Archive

Stadium Australia

Built for the Sydney Olympics, Stadium Australia originally looked like this…

After the Olympics, the stadium was expected to attract smaller crowds and so the terraces behind both goals were reduced. This modification has resulted in the present day configuration, see below.

The owners now want to make two further modifications. Now that the running track is redundant, the first alteration will see the seating brought much closer to the pitch, adding to the capacity and atmosphere. The second alteration will see the addition of a roof, see below.

Whilst both endeavors are intrusive, the alteration of the seating arrangement is the greater challenge. This is because the trusses which span over the length of the stadium were designed with a roof in mind – bonus.

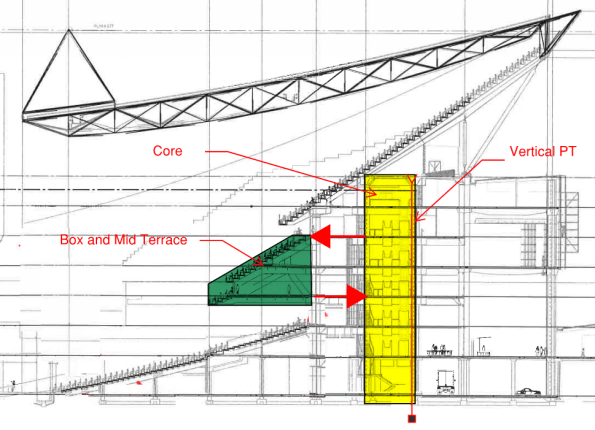

The box and mid terrace which run the length of the pitch are cantilevered from the main structure. The lateral push / pull loads are transferred to the core via the floor plates. Without a balancing load, this would cause the core to deflect towards the pitch. To counter this, vertical post tensioning runs the full height of the core, on the wall furthest from the pitch, see below.

Key: green = terrace, yellow = core, bold red arrows = forces in floor plate, red line at back of core = PT.

To reconfigure the seating, the box and mid terrace will need to be demolished. The requirement therefore is to identify a methodology which allows the removal of the terrace without causing an unacceptable imbalance with the post tensioning.

My first intention is to track down the original construction methodology. Has anyone else been exposed to the modification of PT structures during their Phase 3? Suggestions on a post card please…

Piling case pulling out reinforcement – Request for advice.

I am working on Phase 2 of the Battersea Power Station redevelopment, inside the power station itself. Within this I am managing the piling package inside the Boiler House, which in way of orientation is the main, central building of the power station, with the towers and chimney in the corners.

I have recently encountered my first issue, and although we have found a solution to allow construction to continue, we have not found the cause. I was wondering if anyone has any previous experience of this and knows the cause, so that hopefully I can prevent it happening again.

The design for this pile had the toe depth located in London clay, and as such the casing was used to seal into the clay, but no further, with the undrained strength of the clay allowing the rest of the bore to be drilled without the need for bentonite support. However, after over drilling beyond the London clay layer and into the aquifer below, and with the bentonite plant not yet operational, further casings had to be used to prevent the Thanet sands from collapsing into the bore. With this new depth a pile redesign was required, resulting in little more than a longer length of reinforcement cage needed, which was spliced on, and the concrete pour went without incident.

A total of 30m of casing was installed on this pile, far more than had been designed for, and it is when the casing extraction began that the issue arose. As the second section (3m) was extracted, the reinforcement cage rose with the casing. The cage had somehow become stuck in the casing and was being pulled out with the casings. Bauer (the piling contractor) were unable to push the casing back down, and after numerous attempts to rectify the situation, Bauer made the decision to remove the entire cage for the pile, and core through the existing pile to form the new one.

Unfortunately the first (top) splice joint in the reinforcement cage failed (it was not designed for tension with a load a wet concrete on it) during the casing extraction, and only the top cage (approximately 12m long) could be removed. After several hours of failing to dig out the cage (I believe the concrete was still too wet) it was left as is. Currently the dip to concrete is 7.3m from ground level and there is 8m of casing on, but lifted above the concrete.

It has been decided to backfill the void and to place a new pile either side, with a capping beam on top, rather than try to rectify this pile. Space allows for this and schedule is the driving factor, with this being put forward as the quickest solution.

Where I am after advice is what caused this to happen. Currently there are 2 possible options being discussed, but I am having difficulty accepting how either of them could have caused the issue. I have outlined the options and my thoughts on each below:

- The cage was simply caught on the teeth of the casing. The spacers should have kept the cage away from the teeth, and if this was the cause then I can struggle to see why only the top cage was caught. It would make more sense to me that the entire cage would be pulled up if it was caught on the teeth. Or am I missing something?

- Grout loss during the pour. If there was a large amount of grout loss then could the denser concrete and increased aggregate have simply jammed the cage into the casing? If this grout loss was towards the top then I can see how that could explain why it was only the top section which was jammed, but I fail to see how there could be grout loss inside a casing?

If anyone has any further information on either of these options, or has other theories to throw into the mix, then please get in touch. I have about 200 piles to go and would like it if the rest went more smoothly!