Archive

Formation level at Hinkley Point C

I’m currently not allowed to upload photos onto this site – I’m trying to sort out permission from site. So I will keep it brief until I can provide a decent intro to site with some phots. I just wanted to show the formation level on the site where I will be managing the install of the main site office (OIC portacabins). There is a 48hr exposure rule due to oxidisation of the ‘blue lias’ rock which can become weathered very quickly, so I’m lead to believe. So the inspection and blinding is fairly slick to minimise further excavation to fresh rock. Is this level of cleaning excessive in your experience? Or good practice? (Conscious that this is a picture – but it’s just stones) Dan Porteous.

Angel Gardens Teaser – Darwin Award nomination

Stadium Australia

Built for the Sydney Olympics, Stadium Australia originally looked like this…

After the Olympics, the stadium was expected to attract smaller crowds and so the terraces behind both goals were reduced. This modification has resulted in the present day configuration, see below.

The owners now want to make two further modifications. Now that the running track is redundant, the first alteration will see the seating brought much closer to the pitch, adding to the capacity and atmosphere. The second alteration will see the addition of a roof, see below.

Whilst both endeavors are intrusive, the alteration of the seating arrangement is the greater challenge. This is because the trusses which span over the length of the stadium were designed with a roof in mind – bonus.

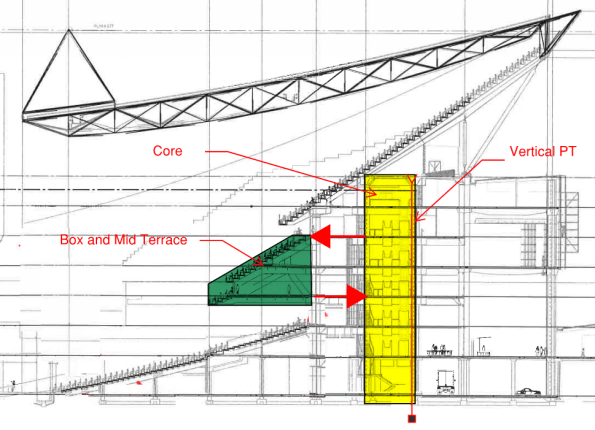

The box and mid terrace which run the length of the pitch are cantilevered from the main structure. The lateral push / pull loads are transferred to the core via the floor plates. Without a balancing load, this would cause the core to deflect towards the pitch. To counter this, vertical post tensioning runs the full height of the core, on the wall furthest from the pitch, see below.

Key: green = terrace, yellow = core, bold red arrows = forces in floor plate, red line at back of core = PT.

To reconfigure the seating, the box and mid terrace will need to be demolished. The requirement therefore is to identify a methodology which allows the removal of the terrace without causing an unacceptable imbalance with the post tensioning.

My first intention is to track down the original construction methodology. Has anyone else been exposed to the modification of PT structures during their Phase 3? Suggestions on a post card please…

Piling case pulling out reinforcement – Request for advice.

I am working on Phase 2 of the Battersea Power Station redevelopment, inside the power station itself. Within this I am managing the piling package inside the Boiler House, which in way of orientation is the main, central building of the power station, with the towers and chimney in the corners.

I have recently encountered my first issue, and although we have found a solution to allow construction to continue, we have not found the cause. I was wondering if anyone has any previous experience of this and knows the cause, so that hopefully I can prevent it happening again.

The design for this pile had the toe depth located in London clay, and as such the casing was used to seal into the clay, but no further, with the undrained strength of the clay allowing the rest of the bore to be drilled without the need for bentonite support. However, after over drilling beyond the London clay layer and into the aquifer below, and with the bentonite plant not yet operational, further casings had to be used to prevent the Thanet sands from collapsing into the bore. With this new depth a pile redesign was required, resulting in little more than a longer length of reinforcement cage needed, which was spliced on, and the concrete pour went without incident.

A total of 30m of casing was installed on this pile, far more than had been designed for, and it is when the casing extraction began that the issue arose. As the second section (3m) was extracted, the reinforcement cage rose with the casing. The cage had somehow become stuck in the casing and was being pulled out with the casings. Bauer (the piling contractor) were unable to push the casing back down, and after numerous attempts to rectify the situation, Bauer made the decision to remove the entire cage for the pile, and core through the existing pile to form the new one.

Unfortunately the first (top) splice joint in the reinforcement cage failed (it was not designed for tension with a load a wet concrete on it) during the casing extraction, and only the top cage (approximately 12m long) could be removed. After several hours of failing to dig out the cage (I believe the concrete was still too wet) it was left as is. Currently the dip to concrete is 7.3m from ground level and there is 8m of casing on, but lifted above the concrete.

It has been decided to backfill the void and to place a new pile either side, with a capping beam on top, rather than try to rectify this pile. Space allows for this and schedule is the driving factor, with this being put forward as the quickest solution.

Where I am after advice is what caused this to happen. Currently there are 2 possible options being discussed, but I am having difficulty accepting how either of them could have caused the issue. I have outlined the options and my thoughts on each below:

- The cage was simply caught on the teeth of the casing. The spacers should have kept the cage away from the teeth, and if this was the cause then I can struggle to see why only the top cage was caught. It would make more sense to me that the entire cage would be pulled up if it was caught on the teeth. Or am I missing something?

- Grout loss during the pour. If there was a large amount of grout loss then could the denser concrete and increased aggregate have simply jammed the cage into the casing? If this grout loss was towards the top then I can see how that could explain why it was only the top section which was jammed, but I fail to see how there could be grout loss inside a casing?

If anyone has any further information on either of these options, or has other theories to throw into the mix, then please get in touch. I have about 200 piles to go and would like it if the rest went more smoothly!

Slope Stability – Safe or not safe?

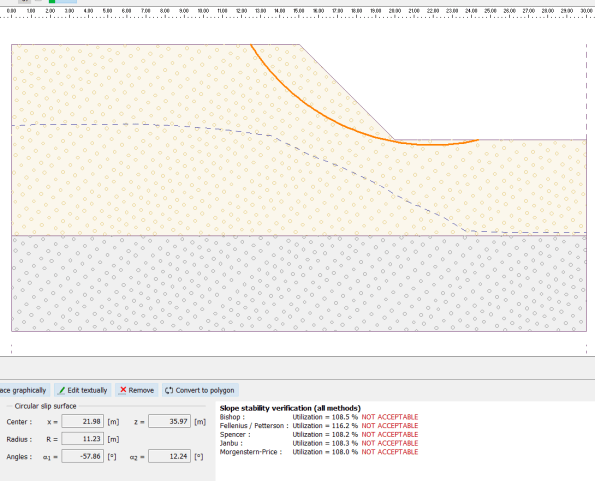

Figure 1 – 45 degree slope with 80T crane surcharge

Whilst wondering around site during my first couple of weeks I couldn’t help but notice the slope in the picture situated in River Terrace Gravels. Having now read the GDR I know the design phi dash of the River Terrace Gravels to be 33o. Therefore a design angle of Beta at approx 60o. When I queried a couple of the site/section engineers the response was that they always cut a slope at 45o and then step it if it is a larger slope. The layer below the River Terrace Gravel is London Clay and I would agree that for the short term in clay this would be sufficient, relying on the undrained shear strength. However is the design of 45o in the River Terrace Gravels acceptable?

Firstly a slope cut at 45o would still suggest a safety factor of 1.3, assuming that the pumping of ground water has reduced the ground water regime profile of the water level to below any slip surface. There is a sump reducing the water level to approximately 3m below the toe of the slope, so I will make this assumption.

I modelled this case in Geo5 (Figure 2), producing a result of instability. Geo 5 was showing failure in DC2 but not DC1. This is because DC2 is more conservative where a gamma factor of 1.25 is applied to the tan phi dash, reducing phi dash to 27o. As this is a temporary load case and we know phi dash will not be as low as 27o is this suitable for a temporary works solution?

Figure 2 – Slope modelled on Geo 5

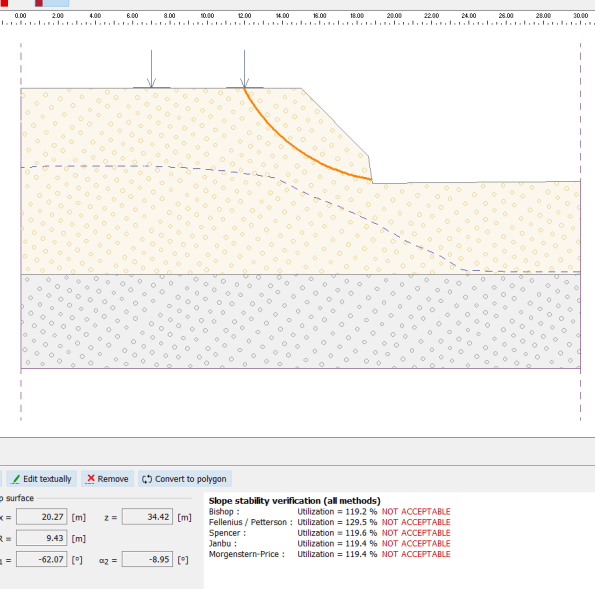

Moving on – As you will see in my photos there is a crane (80T) operation at the top of the slope, therefore once you take this load and factor by 1.3 (NA to 1990. NA.A1.2(C)) and re-model in Geo5 you can see it fails with a larger rotational slip. The crane is in fact sitting on a 400mm deep concrete blinding but I cannot model this without Geo 5 ignoring STR failure in the concrete pad. If I ignore the pad then obviously the situation is worse but the principal the same.

Figure 3 – Slope modelled with surcharge

The gamma factors in the Eurocodes are there as guidance and therefore I would argue temporary works is the ideal time to reduce them if considered safe to do so by the engineer (allowing for other factors). Is this an example of just such time when the ground seems to be behaving as expected or is this too great a risk. However currently there is no temporary works design for this slope and the surcharge inflected by the crane; so I would suggest it is too much of a risk!

One Nine Elms – How not to design a structure

So, hello everybody. I hope everyone is settling in well and the Australia lot are not too sunburnt. In order to not bore everyone by just regurgitating AER 1, I intend to give you a brief overview of my site and then discuss the main issue with the project.

HEALTH WARNING – it’s a long one, sorry.

One Nine Elms – Multiplex

I am currently a site engineer for Multiplex on the One Nine Elms project. Multiplex have been brought in by Wanda (the client) after a number of contractors had walked away, being unable to agree on price and the project was showing little progress being almost a year behind schedule. The current contractual arrangements are slightly confusing but in essence everyone is currently under contract directly to Wanda. Second London Wall (Employers Agent) are the clients advisors and Multiplex under a Construction Management contract, but with not direct control over the sub contractors. All this makes for a confusing and rather inefficient site however, Multiplex will be moving to a Design and Build contact in June with the client becoming Second London Wall. I suspect this will be a future blog or TMR once it becomes a little clearer.

Fig. 1 Architects Impression (Left) and Superstructure 3D (Right) – notice the lack of St George Wharf completed in 2014

The site is the redevelopment of the Market towers, two 23 storey RC towers completed in 1975 and demolished by McGees in April 2015. Piling and groundworks began on site during the demolition and is not likely to be complete until the early 2018 which I will elaborate on below.

Superstructure

The superstructure consists of two high rise buildings referred to as the City Tower (yellow) and the River Tower (blue), the towers are linked at the first floor with a link bridge via a podium (purple). The City Tower is 56 storeys assigned for residential occupation, with the River Tower being 42 storeys with the upper levels being for residential occupation and the lower levels assigned as a hotel along with the podium. The structural concept for both towers is typically post tensioned reinforced concrete solid slabs supported by composite concrete encased steel columns and a centrally located reinforced concrete core. The reinforced concrete core along with its buttresses provide the lateral stability to the building, floor plates act as diaphrams restraining columns and transfer lateral loads to the core.

Substructure

There are two basement levels across the whole site with a third level between the two towers. A 1750mm combined sewer runs through the middle of the site which splits the substructure in two. Groundwater cut off is achieved by two 800mm diaphragm walls boxes either side of the sewer which have a toe depth in the London Clay. The foundations supporting the Superstructure consist of 256 compression and tension bored piles acting in conjunction with the raft at B2 level. These piles vary in diameter ranging between 1800mm and 900mm with the toe in the Thanet Sands. Due to the proposed construction sequence some of the piles contain plunge columns.

Ground Conditions

The ground below the site is typical of London and consists of Made Ground (depths between 1.1m – 4.90m), Alluvium (depths between 4.5m – 9.5m), Kempton Park Gravel (depths between 7.5m – 23.0m), London Clay (depths between 22.0m – 31.5m), Lambeth Group (depths between 10.5m – 16.2m), Thanet Sand (depth between 9.2m and 13.0m) above the Newhaven Chalk Formation. Groundwater is between 3.7m and 6.4m deep and is known to fluctuate, with the level of the Thames. Fig 3 below shows the Lithology along the route of the sewer, there is a scour Pingo feature in the East of the site and it can be clearly seen on the right below.

Construction Sequence

The original squence and design was for top down whilst constructing the two tower cores on a number of plunge columns simultaneously, in theory reducing the project duration. However due to issues with the sewer which I will outline below the sequence has gone to pot and now looks like bottom up around the River Tower and top down around the City Tower.

Sewer Issue

As mentioned above, the site sits directly over an existing Victorian masonry combined sewer. The Market Tower (old building) basement structure spanned over the sewer and was supported on piles either side with a 1.3m to 1.5m exclusion. Where superstructure columns landed within the exclusion zone a 2m deep slab transferred the load to piles either side. The same solution has been proposed for the new building – First error!

The option to construct a new sewer around the perimeter of the site was tabled at a cost of around £2 million, this was rejected by the CEO of Wanda. The reason cannot have been for cost. The 150m of extra diaphragm wall, two 2m deep steel transfer beams, fabricated out of 200mm thick plate which take down a main load path over the sewer and the 1000 tonne crane to lift them in will cost significantly more. Mental!

Having made the decision not to construct a new sewer, the next worst possible decision would be to let the achitects put the taller of the two towers where the scour feature is. Hence requiring a greater number of larger piles to carry the larger loads in more difficult ground, which raises issues of conflicting with existing piles….. You guessed it. The core of the 56 Storey City Tower is smack bang over the sewer and in the worst ground. Not only this but due to load exclusion zone the two huge transfer beams mentioned above are now required. Mental 2!

So you would think with everything mentioned above, a detailed internal monitoring system of the sewer would be wise to compare displacements to expected values….. Nope. Wanda decided it didn’t want to waste money installing a detailed monitoring system during the demolition (against the advice of pretty much everyone involved in the project), instead opting for an Invar rod and tube system on the crown of the sewer. These are cheap but have numerous disadvantages, such as not being very accurate being suceptible to temperature change and being surface laid are easily tracked over and disturbed by plant.

Analysis was conducted to estimate the sewer movement during demolition (heave due to a reduction in effective stress in the clay) and settlement during the construction of the D Wall and permanent structure. This analysis predicted vertical sewer deflections of +27mm during demolition, +63mm during excavation and on completion of the superstructure of +28mm (que a JM rant on accuracies in geotechnics). An interesting point here is that the new structure makes a better job of spreading the load across the footprint of the site, hence the heave remember JMs voids ratio v effective stress.

As can be seen in Fig 4 above, the coring of existing piles for construction of the D wall seems to suggest about 50mm of settlement, combined with 200mm of settlement known to have occurred before 2013. This puts the sewer way beyond the allowable strain stated by Thames Water (TW). The large jumps and the rod resets (black lines), raise the question of the reliability of the results but if this is all you have then it has to be trusted.

As a result of this settlement TW have imposed a 7.5m load exclusion zone either side of the sewer, until its integrity can be guaranteed . This effectively makes the completion of the piling impossible and blows the programme to bits. The current solution is to line the sewer with a steel liner, this maybe jacked down the sewer or lifted into place by cutting out the crown. These are subject to TW approval of the method. This work will take 30 – 40 weeks which is a direct delay to the project, as the effected areas are on the critical path and at an unknown cost (this will be a subject of a future blog). On top of this the D wall and key piles for transfer beams can not be done until after the sewer remediation. The clamshell rig leaves site for another job next weekend, leaving an incomplete GW cut off and a fairly large bentonite farm in the only area where work can continue. This is a pretty big issue, these rigs normally require a big lead time, booking for 9 months or more and have a significant establishment cost. Due to the depth required and then associate problems on achieving interlock due to tolerances, a secant wall solution may not be possible. The resultant of this is Wanda considering purchasing their own clamshell rig at a cost of £1.2million and MPX under considerable pressure to demonstrate to the client that are worth there margins.

Sorry for the long one, I’ve probably glossed over some vital information so fire away.

Bouncy Bridge

Good news! If you are a person who takes to train to Luton airport and have to deal with the shuttle bus to the airport terminal, worry no more. The owners of the airport have realised that the fact you need to take a bus to the terminal is putting off people travelling to their lovely airport and are doing something about it.

Arup have been working on the design for an automatic shuttle system (MPT – Mass Public Transit); think North to South Terminal at Gatwick Airport. Which will whisk you from the National rail platform up an escalator to a footbridge and into the Airport terminal in 4 minutes.

You may have seen an article in the press/ NCE magazine.

https://www.newcivilengineer.com/latest/115m-luton-airport-rail-link-tender-out/10017758.article

https://www.newcivilengineer.com/latest/details-revealed-for-luton-gateway-bridge/10017973.article

Network Rail Footbridge

As part of this project, over the last 3 weeks I have been working on the design of a steel footbridge structure which will span over the rail tracks at Luton Parkway Station. The bridge will connect into two lifts (which are self-supporting) and five escalators supported by bridge superstructure.

The bridge itself is a continuous steel vierendeel truss (I had to look into vierendeel trusses to realise that a vierendeel truss isn’t actually a truss, but this point is probably for another blog). The bridge is supported on three pairs of portal frames that sit on the station platform supported by piled foundations. All sections are welded rectangular steel sections. The shape of the portal frame is unconventional and is driven by the architects to maintain as much clear space under the bridge to increase sightlines. It is this shape which is starting to cause problems.

There a number of loads and combinations acting on the portal frames however the main variable loads are from the bridge and the escalators. Which act to destabilise the portal frame. Its easy to realise that the shape isnt the best for a portal frame. As the frame is loaded at mid-span the horizontal members want to straighten an overturning moment is generated to topple over the tallest column.

- Main Variable Actions on the Portal Frame

- Deflection of the Portal Frame

3D modelling

I have generated a model of the bridge in GSA (design programme written by Arup) to compare against my hand calcs and to model the 3D element of the structure. the age old problem of whether to model the frame with pin supports or moment connections raised its ugly head.

Modelled with pin supports deflections at the top of the escalator are about 40mm. Although no one can tell me what the allowable deflection for an escalator is I am assuming this this is too high. Does anyone have any experience with deflection in escalators? If I fix the column supports I can reduce the deflection to what I think is a more manageable 15mm however this generates a 2MNm moment which needs to be restrained. Meanwhile, I am looking to shorten the span from 18m though this requires negotiation with the architects.

Dynamic modelling

Arup’s experience with ‘bouncy bridges’ is quite developed following from history that people are happy to talk about. Arup are responsible for the millennium bridge fiasco though I am reliably informed by tony that the engineer responsible no longer work with Arup and works at Tony’s placement.

The dynamic response of bridges has been an interesting learning curve. Eurocode 1991-1-4 states that if the wind response frequency is above 1Hz then a dynamic check need to be conducted anyway. I have conducted a dynamic analysis of 10 modes which only considers the dead and superimposed dead loads. Unfortunately most modes have frequency between 2Hz and 7.5Hz, which puts it at risk of user induced oscillations.

These are videos of two of the dynamic modes of failure. In both the deflections are severely exaggerated but they are interesting and show the movement. You can also see that the deflection is largely as a result of the portal frame. Hopefully the videos work.

The second largest movement is due to the articulation of the bridge. The bridge is fixed to the portal frame at the centre on a pin bearing which means that all lateral forces are resisted in a rather small portal frame (2.75m wide) acting in the minor axis of the section.

Next Step

The design is still developing so there is still further to go. I initially left out the floor plate from the model as I wanted to be conservative. However by including it should stiffen up the lateral movement. I have also arranged a meeting with the architects to see how we can reduce the span or even the angle of the portal frame.

Watch this space.

Airport East; Demonstrating the Ground is a Risk.

Background

Sydney Kingsford Smith Airport and Port Botany are two of Australia’s most important international gateways. The roads around the airport and Port Botany are becoming increasingly congested due to the rising numbers of passenger and freight vehicles. The Airport East Precinct project will support the development of the West Connex motorway, which will improve access between this area and Western Sydney.

Project Overview

The Contract is for road and rail bridge construction on General Holmes Drive, Botany Road, Wentworth Avenue, Joyce Drive and Mill Pond Road in the east precinct of Kingsford Smith Airport at Mascot.

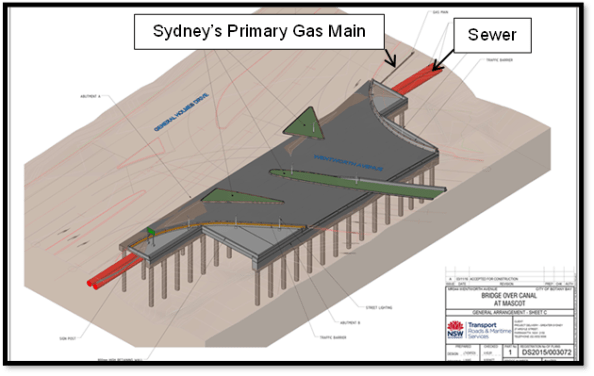

As site engineer I am currently overseeing elements of the installation of a new two span reinforced concrete bridge linking the new Wentworth Avenue underpass to General Holmes Drive (GHD) shown in figure 1 and tendering for the precast bridge planks.

The site is heavily congested and restricted, an active freight railway line dissects the centre. A sewer, high pressure gas line, and canal also create obstacles which have load limits imposed on them; therefore manoeuvring machinery is posing to be a real headache. There is also a vertical limit of an obstacle limitation surface; this defines the airspace surrounding Sydney Airport that must be protected from obstacles so aircraft are free to descend without interference landing.

Figure 1 – Bridge Linking GHD to Wentworth Avenue Underpass

Vibration Management

The east runway is undergoing maintenance from 24 March 17 – 3 April 17 which allows the tall piling rigs to be set up. I have noticed rotary aircraft using the eastern side of the runway so have suggested that red warning lights (complying with Civil Aviation Authority Standards) are attached to the top of each of the piling rigs and included in the activity method statements.

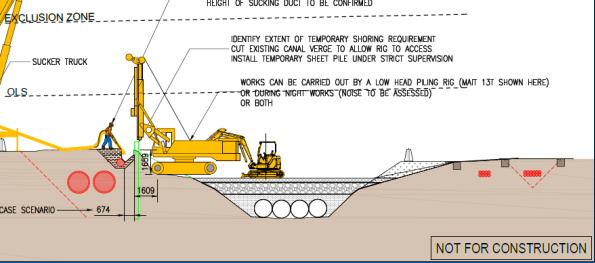

Figure 2 – Non-destructive Excavation & Sheet Piling Stage

A sheet pile wall will be installed adjacent to the primary gas main that will serve two functions (figure 2);

a. Retain the existing ground profile and allow for backfill around the gas main to eliminate any potential settlement or subsidence through piling and bridge substructure works.

b. To provide robust sacrificial formwork for the capping beam / pile cap.

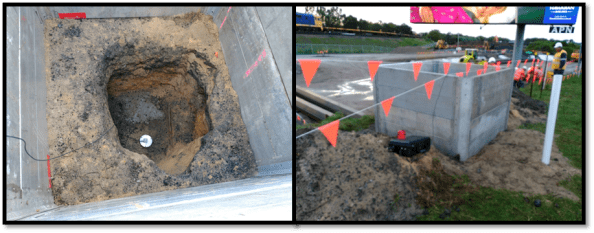

Prior to installation of the sheet pile, non-destructive excavation was used to determine the exact location of the gas main and extent of stabilised sand backfill around the services (figure 3).

During the sheet piling, vibration monitors have been installed along the sewer and gas main to record vibrations which may occur. Limits of vibrations which cannot be exceeded for the gas main are 20 mm/s and 5 mm/s for the sewer. If the vibration limits do exceed this, a silent piling rig will be utilised. I have questioned these figures as I was asked to research ground borne vibration on buildings within the area and DIN 4150-3 limits peak particle velocity to 3 mm/s on sensitive buildings.

Figure 3 – Vibration Monitoring of Gas Main

The silent piler uses the ‘press in’ method, grasping the previously installed piles and establishing a reaction force from the negative skin friction and interlock resistance of the previously installed piles. Since the piles are pressed in this method does not cause any damage to the environment including neighbouring structures, assets or residents through noise and vibration.

Contamination

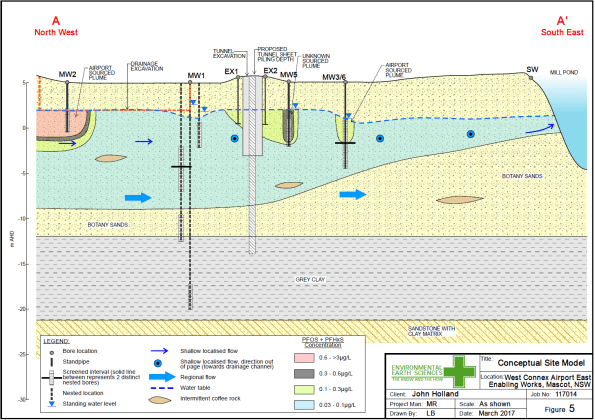

The project site is contaminated with poly-fluoroalkyl substances, known as PFAs. These are a group of manufactured chemicals contained in firefighting foam, they are added to improve the foams ability to smother fires. Therefore the likely source is Sydney Airport, the drainage for the airport runs through the site. The pathway and transfer of the PFAs is via the natural ground water flow through the site, and the possible receptors are workers and local residents as excavation occurs. They are a carcinogenic but are not found in high enough concentrations in the vicinity of the site to cause harm to workers.

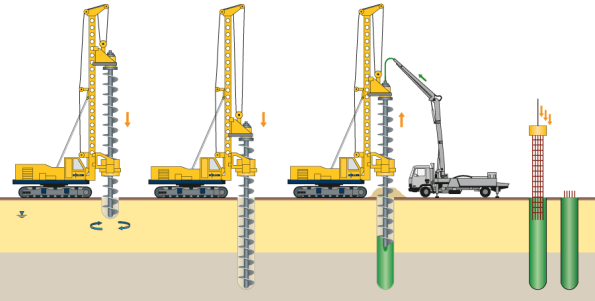

Continuous flight augering (CFA) piling is being used due to the poor ground conditions and lack of cohesiveness of the loose, brown/grey fine to medium SAND. This method of piling stops the excavation collapsing due the concrete being pumped in as the helicoidal auger is extracted to give positive pressure to the excavation walls.

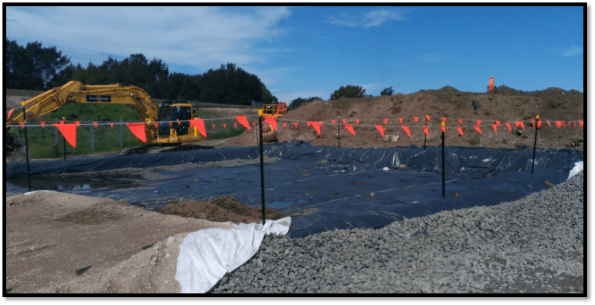

Figure 4 – PVC Barrier Layer for Spoil Heap to Limit Contamination

Excavated spoil is going to be placed in spoil heaps as to not contaminate the top soil. The PVC sheet is used as a separator and for the site to be compliant with the Australian Environmental Agency requirements. After looking at the design borehole (figure 5) for the site, I noticed the differing concentrations in PFA’s across the site. I have suggested that separate spoil heaps are created for different areas of excavation as to not waste money in disposal of contaminated waste which is has a different concentration of PFAs.

Figure 5 – Design Borehole for Site

CFA Piling Issues

As stated earlier the ground conditions are dictating that CFA piling is used. There have been some difficulties though when driving the cage into the poured concrete. Even though the water table is -3m AOD the loose, brown/grey fine to medium SAND is absorbing the moisture content of the concrete causing the concrete to cure quicker than expected. The concrete used has 240mm slump and aggregate size of 10mm (primarily to fit down the CFA tube). To overcome the issue 2m of concrete is being poured then immediately drilled out, lining the excavation with a layer of concrete to mitigate the loss in moisture content. Currently an excavator bucket is being used to push the cage into the concrete, but vibration of the cage is also being looked into. Thoughts on the use of a plasticiser?

Figure 6 – CFA Piling Process

IBM Greenford – Site Visit

Overview

IBM Greenford is a large tier 3 data centre, so it has a considerable amount of M&E equipment to keep the data centre running 24 hours a day and additional parts to increase the system redundancy in N+1 configuration. IBM has their own on site facilities management (FM) team, Kirby are the subcontractor doing the construction and Atkins provide the specialist electrical support.

I have recently visited site for a meeting regarding an issue with the new pumps being installed and to familiarise myself with the installation of the Uninterruptable Power Supply (UPS) system in the new purpose built building.

Pumps

The IBM site has an open loop industrial chiller system so the pumps supply water from an open aired tank to the chiller units. The old pumps are Worthing Simpson which are no longer available and are therefore being replaced by high efficiency Grundfos pumps.

The issue is the new pump kept going out of service and the FM team believe the pump is experiencing cavitation. The main cause of the problem is unknown; the meeting was exploring the potential causes and solutions with the contractor and an engineer from Grundfos via skype. Due to the issue with the pump, IBM want the pumps to be individually tested to confirm the performance matches the specification prior to installation and commission as soon as possible.

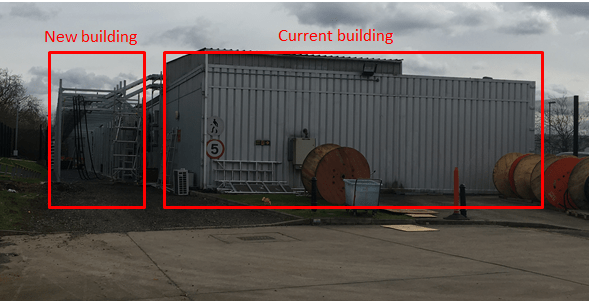

UPS

The new UPS system is being installed in a new building that has been built adjacent to the current East UPS system. Once the UPS system has been installed, each part will be individually tested before the system can be commissioned. A series of commissioning documents are currently being written by the construction team and will be reviewed by Atkins.

Below are some photos of the current battery rack and UPS control panels:-

That’s not a crack this is a crack!

![IMG_6764[1]](https://pewpetblog.com/wp-content/uploads/2017/03/img_67641.jpg?w=595)

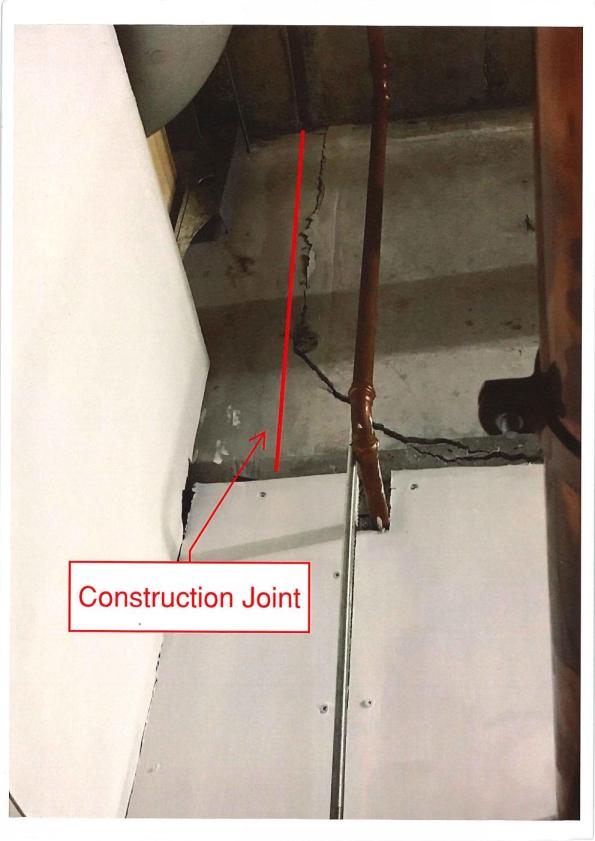

I thought BCT had problems! My boss and I were called in to investigate a crack at the Fortitude Valley Site. They are having some problems with their consultants. They have recently installed a crane and they thought it might have caused this cracking. It hadn’t what had caused the cracking was a construction joint that hadn’t been correctly designed. The connection had failed and there was evidence of shear cracks across the slab where the load had tried to redistribute. There are 20 floors of load on this slab!

Johnny Age 5 sketch

![IMG_6774[1].JPG](https://pewpetblog.com/wp-content/uploads/2017/03/img_67741.jpg?w=595)

This shear crack doesn’t look much but it shows that the transfer slab is in distress. Note the angle of the crack. Construction joint is above pipe

- Lack of specific construction joint for the transfer slab.

- The key of the construction joint was too close to the bottom of the slab. All of the vertical load was being transferred into the key detail at the bottom of the slab that then sheared off.

- In sufficient shear reinforcement.

- Construction joint located near an area of high shear.

- lack of oversight by structural engineers in Melbourne.

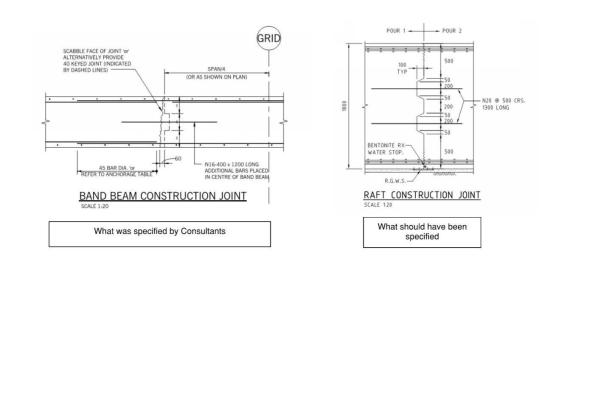

The Bad (what was detailed left) and good (detail from another site right). Note the key detail on the right and roughed finish

The offending construction joint before the pour. Note – no shear reinforcement and the key is close to the bottom of transfer slab!

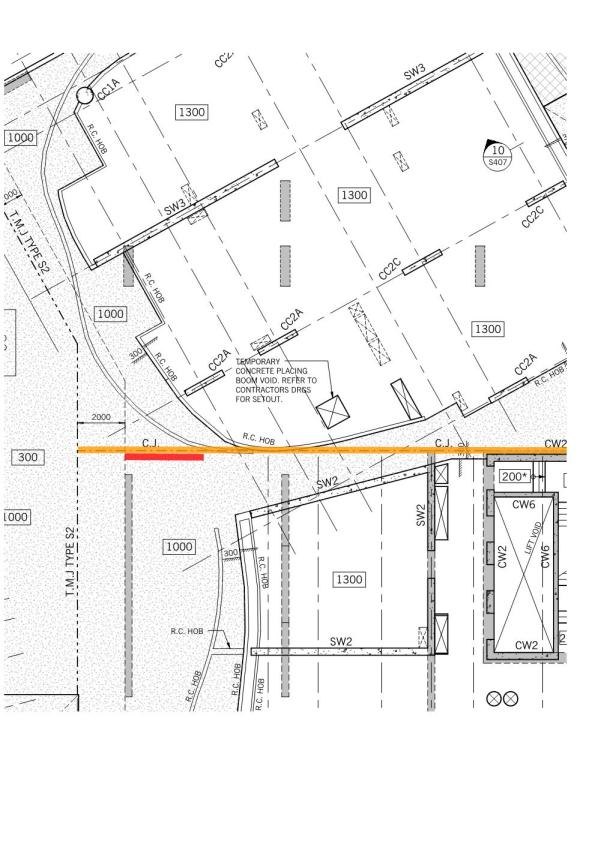

Plan view of the site (red is area of cracking). CC2A are columns that terminate at the transfer slab.