then creates a greater risk from design changes later on.

Installation

The tunnel modules were installed as follows:

First of all a rail was installed by my sub-contractor using a jig-system:

Then the modules were dropped down the central shaft using a crane and dropped onto the rails:

They were then dragged into position using a winch:

Unfortunately the installation did not go as smoothly as the above description and I had to make changes both to the method and the state in which the modules were delivered. Despite this, we installed the first module on 24 Nov 16 and the last module on 12 Jan 17. Now we have to finally align and then bolt together all of the modules before we can realign and connect the pipework and containment. Then we can also take a site measure and construct the ‘make-up section that sits in the centre of the tunnel and will fix the pipework to the tunnel wall (required for expansion).

Snagging

Inspection of the installed modules has highlighted several issues. The first is that most of the pipework is out of alignment and so will need moving in order to be connected. The mechanical sub-contractor is arguing that the amount moving and aligning required is beyond the scope of their contract and so are requesting an instruction and extra cash. It is my belief that the pipes have moved during transportation due to cyclic loads. The pipes are on slip guides and the slip guides are fixed to the modules using Unistrut channel nuts (zebedees) which rely on friction to provide a fixing. Therefore in theory all of the pipes could move if forces are applied to it outside of the design conditions. A lot of the containment is also out of alignment.

Another issue is that some of the modules do not fit together as some of the walkways and kick plates stick out too far. This makes me question how the modules were jigged at the factory – a concern I have raised with BBES. However the greatest issue with the install is that some modules are sitting noticeably higher than the others. I am still investigating the reason for this but believe it can be only one of two possibilities:

- The rail is high in places which could be due to a poor install or imperfections in the tunnel itself -several were picked up on the laser scan!

- Some modules were incorrectly constructed or mis-jigged.

Either way I need to come up with a solution and so I am looking at ways to reduce the overall module height.

Given the variety of snags and issues, I have assembled a multi-trade team using 4 sub-contractors that will go through each module and adjust every pipe, rack and section of trunking to allow all the modules to be moved as close together as possible which will minimise the gap between the pipework (maximum allowed gap is 8mm). This team will start next week which gives me a few days to work out how to lower some of the modules!

Conclusion and Recommendations

It is my experience that the conventional understanding that using pre-fabrication saves time and reduces programme risk whilst increasing costs is incorrect since on my site we have seen the exact opposite. So far on Project Laureate, using pre-fab has led to on-site delays (with knock on effects on other packages) and has cost less (18% less) than a traditional install. However, it is worth noting that this could be unique to this site due to the scale and complexity of this install or the selection of materials. Also the cost of the traditional install is reliant on an estimation which may not be accurate.

Prior to conducting this task it was my understanding and the understanding of my colleagues that the modules would arrive on site and line up perfectly, reducing the amount of time required for the on-site fit-out. Again this has not proved to be the case as none of the modules fit together without remedial works and extra time is now required for realignment. I would urge anyone running a similar task in the future to assume that any bespoke modular system being delivered to site will need a certain amount of realignment and adjustment on-site. At the very least this requirement should be priced as a provisional sum during tendering and should be included in the programme. This is particularly important for large and complex structures or systems with several variables (e.g imperfections in the final structure or multiple connections).

During the design of a module or pre-fab structure, assume that the structure it will be installed in is riddled with imperfections and plan against this to reduce the risk of delays and additional costs during the install. This could be done by adding a means of adjustment in each axis. Although this will incur additional costs, in the long it will likely save money.

When considering loads on the structure or system, also consider the temporary state such as transportation to reduce the risk of structures deforming or equipment shifting. This could lead to the requirement for bespoke bracing or supports that be will used during delivery to site.

Regularly visit and ask your sub-contractors to visit the factory during manufacture to provide feedback and to facilitate design changes that will make the install easier.

Although this package has proven to be an engineering challenge and is my greatest headache at the moment, would I use off-site manufacture again? Yes I would as I still think if done right it can offer either cost savings or time savings. However, I would implement the points above and would most likely tender it out as a design and build package to reduce the risk of delays due to an overstretched Project CAD Team. If using a Project CAD Team, I would recommend only considering the use of pre-fab for complex installs if BIM is the primary method of design.

Mark, can I count this as TMR 4?!