Archive

Reactive Dewatering

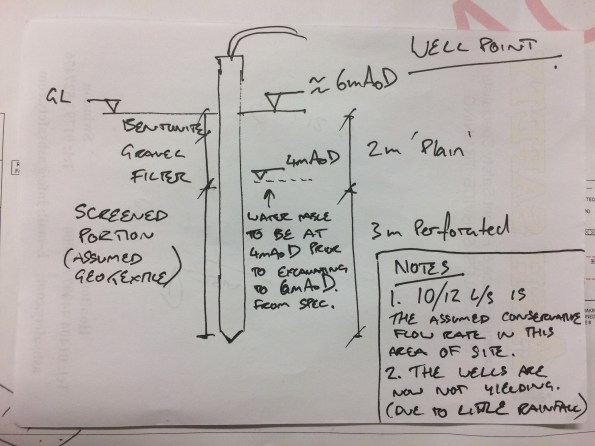

The excavation in which I am working is affected quickly by rainfall and subsequent water ingress. These wellpoints were installed as a reactive measure to lower the GWT prior to excavating to formation – the level pictured. They were only installed circa 10days ago. Does anyone know if the Corps have dewatering capability? The wells are connected to a Sykes portable pump then into a tank. Groundwater is separated from run-off (which is collected in sumps) due to potential for contamination.

10-12 l/s is for slightly deeper wellpoints, therefore sub 10l/s is more likely.

Game of Standards

Tasked to investigate a potential cross-contamination issue within a number of disabled en-suite bathrooms, this post aims to articulate some of the issues that I came across.

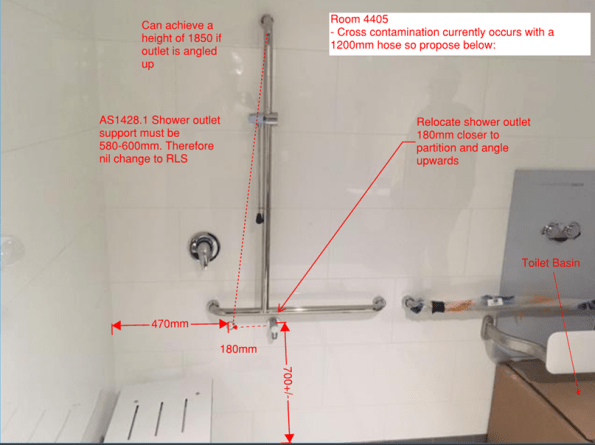

Task Overview. During a scheduled visit by the Client (New South Wales (NSW) Health Care) of the Acute Services Building (ASB), it was minuted that a shower hose within one of the disabled en-suite bathrooms had the potential to make contact with the toilet basin – a cross-contamination issue. My initial task was to support a Graduate Engineer to investigate this claim.

Response to the Task. My first action was to establish the facts; what Australian Standard (AS) must installed shower hoses comply with? The Standard, AS1428.1-2009 Part 1 (Design for Access and Mobility), stipulates “that the base of the shower rail should be 700 mm above the floor, with a minimum of 1500 mm hose length”; dimensions sufficient enough for a patient to grab the hose or for a carer to wash an individual.

I then discussed the issue with the Subcontractor responsible for its installation. Of interest, and not surprisingly, the Subcontractor’s representative attempted to reassure me “that all was well” with the installations. I was not content with this level ‘assurance’ and conducted a full inspection of all 24 disabled bathrooms; 6 were confirmed as having shower hoses which could make contact with a toilet basin. (The shortest hose length to avoid contamination would have to be 1200 mm, 300 mm below the AS.)

Unable to recommend the use of a smaller hose length at this stage, and to avoid raising an unnecessary variation, I arranged a User Group meeting to establish ownership of the risk and present a solution. My initial recommendation to the Client, confident that AS 1428.1-2009 Part 1 would suffice as justification, was to implement addition disinfection measures into daily working practices to mitigate the risk of any contamination spreading. This was rebuked with another Standard, AS 3500.1:2015 Part 1 (Water Services), by the Client’s representative, which claims that “any cross-contamination potential must be mitigated”.

Mistake made: Not widening my understanding of associated Australian Standards.

The Regain. Unable to resolve the associated risk due to this AS “deadlock”, and with a young graduate stumped for options, I seized the initiative to seek advice from the Building Codes of Australia. Now furnished with an understanding of the Disability Discrimination Act (DDA) 1992, drawing attention to “it is against the law for public places to be inaccessible to people with a disability” (Australian Human Rights Commission, 2017), delineation of AS was achieved by the interpretation of a clause that states “to comply with the DDA existing places may need to be modified to be accessible, except where this would involve unjustifiable hardship”; AS 3500.1:2015 had won the argument.

Acting on this information, I drafted a preliminary design that minimised “unjustifiable hardship” while mitigating the risk of cross-contamination; better to inconvenience the User rather than raise the risk cross-contamination across several areas of a hospital. My recommendation, illustrated below, includes relocating the shower hose rail further away from toilet basin and shortening the hose length below 1200 mm. This recommendation was upheld by MPX and the Client. A variation was then raised and a Site Instruction issued in order to complete the works.

A Quest for Answers. Understanding that one can’t foresee everything, and curious by nature, I then researched if a similar experience occurred elsewhere. It had, and in Australia! An article in the Master Plumber, Western Australia discusses that AS 1428.1-2009 is “continually being debated by installers, designers and compliance officers throughout Australia”. However, it did not provide any substantial root cause solution.

Still intrigued to find the root-cause, further investigation points towards an error by MPX’s architects. In short, they have not designed all of the disabled en-suite bathrooms large enough, despite issuing “For Construction” drawings to the Subcontractors!

Until to next time…