Archive

Remedial works to shoddy piles

A quick blog on some activities I have been doing at Wentworth House Partnership (WHP). As part of my responsibilities for temporary works design for WHP I have been tasked with coming up with solutions to piling NCRs that have occurred at The Stage.

Prior to Keltbray taking over the piling contract a significant amount of piling works had been completed by a different contractor. This contractor had walked from/ been removed from the job because their methodology that they specified at tender wasn’t going to work. A large section of secant pile wall had been installed by these contractors prior to them leaving. This pile wall is to allow for the construction of a 2 storey basement. During the excavation of the basement a number of piles in the existing wall were noted to be raking into the basement area (out of tolerance for verticality), having large amounts of inclusions and/or evidence of mattressing of the pile rebar cages. These defects have been noted after 5m of excavation, a further 10m is still required.

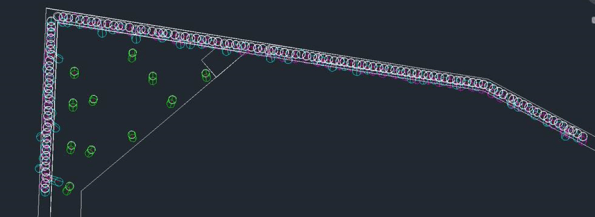

3D Modelling has been used to assess how much the raking piles were intruding into the basement footprint.

As can be seen from the image the existing secant pile wall is supposed to be installed where the white circles are. The dark green circles indicate the location of the pile at a depth of 15m. This is based on examining how far they are out of tolerance at a depth of 5m and extrapolating. A number of piles are raking significantly into the basement. These piles will have to be broken out and reinstalled. The plan for this is to break the pile out in sections and pour a concrete column to replace it. Analysis is ongoing to establish the effect of removing a pile from the wall. It will more than likely be limited to the removal of one pile at a time otherwise there is a risk of the whole wall failing.

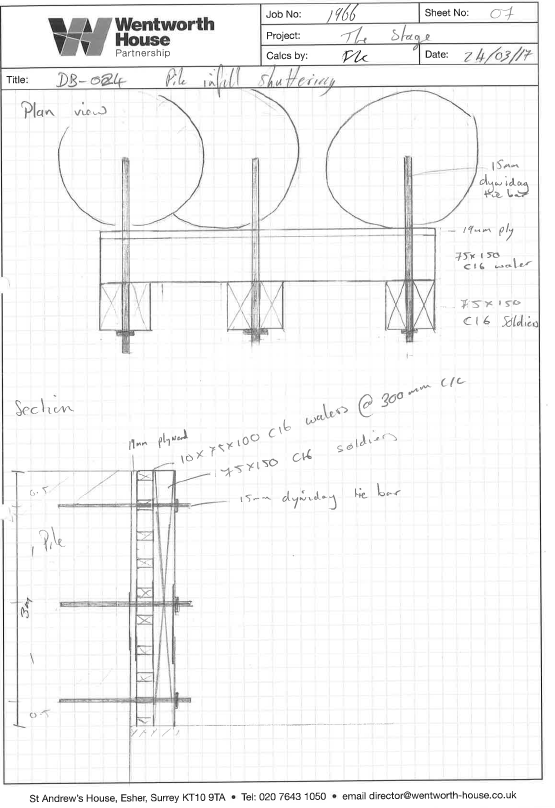

It can also be seen that a number of piles are raking away from the basement. This will result in large gaps in the wall which will allow water ingress into the basement. In this case a relatively simple formwork design has been designed in order to allow concrete to be poured into the gap. To limit the pressure on the form work I specified that the pile infill must be done in 3m high sections. This will also allow the contractors to do the infill sequentially as the excavation continues.

The above a sketch that I drew for the formwork design. This sketch was then converted into CAD by the CAD technicians so that I wasn’t giving the contractors a Freddie age 5 drawing but actually something with a whiff of respectability.