Archive

S2 Kings Cross – Orientation

I’m now several weeks into my Phase 2 placement with Carillion plc and it’s time to break my blog cherry. This post will hopefully serve to provide a quick overview of the project and company with an emphasis on pictures rather than words!

Site Orientation

The King’s Cross estate is owned by, and being developed by the King’s Cross Central Limited Partnership. One of the largest redevelopments in London, the 67-acre site has a rich history and a unique setting. What was an underused industrial area is being transformed into a new part of the city with homes, shops, offices, galleries, bars, restaurants, schools, and a university.

Kings Cross Development Area (looking West) circa 2008

The S2 site is one of seven sites that Carillion currently have within the Kings Cross Development Area. Two other contractors (Kier Group and BAM Construct) also operate sites in the development.

Kings Cross Development Site Plan (Purple-Carillion, Red-Kier, Green-BAM)

S2 project Outline

Kings Cross S2 is a new £78 million commercial office development comprising; eleven storeys of grade A commercial office development, over; retail, lobby and further office space at ground floor level, over; deep single storey basement housing plant tenant cycle storage and changing facilities and welfare. Further plant is located at levels 10 and 12 with a tenant roof terrace located at level 11. The tenant is Google UK who have signed a 17 year lease on the development. As the initial tenants numerous aspects of the build conform to their specific requirements, including double height floor spaces to various areas and open lobby spaces

Architects image of completed S2

The building frame consists of a reinforced concrete basement and ground floor, with steel frame superstructure and composite floor system. Stability is provided via a central reinforced concrete core, which is formed around passenger lifts and stairs. The cladding system is a 1.5m unitised system, with a stone faced façade. Within the superstructure of S2 there are a number of cantilever floors and setbacks. On the south-eastern corner there is a large cantilever at fourth floor level.

The substructure consists of reinforced concrete basement and ground floor with rotary bored pile foundations into London clay. Contiguous piled walls on each basement wall provide temporary retention and permanent vertical support to columns.

S2 Progress – March 2017

Contract Information

The main contract between Carillion plc and King’s Cross Central Limited Partnership is a JCT (2011) Design and Build contract with Employers Amendments. The price and payment structure of the contract is based on a lump sum with interim stage payments. The contract seems to work well on the S2 project with its provisions for collaborative working and sustainability meaning there is a real team ethos between client and contractor with a shared effort when issues are encountered. The current completion date for the contract is March 2017.

A two stage tender process was implemented for this contract. Stage one was a competitive tender aspect between Carillion and BAM, both of whom were selected off the clients selected delivery team members list. Carillion was successful at stage one and so moved forward to stage two which was a negotiated element directly between the client (Argent) and the contractor (Carillion).

Roles & Responsibilities

My current role is as the Construction Supervisor for the superstructure on the S2 project. I work directly to the Package Manager (Construction Manager) for the superstructure/substructure. Given my parameters I liaise with the other Package Managers (Fit Out, Envelope and M&E) in order to expose myself to as many activities and issues as possible. My initial time has seen my attention focused on health and safety matters and quality concerning the steel erection and composite floor construction. This period has proved challenging at times with a steep learning curve endured with regards to the project and company processes, however, this has allowed me to immerse myself in the project and understand how the project it being run.

Summary

The S2 project seems an exciting project to be involved with. I feel the timing of the attachment has been well situated in terms of the project programme with a vast amount of activity currently being witnessed with numerous trades all working on site. As with probably all students my concern at this early stage is that I will be able to meet all the ICE Attributes in the time available.

I hope this post has been partly interesting in setting the scene. I will look to provide some site related engineering issues in the near future!

Sustainability through Design

Conscious that CPR is just around the corner and Sustainability still looks to me like a vague, tree hugging engineering attribute, I have volunteered to join the Robert Bird sustainability working group. Made up of engineers from varying disciplines (Geo, Temp Works, Civil’s and Structures) and experience depth/seniority, our objective is to develop a sustainability approach within RBG and provide focused support to ongoing projects.

In today’s meeting a senior project director asked us to look into a very specific client request to try understand the risks and opportunities from a sustainability perspective. In broad terms, the local planning department and client have mandated that 25% of all aggregate used in his project must be reclaimed. Though we have a 40 storey concrete residential structure in which we could potentially hide this high percentage of reclaimed aggregate, unfortunately the structural engineers have told us they do not want to use it in any columns or beams because they are concerned about its performance.

The interesting thing about this mandated condition is that we have no context to its origin or underlying intent. By that I mean we have no idea what the planning department aims to achieve by it or if it was just a random number plucked out the air by a Planning Department work experience undergrad ? Most of the team assumed it’s to reduce the carbon cost of the project. Someone thought it is intended to reduce the number of vehicles transported to site and one engineer suggested it is simply to save cost. At this point we don’t know.

Has anyone else encountered this requirement before and have any views on its impact?

We are now researching the following basic angles to increase our understanding of the options open to us.

- What is the key incentive for this planning constraint?

- If it’s to reduce the Carbon cost and we can’t get 25% reclaimed agg into the design, can we offset this shortfall with other C02 saving methods: ie use of GGBS or other cement replacement products?

- What are the structural issues with using Reclaimed Aggregate and how does it affect performance?

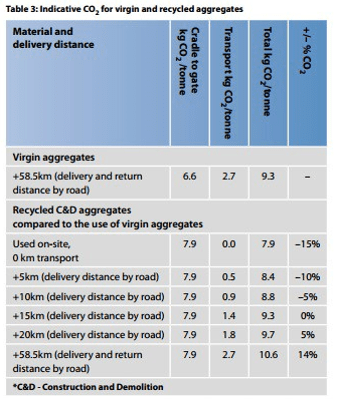

- At what point does using reclaimed aggregate actually add to the Carbon cost and are there suitable suppliers within range of task site? The following image shows that as the distance of transport to site exceeds 15km, the carbon saving is eradicated.

Anyone got any thoughts or experience of this stuff? In the meantime I’ll be chained to a tree at an anti fracking protest whilst waiting for answers.

Cheers

TD