Archive

Technological innovation in construction

I’ve been involved on the periphery of a few discussions with innovation in construction recently so I thought i’d type out my musings in case I want to use it in the future. Plus i’ve just ordered on Deliveroo so i’ve got some spare time tonight. Unlike the beautiful “E&M cut and pastes” from a TMR it’s not neatly formatted, more like the words have just fallen out of my head (akin to JMs feedback).

Firstly I attended a talk at the ICE on technology as a management tool, delivered by Highways England (should be available as a recorded lecture soon at http://www.ice.org.uk/recordedlectures , along with other videos for filling a boring winter commute). They’ve seen tangible improvements in management or delivery from technology in the following areas:

- Remotely Operated Temporary Traffic Management System (ROTTMS)

- Stationary vehicle detection software to prevent, detect and monitor incidents.

- Integration of design, operational, construction and environmental risks onto BIM 3D modelling.

- BIM 3D and “4D (cab view)” safety briefing and supply chain planning.

- Real-time view of national traffic conditions via the National Traffic Info System (NTIS).

- A digital component library – “design once, use repeatedly” (although you need to be careful that the use of standardised designs doesn’t stifle innovation).

- Drone surveys – reduction in risk to manpower on highways

- Data acquisition and analytics during construction to develop a “Haynes manual for construction”.

- Live task monitoring and reporting of progress, resource levels, reserves etc.

However, despite the successes above they admitted that introducing innovative technology is not straightforward. I’ve read that BIM will mean we don’t need to rely on physical surveys anymore. Great news, but as they said in the presentation, surely we shouldn’t have had to do that since CAD was first used if it was properly employed. Therein lies the problem, before introducing a new technology you first need to make sure the people and processes are ready for it. Definitely a lesson in there for the military (MAKEFAST?, MOSS?, JPA?, ORIENT?)

Look at the people (why are they not already doing it and are they ready for it?) look at the business model and processes (what is the need and what are the limitations?)

Barriers to adoption of technology can include confusion (certainly in my case), training burden, hardware and software costs, data storage costs, security of data, reliance on specialist personnel for operational continuity and what if it all goes wrong?

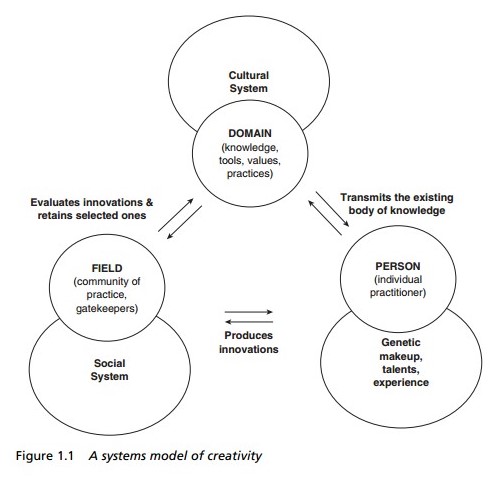

I attended a workshop on innovation as a test for some training the Think Up are delivering (https://thinkup.org/) and this presented a similar idea to that which I think was first coined in a systems perspective of creativity by some author with a crazy name full of consonants (http://www.sagepub.com/sites/default/files/upm-binaries/11443_01_Henry_Ch01.pdf).

He presents it diagrammatically as:

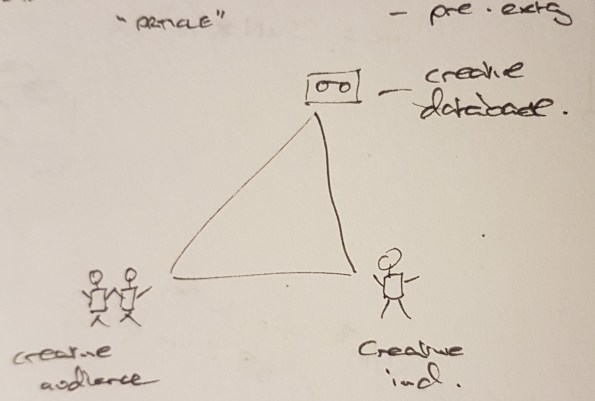

I prefer my own notes from the workshop:

The workshop concluded with a discussion on how Expedition can encourage innovation internally. There were many suggestions including having a “dunce in residence” to ask seemingly stupid questions that then spark innovation (a role I am happy to fulfill), more talks from suppliers, innovation reviews at key design stages. They were enthralled by my suggestion of “tea & toast” as a useful discussion forum when I said the military do it. They thought it showed the military as a creative and forward leaning organisation allowing daily sessions for open discussion of ideas without an agenda. I did point out that it was just an opportunity to eat toast and occasionally drink port but I think it may make an appearance in the office soon.

As a look forward – the next installment will feature how we can use innovative materials. There may or may not be a quiz afterwards with Champagne (Asti) up for grabs.