Archive

New arrival at Gatwick and a nugget for the Civils

Having received a detailed handover from Stu Douglas, I am now in the chair as an M&E Package Manager and currently involved in a number of interesting projects. The Department for Transport has imposed a directive on all major UK airports which requires Gatwick to install new baggage scanners to ensure they conform to the Explosive Detection System 3 Standard by 1 Sept 2018. The machines are larger in all regards, including size, weight and heat rejection, therefore there are multiple projects running simultaneously in order to install these machines; I will introduce you to these projects over a number of blogs in due course.

The Gatwick Airport estate is vast and is distributed across two terminals, North and South. The South Terminal opened in 1958 and has a footprint of 160,000 m2 and the North terminal opened in 1988 with a footprint of 98,000 m2, with a supporting workforce of 24,000 employees spanning 252 companies. GAL employs 2,800 staff directly which is sufficient to manage a throughput of 43.1m passengers in 2016. GAL is projecting that passenger numbers will increase to 52m by 2032 and the infrastructure must also expand to accommodate such a vast increase.

The airport boasts a colourful past, serving as an aerodrome in the 1930s and later requisitioned for military use for the RAF in 1940. The estate was renovated in 1956 to become a commercial airport paving the way for Gatwick to become the UK’s second largest airport. Figure 1 shows Gatwick in general with the South Terminal at the bottom of the image.

Figure 1 – Ariel view of Gatwick Airport.

Figure 1 – Ariel view of Gatwick Airport.

Gatwick is a heavily engineered and congested environment which makes the simplest construction project or electrical/mechanical installation very complex indeed. That said, I have come across a small construction project which may be of interest to the Civils. The principle contractor is MARCO (to be clear, this is not a person but the company name) whose brief was to Design and Build office space and a welfare facility for the Gatwick Handling Agents (GHA) to operate from in the South Terminal.

The project progressed well until the contractor had to excavate a 50m x 1m channel through a concrete base of 600mm to allow for soil pipes to transit waste from the toilets to a new foul drain. Figure 2 is a capture of the design drawing which shows the location of the toilets, pipe runs (brown) to the foul drain and I Beam columns (in the red circles).

Figure 2 – A capture of the GHA design drawing showing the area of interest.

The foul pipe from B to C has a cross fall of 1:80 and both the grey and black water is gravity fed to the foul drain at C.

Unfortunately the channel is in a confined space with a low ceiling and restricted access, therefore the contractor is unable to use diesel powered excavators and dumpers to remove the rubble. Consequently they employed the use of a portable control BROKK hydraulic breaker and then handball the rubble from site. The BROKK and channel is shown in Figure 3.

Figure 3 – BROKK and Channel

The BROKK is also shown in Figure 4 below, it requires an 15kW/32A 3 phase supply from a generator which can be remoted away from the confined space. There are larger machines on the market that can be hired, this is at the bottom end of the scale. The machine will produce a noise level well in excess of the HSE standard of 85 dB(A) therefore ear protection is required. The machine also produces a downward pressure on the tip at 25MPa.

Figure 4 – BROKK 100

THE PROBLEM

The vibration energy applied through the tip to the ground is transmitted through the concrete to the vertical I Beam columns circlied in red at Figure 2. The vertical columns connect to horizontal beams supporting the Departures Lounge and a number of retail outlets. The vibrations were having an impact on the outlets above and the Project Manager was summoned to Harrods to explain why their jewellery was dancing around the shop; as a result the excavation was halted with immediate effect. The noise level was measure by the on-site EHS representative at 76dB, to put this in perspective, employers must provide PPE to those exposed to noise above 85dB. Another 9dB increase then the customers in Harrods would be issued with PPE!

THE SOLUTION

At first, the PM suggested that disruptive maintenance is conducted in silent hours which is between 2300hrs and 0400hrs, however if this course of action was adopted, the contractor would fall behind considerably. The contract is an NEC3 Option E (Cost Reimbursable) which translates into delay costs which are imposed onto the client (Gatwick).

The second option was to cut the concrete channel beyond 600mm depth using an orbital cutter down to the compacted earth beneath, doing so detached the channel from the rest of the concrete pad. This simple act prevented the majority of the vibration energy being transmitted through the pad to the vertical columns. The BROKK was re-introduced and the noise assessment was conducted again during silent hours and a notable reduction was observed from 76dB down to between 52-54dB.

Both contractor, client and Harrods are happy once more!

Site Recce and My Last Blog

I was recently involved in submitting a tender for the construction of for a proposed development that had 3 x 30 storey towers and a common 3 level basement in Brisbane.

I was asked to look at where there were likely to be clashes of ground anchors and neighbouring structures. The image above is what I prepared to brief the bosses and contains a section through the development to show what the rock horizon is.

After conducting a desk top study I had to recce the site and determine what the likely foundations were and whether they could impact upon the ground anchors that would temporarily retain the basement. From the desk top study I has a good idea the ground profile but no idea of what the foundations of the neighbouring structures were. As the site was only 30 mins away I decided to take a trip out to visit.

As an interesting aside – the dry cleaners photographed above has been leaching chlorinated solvents into the groundwater that has now contaminated the whole site and meant that we have to vapour proof the entire basement because the of these volatile organic chlorinated compounds (VOCCs) into the groundwater.

We had previously looked at a soldier pile and panel solution to retain the basement in areas of good rock and then a water tight wall. This pile and panel solution would now need a bentonite lining and then vapour proof barrier. Attached is a sketch of the design I compiled along with the sub-contractor and environmental consultant. This is not easy to construct and is going to be very expensive as it needs to cover the whole basement. Given the new information the client has withdrawn the tender and is looking at possibly doing away with the basement altogether.

Scan-to-Me from 10 4 31 1 2017-04-04 074557

The end is very much nigh. The attachment to the Multiplex Queensland Head Office has been more beneficial than I initially believed. I have gained significant technical experience from a first class structural engineer but also a vast amount of contractual experience. I have had the opportunity to lead on geotechnical design and hopefully has provided me with some useful case studies for CPR.

In other news the family enjoyed one last holiday in the sun. It was very much needed after the thesis! Mark – bring on the photos of Namibia!

![IMG_6964[1].JPG](https://pewpetblog.com/wp-content/uploads/2017/04/img_69641.jpg?w=595)

Sam and Izzy (with friends) enjoying Fiji

Engineer Sketching – Recommendation for Phase 1 and Phase 2 Students

This is hopefully a quick blog with a basic recommendation aimed at Phase 2 students just writing their first TMRs and the students about to start Phase 1 at PEW. It’s probably a bit late for Phase 3 students just finishing off thesis.

Since starting work in the design office I’ve been surprised at how much time I spend producing sketches and technical engineer drawings. Id say approximately 55% of my hours are committed to this work rather than reading through code or churning the calculator. This is because the main method of communicating technical design detail is with sketches and drawings and generally clients/subcontractors tend to miss information contained in text when analysing a dwg. So far I have worked on three types of Dwg/Sketch:

- Engineering Concept Design – Used to provide general information on the way in which something is built. These are most commonly used in method statements and design proposals. As these are general concept dwgs they are normally produced by the Engineer because it is cheaper and quicker than getting a Draughtsman to do it. They still go the client so therefore need to be reasonably professional.

- Calculation Sketches – These sit in my calculation pack and are there to add context to a calculation process. Generally these are internal and are never formally assessed so these are quick and rough.

- Formal Drawings – These are the output Dwgs from weeks of design work and are the main method of relaying information to a client. These therefore need to be highly detailed, professional and accurate. As such these are always produced by specialist Draughties using CAD. This can take ages (weeks) and is very expensive, as such we only use this method when absolutely necessary.

So the advice focuses on the first of these three. I am terrible at making Dwgs look neat and professional. I spent a few weeks wondering how the guys in the office produced such exceptionally neat hand sketches. We even have a sketch of the month competition and my attempts were, until recently, a million miles away from winning.

That is until I found out there is free computer software you can download that helps you make rubbish hand sketches look good! As I started using it this week I thought it would be helpful for those students producing Dwgs for TMRs or those on Phase 1 producing sketches for the design problem coursework. You produce your rough sketch, scan it in then edit and add detail as required.

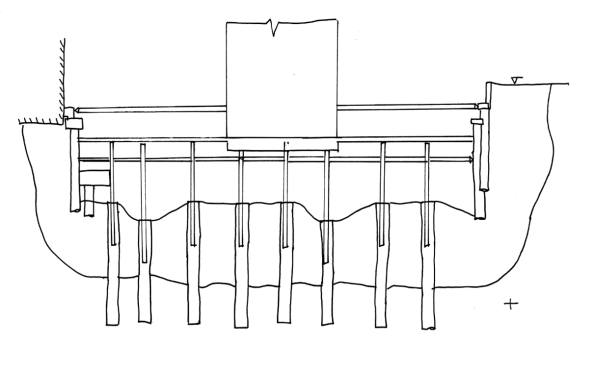

Here is my hand sketch, using tracing paper, for one stage of a basement construction method statement pre-software.

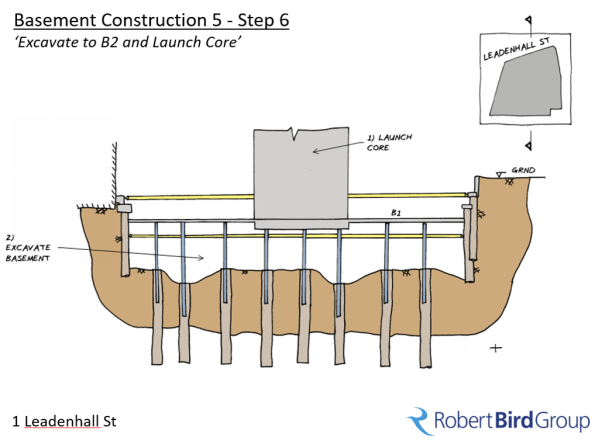

And here are a couple of my sketches after some computer magic.

Still rough I know but a considerable improvement! The software is called ‘Gimp’ (no joke). I’d recommend downloading it and using it for coursework.

S2 Kings Cross – Orientation

I’m now several weeks into my Phase 2 placement with Carillion plc and it’s time to break my blog cherry. This post will hopefully serve to provide a quick overview of the project and company with an emphasis on pictures rather than words!

Site Orientation

The King’s Cross estate is owned by, and being developed by the King’s Cross Central Limited Partnership. One of the largest redevelopments in London, the 67-acre site has a rich history and a unique setting. What was an underused industrial area is being transformed into a new part of the city with homes, shops, offices, galleries, bars, restaurants, schools, and a university.

Kings Cross Development Area (looking West) circa 2008

The S2 site is one of seven sites that Carillion currently have within the Kings Cross Development Area. Two other contractors (Kier Group and BAM Construct) also operate sites in the development.

Kings Cross Development Site Plan (Purple-Carillion, Red-Kier, Green-BAM)

S2 project Outline

Kings Cross S2 is a new £78 million commercial office development comprising; eleven storeys of grade A commercial office development, over; retail, lobby and further office space at ground floor level, over; deep single storey basement housing plant tenant cycle storage and changing facilities and welfare. Further plant is located at levels 10 and 12 with a tenant roof terrace located at level 11. The tenant is Google UK who have signed a 17 year lease on the development. As the initial tenants numerous aspects of the build conform to their specific requirements, including double height floor spaces to various areas and open lobby spaces

Architects image of completed S2

The building frame consists of a reinforced concrete basement and ground floor, with steel frame superstructure and composite floor system. Stability is provided via a central reinforced concrete core, which is formed around passenger lifts and stairs. The cladding system is a 1.5m unitised system, with a stone faced façade. Within the superstructure of S2 there are a number of cantilever floors and setbacks. On the south-eastern corner there is a large cantilever at fourth floor level.

The substructure consists of reinforced concrete basement and ground floor with rotary bored pile foundations into London clay. Contiguous piled walls on each basement wall provide temporary retention and permanent vertical support to columns.

S2 Progress – March 2017

Contract Information

The main contract between Carillion plc and King’s Cross Central Limited Partnership is a JCT (2011) Design and Build contract with Employers Amendments. The price and payment structure of the contract is based on a lump sum with interim stage payments. The contract seems to work well on the S2 project with its provisions for collaborative working and sustainability meaning there is a real team ethos between client and contractor with a shared effort when issues are encountered. The current completion date for the contract is March 2017.

A two stage tender process was implemented for this contract. Stage one was a competitive tender aspect between Carillion and BAM, both of whom were selected off the clients selected delivery team members list. Carillion was successful at stage one and so moved forward to stage two which was a negotiated element directly between the client (Argent) and the contractor (Carillion).

Roles & Responsibilities

My current role is as the Construction Supervisor for the superstructure on the S2 project. I work directly to the Package Manager (Construction Manager) for the superstructure/substructure. Given my parameters I liaise with the other Package Managers (Fit Out, Envelope and M&E) in order to expose myself to as many activities and issues as possible. My initial time has seen my attention focused on health and safety matters and quality concerning the steel erection and composite floor construction. This period has proved challenging at times with a steep learning curve endured with regards to the project and company processes, however, this has allowed me to immerse myself in the project and understand how the project it being run.

Summary

The S2 project seems an exciting project to be involved with. I feel the timing of the attachment has been well situated in terms of the project programme with a vast amount of activity currently being witnessed with numerous trades all working on site. As with probably all students my concern at this early stage is that I will be able to meet all the ICE Attributes in the time available.

I hope this post has been partly interesting in setting the scene. I will look to provide some site related engineering issues in the near future!

Sustainability through Design

Conscious that CPR is just around the corner and Sustainability still looks to me like a vague, tree hugging engineering attribute, I have volunteered to join the Robert Bird sustainability working group. Made up of engineers from varying disciplines (Geo, Temp Works, Civil’s and Structures) and experience depth/seniority, our objective is to develop a sustainability approach within RBG and provide focused support to ongoing projects.

In today’s meeting a senior project director asked us to look into a very specific client request to try understand the risks and opportunities from a sustainability perspective. In broad terms, the local planning department and client have mandated that 25% of all aggregate used in his project must be reclaimed. Though we have a 40 storey concrete residential structure in which we could potentially hide this high percentage of reclaimed aggregate, unfortunately the structural engineers have told us they do not want to use it in any columns or beams because they are concerned about its performance.

The interesting thing about this mandated condition is that we have no context to its origin or underlying intent. By that I mean we have no idea what the planning department aims to achieve by it or if it was just a random number plucked out the air by a Planning Department work experience undergrad ? Most of the team assumed it’s to reduce the carbon cost of the project. Someone thought it is intended to reduce the number of vehicles transported to site and one engineer suggested it is simply to save cost. At this point we don’t know.

Has anyone else encountered this requirement before and have any views on its impact?

We are now researching the following basic angles to increase our understanding of the options open to us.

- What is the key incentive for this planning constraint?

- If it’s to reduce the Carbon cost and we can’t get 25% reclaimed agg into the design, can we offset this shortfall with other C02 saving methods: ie use of GGBS or other cement replacement products?

- What are the structural issues with using Reclaimed Aggregate and how does it affect performance?

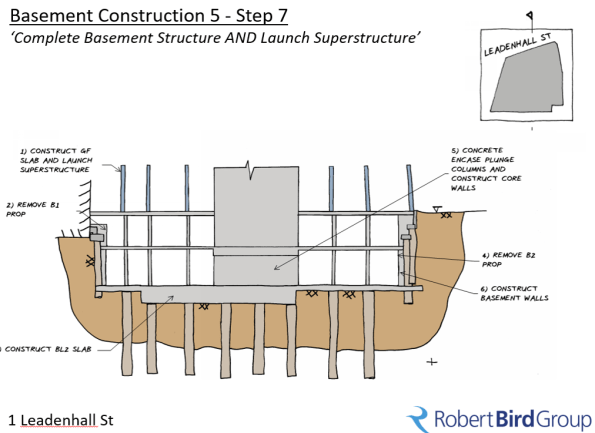

- At what point does using reclaimed aggregate actually add to the Carbon cost and are there suitable suppliers within range of task site? The following image shows that as the distance of transport to site exceeds 15km, the carbon saving is eradicated.

Anyone got any thoughts or experience of this stuff? In the meantime I’ll be chained to a tree at an anti fracking protest whilst waiting for answers.

Cheers

TD

Coming to America

I have just arrived on site so this initial blog will be light on details and my actual role within tasks has yet to be finalised but I thought I would post something so as to get into the habit and as a method of recording information and actions that I can refer to when needed at a later date.

My first 7 months will be spent at Fort Detrick with the United States Army Corps of Engineers (USACE). Historically, Fort Detrick was the center of the US biological weapons program from 1943 to 1969. Since the discontinuation of that program, it has hosted most elements of the United States biological defense program. Originally the site was intended as a location to centralise all research into infectious diseases. Technically this did happen but as with the UK, people didn’t like sharing their train sets and there are now four completely separate facilities dealing with infectious diseases, each belonging to a different agency, one belonging to the Army, one to Navy, one to Homeland security and one to the National Institute of Health (NIH) in Fort Detrick.

I will be working on the new United States Army Medical Research Institute of Infectious diseases (USAMRIID) site. This is due to replace the original USAMRIID building which was built in the 1950s. The site includes Entry Control Point (ECP) 9 (Yes this means there are at least 8 other entry control points on campus) and the USAMRIID itself. ECP 9 has entered its testing and commissioning phase which I am involved with while the USAMRIID has entered the “red zone” meaning it is 80% complete.

ECP 9 is 4000 square feet building that will act as the primary entrance for all foot traffic into USAMRIID. The building is completely independent and uses Solar power for domestic water, a boiler for heating, two transformers (one for the building itself and one for the nearby parking area lighting despite the fact that there are already two other external transformers supplying said parking area), a back up generator and cooling tower. My hosts were quick to confirm my initial impression that this was the most over engineered guard room in an already secure base.

While receiving my orientation I witness a member of the Department of Public Works (DPW) call a stop to the testing of the air-conditioning as the individual doing the testing was “unable to demonstrate with enthusiasm” that the system was functional. The USACE have a standard “script” that must be followed during the testing and commissioning of a building. Failure to follow results in a big fat no. Does a similar “standardised script” existing in the Royal Engineers? Perhaps construction in Kenya would have been of a higher standard if there was a script for OCs, who themselves would not be subject matter experts, to follow when testing and commissioning or doing a handover/takeover.

Also as part of the testing and commissioning, videos for the use and maintenance of all equipment in the plant room is produced by either the contractor who installed it or a representative from the manufacture. This removes any possibility of those in charge of maintenance once a warranty ends claiming they haven’t received proper training. Once again this would have been beneficial in Kenya although closer to home I can’t help but think that the coffee maker in the Officers Mess would have benefited from something similar.

Oh and Regans complaints on fuel consumption are pretty ridiculous considering I bought this…

Musings on cyber security

I recently attended a very interesting talk at the ICE about what engineers can do to defend against terrorism (especially cyber attacks).

With this in mind I think design offices are fairly guilty of being slack when it comes to security of data. A quick rummage through the office server (which is not encrypted and I imagine would be easy for any potential hackers to access) I found, amongst other things, the detailed design for an ammunition storage plant in Beirut. Closer to home there is the structural designs for many a building in central London.

So, fellow PETs, do any of your design offices have actual security measures in place? I think this will be a growing concern in the future.

Remedial works to shoddy piles

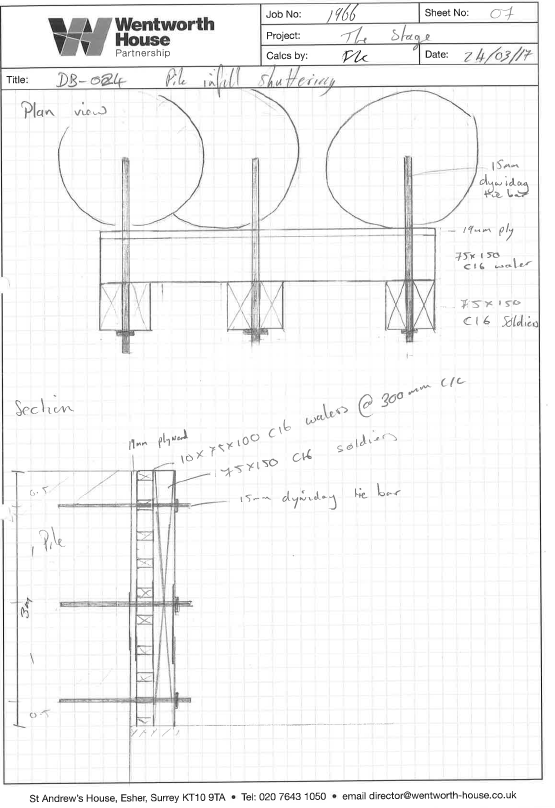

A quick blog on some activities I have been doing at Wentworth House Partnership (WHP). As part of my responsibilities for temporary works design for WHP I have been tasked with coming up with solutions to piling NCRs that have occurred at The Stage.

Prior to Keltbray taking over the piling contract a significant amount of piling works had been completed by a different contractor. This contractor had walked from/ been removed from the job because their methodology that they specified at tender wasn’t going to work. A large section of secant pile wall had been installed by these contractors prior to them leaving. This pile wall is to allow for the construction of a 2 storey basement. During the excavation of the basement a number of piles in the existing wall were noted to be raking into the basement area (out of tolerance for verticality), having large amounts of inclusions and/or evidence of mattressing of the pile rebar cages. These defects have been noted after 5m of excavation, a further 10m is still required.

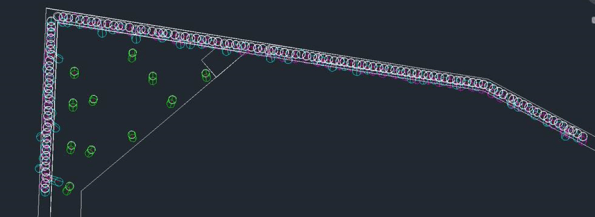

3D Modelling has been used to assess how much the raking piles were intruding into the basement footprint.

As can be seen from the image the existing secant pile wall is supposed to be installed where the white circles are. The dark green circles indicate the location of the pile at a depth of 15m. This is based on examining how far they are out of tolerance at a depth of 5m and extrapolating. A number of piles are raking significantly into the basement. These piles will have to be broken out and reinstalled. The plan for this is to break the pile out in sections and pour a concrete column to replace it. Analysis is ongoing to establish the effect of removing a pile from the wall. It will more than likely be limited to the removal of one pile at a time otherwise there is a risk of the whole wall failing.

It can also be seen that a number of piles are raking away from the basement. This will result in large gaps in the wall which will allow water ingress into the basement. In this case a relatively simple formwork design has been designed in order to allow concrete to be poured into the gap. To limit the pressure on the form work I specified that the pile infill must be done in 3m high sections. This will also allow the contractors to do the infill sequentially as the excavation continues.

The above a sketch that I drew for the formwork design. This sketch was then converted into CAD by the CAD technicians so that I wasn’t giving the contractors a Freddie age 5 drawing but actually something with a whiff of respectability.

BSRIA Design Checks

Short and sweet post, thesis calls.

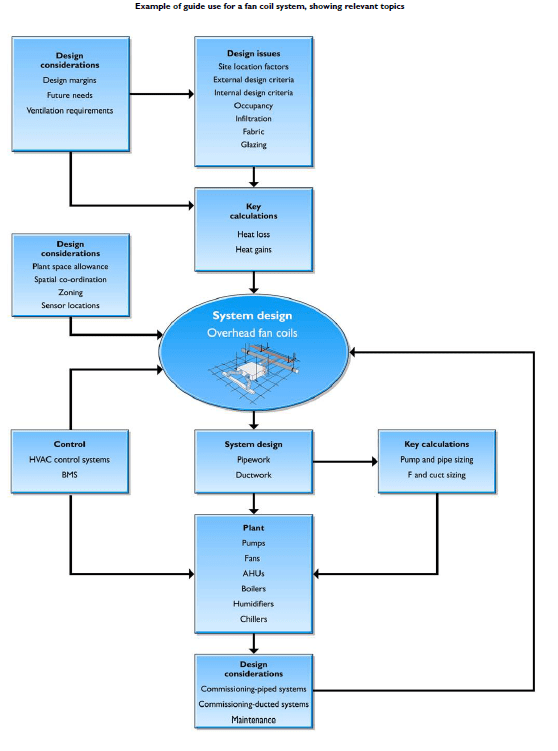

I have recently discovered the BSRIA (Building Services Research and Information Association) design check guides. There are a number of booklets for different elements of a building services design (e.g. HVAC systems, variable flow water services, electrical services, etc)

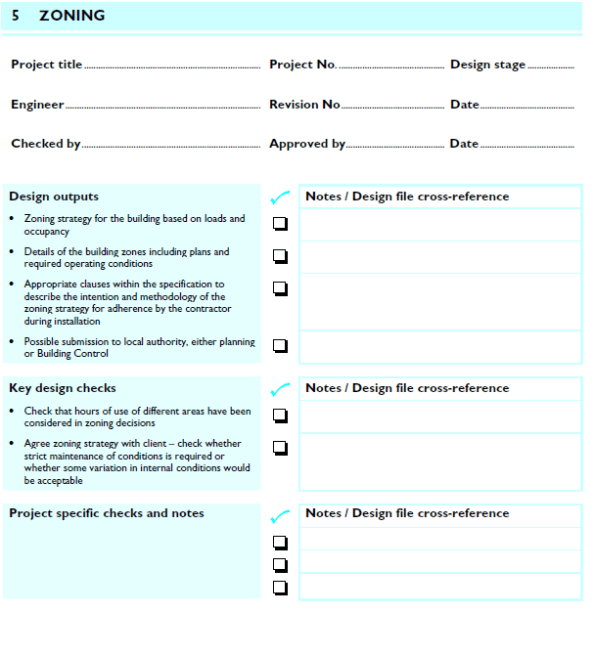

Each guide lays out a map of the design process, lists the relevant standards and legislation and contains a detailed checklist of things to consider. Some examples of the content for the HVAC booklet (the one I am using now) are shown below.

These booklets are used by Bryden Wood to provide a quality assurance record during the design process. They are not freely available, but most design offices should be able to get hold of them. If you need something in particular over the next couple of months then please drop me a line and I can nick the booklet in question off the BW server.

They are an excellent way to rapidly pretend to be an expert on a subject, when you are in fact a clueless Army punter.

Happy thesis writing.

The design process is laid out clearly at the start of the booklet.

The bulk of the text is a list of checks that prompt you through the design process.

Beside each checklist is a detailed explanation of what to consider at each stage.

First forays in America

Introduction

Howdy Y’all! Before coming out here Stu made me promise three things:

- Not to go native

- not to go ‘off grid’

- Not to get arrested/shot.

Because of that, I thought I’d at least try and stick to promise #2 by entering the blogosphere to provide an update on my attachment to date.

In all, getting Helen and I settled into the USA took the better part of an entire month. This was mostly spent running around trying to do things that we would otherwise take for granted in the UK but which are actually quite hard to do when you’re an alien in a foreign country. In America, you can’t do much without a social security number and a credit rating and this can complicate the already large task of setting up bank accounts, transferring a large amount of money from the UK, renting a house, buying a car, signing up for utilities and getting a phone. Most is solved by providing a very large security deposit for everything that you would normally pay by direct debit (which the US banking sector still don’t seem to have quite right…). To give a few examples, we had to pay the gas and electric supplier $300 dollars as security, COMCAST got a $150 advance for our internet, and AT&T wanted $1,000 as a security deposit for Helen and I to take out a phone contract – it was more than the cost of the handset and bundled tablet so we cancelled that transaction, opting for pay and go with a phone bought outright!). The arrivals process is also quite linear in so much as the outcome of one admin piece provides an additional proof of identity that gets you one rung higher on the ladder. Unfortunately, this means that any delays caused by an incorrectly filled out form, an absent member of staff, or freak weather event and you’re stuck treading water until you can complete that activity. Thankfully, most American institutions are surprisingly helpful and forward leaning. The process isn’t seamless (I’ve been to the Maryland Vehicle Authority twice and still haven’t finished the application for my driving license – a requirement for owning a car). Thankfully, the accent and a military ID gets you far; Helen was enrolled onto health care without a birth certificate despite it being an essential document… and I’ve only been able to get to work this last fortnight thanks to the MVA and car dealership allowing me to drive around with a set of trade plates.

…I am, however, less impressed by the embassy’s role in the arrival process who seem to hinder things more than they support…

But anyway; on to the engineering!!

The Project

Similar to earlier iterations, my attachment with the US Army Corps of Engineers (USACE) has placed me in the ‘East Campus’. This is located in Fort Meade, Maryland, which is just under an hour north of Washington, DC, and half an hour south of Helen and I’s new home in Baltimore. The East Campus “project” is actually a programme of smaller design and build projects, the focus of which currently sits with the Joint Operations Centre and its supporting infrastructure; the facility is essentially an attempt to create a “campus feel” and center of excellence attracting talent to an area that is already home to US Cyber Command, the NSA Headquarters, and a few other interesting organisations.

The main elements within the JOC project are:

- A 24/7 operation centre with “battle bridge” – Think of something akin to the Bourne series or even NASA mission control… but bigger.

- Collaboration areas / meeting rooms

- Office space

- Break rooms and canteen space

- E&M services and systems. This is going to become critical national infrastructure and pretty much everything has backups to the backup.

- IT and comms

- Security systems including everything needed to prevent surveillance such as EM and acoustic shielding (required for the structure to serve as a Sensitive Compartmented Information Facility – SCIF)

- Environmental and architectural features such as storm water management, replanted woodlands, and boulevards to create an “aesthetic open space” that earn the project LEED points (similar to BREEAM).

Where I fit in

Unfortunately, there’s not a lot I can write about yet… I have now been in the office for an entire fortnight but I’m still only part way through the bureaucracy of getting un-escorted access to the site and government IT systems. USACE is not the contractor for this project, but rather the client’s representative. As the interface between Henson Phelps (the principle contractor)and the government, USACE conduct quality assurance, investigate and respond to RFIs and administer contract changes on behalf of the clients (the ultimate owner of the site will be the NSA but different government departments are providing the funding for different elements of the project – current work is a mix of Air Force and Marine Corps).

There is also a project management element in terms of keeping an eye on the activity schedule and holding the contractor to account. By providing a pragmatic and technically-capable buffer between client and the principle contractor, I also believe USACE helps control the budget and schedule . In my two weeks here, I have already seen issues quickly resolved by USACE staff taking positions both in support of and against the principle contractor. This demonstrates a professional working relationship and makes sense. On issues where the contractor is more than likely ‘right’ or at least deserves the benefit of the doubt, USACE’s team can hasten a change in the contract and maintain momentum. At the same time, when there is doubt, the added rigor of the USACE team encourages the principle contractor to admit fault quickly and preventing unjustifiable increases to the client’s costs.

Are people in the UK or AUS seeing similar relationships, maybe with independent auditors?

My tasks thus far:

- Support to the QA team. After shadowing team members on site visits and observing their interaction with the contractors. I’ve now supervised a handful of relatively small concrete pours and a close-in inspection (prior to an internal wall having the plasterboard fitted, there is a detailed inspection of all the features inside to ensure it’s according to the specification – due to the nature of the site, this is taken very seriously). There’s an interesting dynamic that sees construction supervisors from the NSA providing a QC/QA function over sub-contractors, the principle contractor, AND USACE. It’s been interesting watching the resulting discussion when the NSA reps make demands that both the contractor and USACE disagree with… potentially a topic for a future blog post.

- Oversight of the construction of 18 small concrete footings for columns that will support cables connecting two generator farms. This is a simple job complicated by one of those farms being active and inside a separate and very restricted area of this already secure site. The task is made even more difficult thanks to the following:

– critical underground services (gas, electric and diesel) very close to the surface.

– a large open excavation adjacent to the only route in.

– the need for continued work in the generator yard (including testing and commissioning!)The contractor is avoiding the problem so USACE plan on presenting them a construction method to force them into action.

- Oversight of the construction of large numbers of bio-swales (flood attenuation and contamination control features) across the site.

- Investigation of cracked flanges in a series of “vaults”, underground chambers for electrical/mechanical works. There are a number of theories as to what might be happening ranging from subsidence of the pipes connecting them all, buoyancy of the vaults themselves, or simply damage caused by trafficking of overweight vehicles.

Hopefully, I’ll have enough for a decent blog post on the above over the next couple of weeks. I may also post some more detail on the arrivals process and the issues Helen and I have faced. The US attachment has a tradition of updating and passing down an admin instruction to those preparing to come out, however, a quick summary might be useful to those at the start of phase one or in case anybody else is assigned here in the future.

In other news.

As I can’t really upload photos from the site, I thought I’d post a picture of the new car (or at least a picture from google of the same model and colour):

If you drive really carefully and turn the A/C off she almost manages 24mpg; compared to the 50mpg in the old estate, it pretty much counteracts any savings I make from fuel being half the price! Now I just need to go out into the wilderness and justify the fact I own an SUV.

You also can’t take personal vehicles onto site so I’m also now driving these bad boys around (standby for the emergency CASEVAC to the UK once I get un-escorted access and decide to test out the off-road capabilities!):