Home

> Uncategorized > Reactive Dewatering

Reactive Dewatering

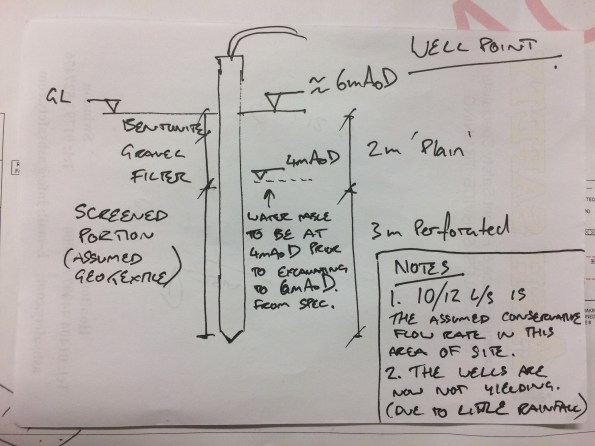

The excavation in which I am working is affected quickly by rainfall and subsequent water ingress. These wellpoints were installed as a reactive measure to lower the GWT prior to excavating to formation – the level pictured. They were only installed circa 10days ago. Does anyone know if the Corps have dewatering capability? The wells are connected to a Sykes portable pump then into a tank. Groundwater is separated from run-off (which is collected in sumps) due to potential for contamination.

10-12 l/s is for slightly deeper wellpoints, therefore sub 10l/s is more likely.

Categories: Uncategorized

Dan – I don’t think that the Corps has any such capability. These spears look like they might have been introduced by flush boring – that is using high pressure water jets at the end to advance then to position.

There would have then been some well development to improve the hydraulic connectivity between the ground and the well point

What is interesting is that the headermain ( the pipe connecting the spears) look really small so that the implied dewatering flows must be down at 10l/s or so….. any further information?

John – I will get a hold of some info. It is connected to a tank so should be able to give you an idea of rate, most have flow gauges on them but these do not. Having observed the pipes yesterday flowing there has been air visible when the pipe was flowing suggesting lower flows or at least less than the pipe was capable of.

Most of the drilling of nails uses compressed air flush and top hammer rigs. but having seen permanent stainless steel wells bored for the reactor dewatering I agree with your suggestion of water flush. I’ll confirm with the drillers in the morning.

It was a compressed air flush using a top hammer rig. There was a small submersible placed in the bottom.

The wells have reduced the water table, the residual flows are now being contained by sump pumps prior to dealing with 100mm layer 1 blinding tomorrow (somebody forgot to order the concrete for the pour yesterday).