Static mechanical update

This is just a quick update since my last post on the projects that I have been delivering.

Hydraulic fracturing hanger – static mechanical

This project was the main focus of my last post and is nearing offshore construction. We managed to reach all the construction deliverables, a fairly simple task since it is a single discipline, static mechanical project. This was key since the asset can turnaround and refuse your construction window based upon readiness of the task. I’ve included a couple of photos below to show the location of the hanger in relation to the asset. If you look closely into the yellow box you will see the thredders bloke who has to escort the drone pilot around.

The key issues associated with offshore construction will be the removal of the heavily corroded bumper bar, contingency is the use of hydraulic jacks to persuade out of the sleeves. I’m currently luckily enough to mobilise for the days leading up to the construction but because of flights cannot stay on the platform. The offshore single point of accountability, during the construction phase, falls to the Maintenance Team Leader with daily VCs with onshore to update on progress and issues. This is particularly difficult since, unlike most of you, I cannot nip outside to go and see the problem.

Clair Low Temperature Modifications

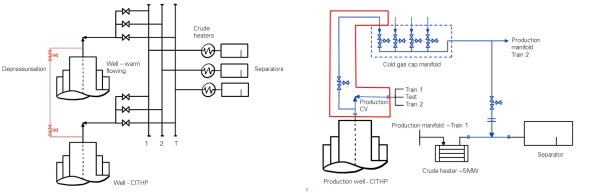

I’ve recently kicked of a new project which involves the installation of low temperature rated pipework to depressurise the wellhead following a period of shut-in. When the well is shut-in, for emergency or maintenance reasons, a gas cap forms a Closed in Tube Head Pressure (CITHP) of around 160bar (bad). If you were to depressurise this in the existing pipework the temperature would reduce to around -70degC (bad) and cause low temperature embrittlement (bad). The temporary solution, shown on the left below, was to depressurise this through flexible hoses into a known warm flowing well. This practise, while functional, was deemed unsuitable due to the requirement to break primary containment. It also took around 5 days to complete. The permanent solution, shown below on the right in blue, is to install low temperature rated pipework to depressurise, through a manifold connected to all wells, into a warm fluid downstream of the crude heater. Phase 1 of this project was completed in 2015 with Phase 2, my project, installing the pipework to tie-in 4 wells into the cold gas cap manifold. Complexities include construction priority vs asset priority, securing dates in the asset plan, while working up the engineering in a relatively short time frame.

Discipline Engineering – blast analysis

Unlike other phase 2/3 attachments, there is an opportunity at BP to conduct the phase 3 element alongside phase 2 work. As such I’ve recently started a piece of work which is to answer a technical query raised by Wood Group. This TQ queried the levels of blast, if any, which should be used when designing the new flowlines of recently drilled wells. A comparative study was conducted by Frazer-Nash which compared the methods used by 3 popular contractors used by BP. This study highlighted the lack of standardisation through interpretation of the design guidance. Frazer-Nash have subsequently conducted their own blast analysis of high risk areas of the platform which resulted in all elements of the flowlines and supports failing in both elastic and plastic tests.

My job now is to interpret the results, linking this to the Quantitative Risk Assessment, to decide what the effect of not design/designing for blast and to what level it should be accounted for. I don’t know anything about blast.

Note: Static mechanical was the term used by a structural engineer when describing his job. I think it’s an in joke.

Thanks for an interesting update.

Static mechanical……….