Archive

Remember these John?

As many of you will know I have opted to stay with the BP Exploration Operating Company Ltd (BP) for Phase 3. I am remaining with the Projects and Modifications (P&M) team and so will continue in a mainly Project Management role. In order to gain design competency I will be taking on work from the Discipline Engineering (DE) team. One of said pieces of work involves this:

GEC CTU15 Relay

No, not a flux capacitor. This is an obsolete mechanical protective relay from the aging Magnus platform; E&Ms will remember studying these in great detail with John Marsh. The problem is that being obsolete there are no spares available if any fail, which some have started to show signs of doing during routine testing.

BP Magnus

The task for DE is to find a solution which doesn’t involve replacing/modifying 35 year old feeders, air circuit breakers, bus bars and current transformers or 39 electrical cabinets. The Magnus’ high voltage transformers and feeder setup are a bit of a unique design and even replacing the existing current transformers would be at best challenging and at worst dangerous. Unless you shut down the entire platform, which at $1million per day production loss isn’t going to happen.

My job is to engage with a vendor who claims to be able to utilise the existing relays to develop a plug and play digital replacement. This may be using the existing casing or an interface plate to install a contemporary relay in the existing Magnus cabinets. If the solution is viable and passes a FAT, I will need come up with a plan of prioritising the replacement of relays on the platform, the testing procedures and the programme for installation. There will inevitably be quite a number of discrimination curves to draw too. Best I jump on Air BP to Manchester and undertake some vendor engagement…

Concept Design…

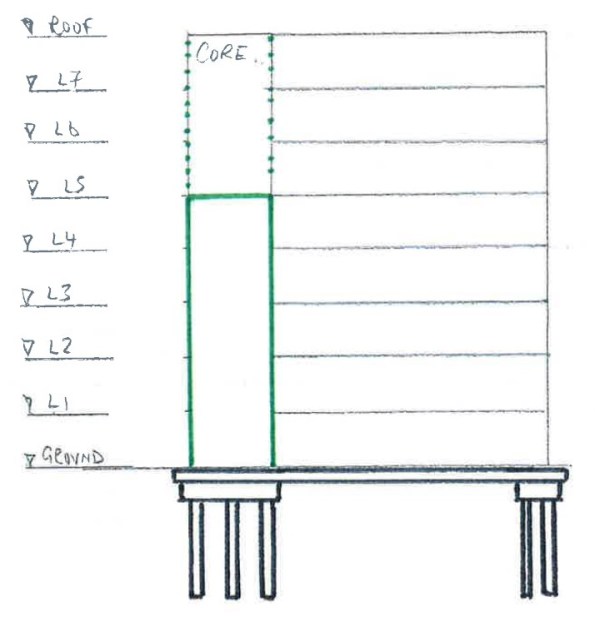

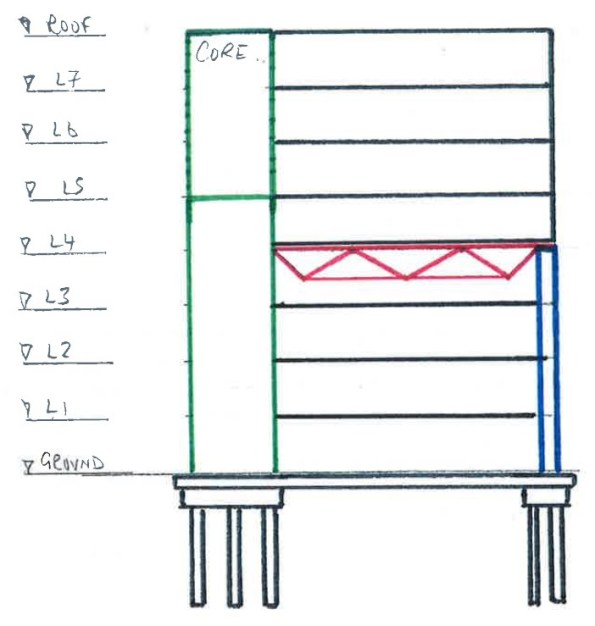

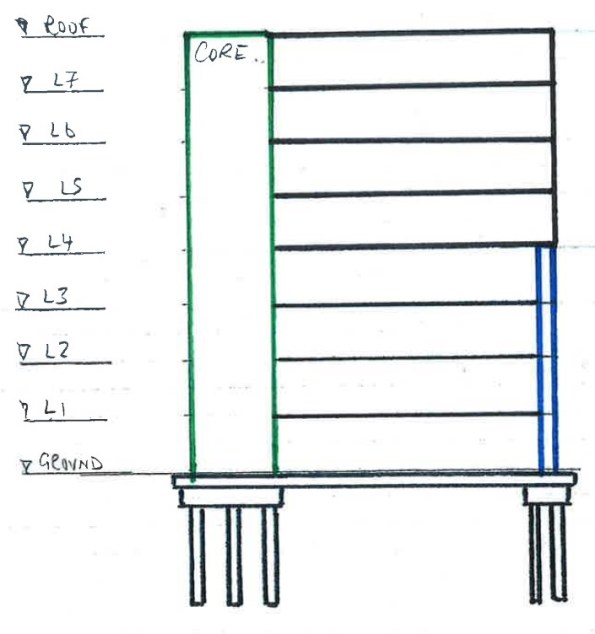

A potential client, wanting a 7 storey building, is keen to discuss the advantages of ‘beneficial occupancy’. Interestingly the most valuable floors are levels 4 to 7 and as such, these are the priority. Having been approached with this request, RBG have offered a concept design which allows the contractor to programme the more valuable, upper levels ahead of the lower.

Step 1: Foundations and raft slab (black)…

Step 2: Jump the core (green)…

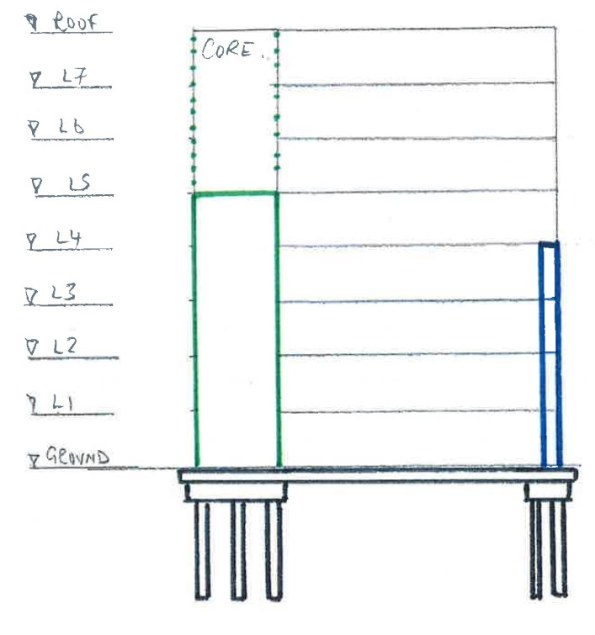

Step 3: Once the core has reached the required height (level 5), secure 15m prefabricated column (blue)…

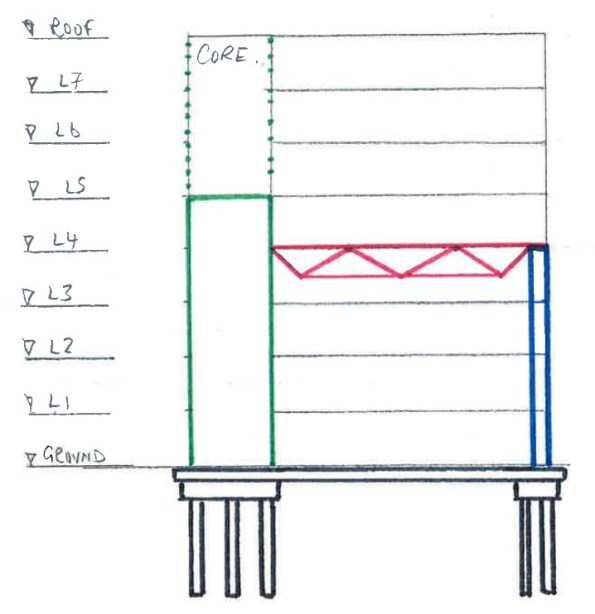

Step 4: Connect column to core at level 4 with prefabricated steel truss (red)…

Step 5: Infill level 4 with precast slab and then progress concurrently through levels 5 to 7 and ground to level 3 using conventional falsework.

Step 6: Remove truss.

Whilst simple, this approach delivers the most valuable areas of the asset to the client earlier than conventional methods. It also negates the need for a ‘deep beam’ arrangement at level 4, maintaining level 3 headroom.

Unfortunately due to commercial sensitivities, I haven’t been allowed access to the cost benefit analysis of this approach. I have however been informed that whilst this approach costs more in materials, it delivers the most valuable areas of the asset sooner. The earlier delivery of levels 4 to 7 translates to an earlier profit for the client. This advance of profit offsets the inflated cost of materials.