Archive

That’s not a crack this is a crack!

![IMG_6764[1]](https://pewpetblog.com/wp-content/uploads/2017/03/img_67641.jpg?w=595)

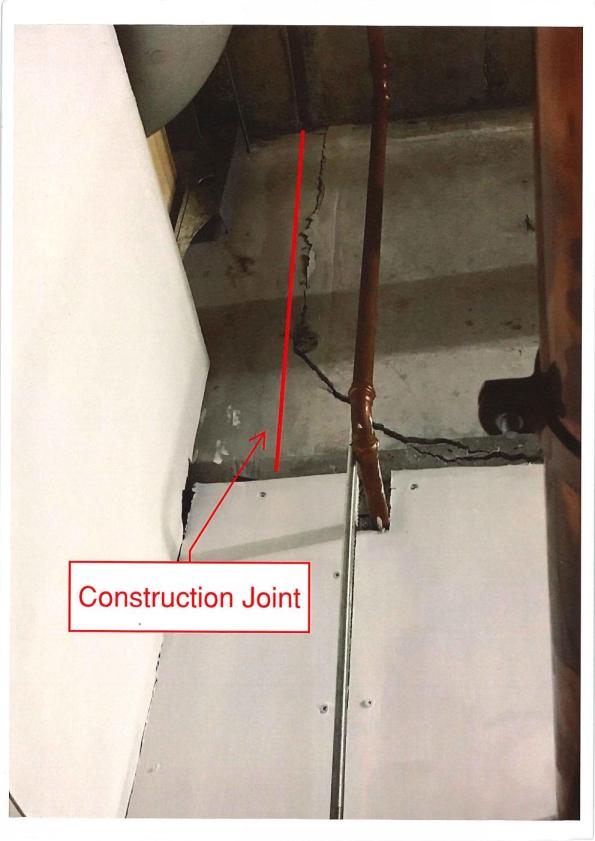

I thought BCT had problems! My boss and I were called in to investigate a crack at the Fortitude Valley Site. They are having some problems with their consultants. They have recently installed a crane and they thought it might have caused this cracking. It hadn’t what had caused the cracking was a construction joint that hadn’t been correctly designed. The connection had failed and there was evidence of shear cracks across the slab where the load had tried to redistribute. There are 20 floors of load on this slab!

Johnny Age 5 sketch

![IMG_6774[1].JPG](https://pewpetblog.com/wp-content/uploads/2017/03/img_67741.jpg?w=595)

This shear crack doesn’t look much but it shows that the transfer slab is in distress. Note the angle of the crack. Construction joint is above pipe

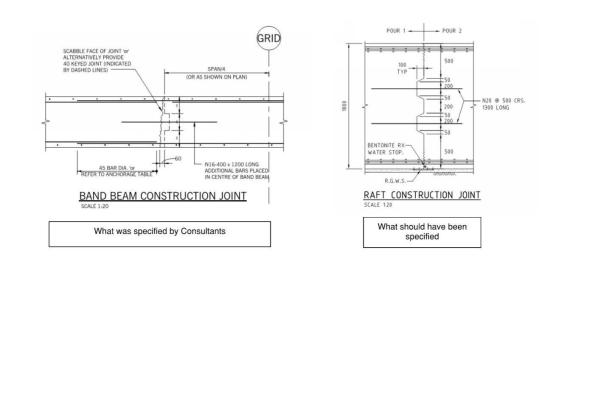

- Lack of specific construction joint for the transfer slab.

- The key of the construction joint was too close to the bottom of the slab. All of the vertical load was being transferred into the key detail at the bottom of the slab that then sheared off.

- In sufficient shear reinforcement.

- Construction joint located near an area of high shear.

- lack of oversight by structural engineers in Melbourne.

The Bad (what was detailed left) and good (detail from another site right). Note the key detail on the right and roughed finish

The offending construction joint before the pour. Note – no shear reinforcement and the key is close to the bottom of transfer slab!

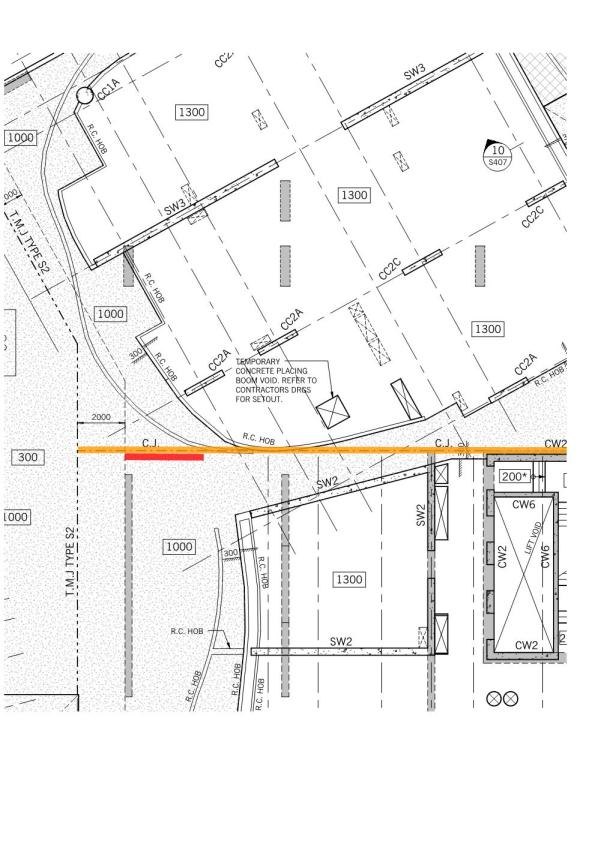

Plan view of the site (red is area of cracking). CC2A are columns that terminate at the transfer slab.