Alway interrogate loads!

I am currently working through packaging up the loads from the Tower Cranes, which connect to the permanent structure by a steel grillage. These loads will then be checked against pile capacities. I have been embarrassed slightly but it has taught me a valuable lesson which I will explain below.

The Tower Crane strategy on a high rise structure is a key element to a tender, the number and location is picked before sub contractors are brought on board. The tendering of packages is then conducted on this number, location and a % time allocation and are therefore relatively fixed.

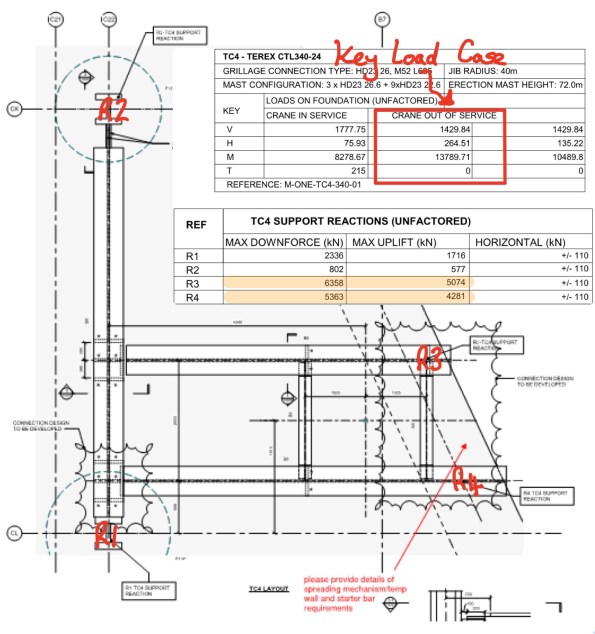

In order to be confident that the locations are feasible, MPX contracted Robert Bird Group to conduct a feasibility study which suggested a steel grillage would work in the configuration below for one of the tower cranes.

Once the basement subcontractor had been appointed (on a PCSA), they took the loads from the Crane supplier and sized the steel grillage. Now, if you imagine a 70m high free standing column, the horizontal load from wind will create a significant overturning moment. This moment along with the self weight creates large tension and compresive forces in the legs of the crane. This results in large reaction forces in the grillage supports (in this case plunge columns in piles and a diaphragm wall) and due to strict movement criteria the grillage is fabricated out of deep I Beams (large second moment of area).

The plunge columns and piles have lots of spare capacity, provided the detail of the connection doesn’t create a load at an eccentricity and hence large moment. The D Wall however has very little spare capacity, I suspect this is because the designer has been very conservative due to the presence of a scour feature. Anyway when I went to the designer and said MPX want to put almost 13MN in two point loads on the D Wall he laughed in my face and said it’s not possible….. Que lots of head scratching by most of the MPX Engineers, calls to various people to move cranes, reduce sizes and extra piles flying in everywhere.

The plunge columns and piles have lots of spare capacity, provided the detail of the connection doesn’t create a load at an eccentricity and hence large moment. The D Wall however has very little spare capacity, I suspect this is because the designer has been very conservative due to the presence of a scour feature. Anyway when I went to the designer and said MPX want to put almost 13MN in two point loads on the D Wall he laughed in my face and said it’s not possible….. Que lots of head scratching by most of the MPX Engineers, calls to various people to move cranes, reduce sizes and extra piles flying in everywhere.

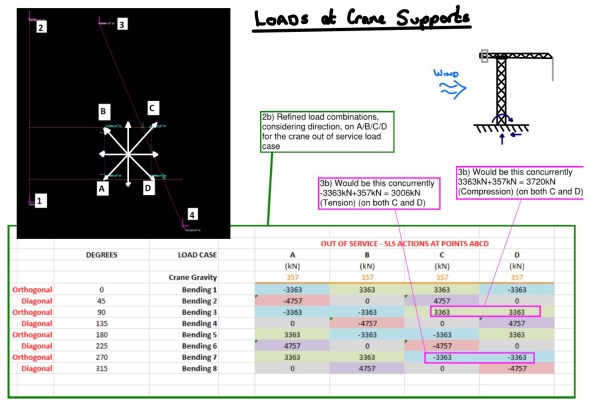

Anyway after a day of flapping and the drafting of a few concept ideas, a small structural firm called BG and E where emailed the concepts to have a look at. The Senior Engineer referred to the guy as an absolute ‘gun’, I assume he means he is your top third engineer. We went over for a coffee and a discussion, the first thing he said was “look at your load case, from the load envelope, Carey’s have provided the max and min for all reactions”. And here the penny dropped, its impossible to have max reaction on the D Wall at the same time, instead of text I have illustrated this below.

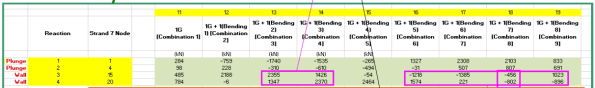

By considering the load envolpe properly the loads on the D Wall have dropped by 60% (combination 3 and 4 below), it will still be tight with the vertical capacity but potentially workable. I suppose in the long winded blog I am trying to say, always interagete loads given to you by another engineer before you plow on and use them, it saves embarrassing moments.

Brad, dumbing it down for my benefit, what was the make up of your original load (the big one)? Did it include two things that couldn’t exist at the same time? That’s what I understand from your post.

Wind load creates a monent at the base of the crane, this is large, the crane is a 70m column fixed at the base (second drawing big red box). The moment is resisted by reactions in the crane base (see A, B, C, D on the third drawing), the white arrows represent a moment from wind in a direction, for this analysis it has only be considered every 45 degrees. Looking at the table title out of service loads, the max at C and D (4757kN) is when the moment is considered at 45 and 135 degrees, due to the layout of the grillage this gives the max reactions R3 and R4 (6358kN and 5363kN) but wind cannot come from two directions at the same time. The worst load case for load on the D Wall is the moment considered at 90 and 270 degrees, however because both tension and compressive loads occur on the grillage in close proximity the total load on the D Wall is much less, see the final table with max reactions highlighted in boxes. This clearer? Maybe I haven’t explained it well but I tried to limit the words so people will read it. In short always consider the loads and if load combinations sensibly act together.

Post was spot on mate, it was my brain that was the bother. Thanks for explaining it – got it now.

Brad, interesting that existence of tension and compression in the crane base decreases the reaction at D. Why do they only consider the out of service conditions for analysis? What wind speed do they assume and what’s the operational wind speed limit?

In this case it is because of the geometry of the grillage, it’s not true in all cases. The out of service load case is the critical due to the large moment, a quick hand check confirms this, i.e. By comparing the moments/span between crane legs + V/4 for the three cases.

I’m in the Alps at the moment so don’t have this to hand. Interestingly TEREX who provide the unfactored loads have built in a FOS (which the do not disclose), this came to light as the connection bolts failed the design check. When it was quieted the answer came back not to worry. This ‘built in’ FOS compounds the strict movement criteria resulting in a overdesign grillage and connections. But I suppose it’s there to save the crane driver and others from idiots like me. I hope the tan is coming on well.

Brad,

Will the crane be tied into the building at any points (looks like there are some on the diagram)? This would reduce the 70m free standing worst case scenario. If so, there can be some interesting overlap between permanent and temporary works at the tie in points. There might be some useful thoughts on programme based on crane rises as these normally stop work a for a period.

Are any train lines within a potential fall line of the crane? Network rail have very particular approvals processes for cranes if you are.

Damo

Hi Damo,

It will be, the the crane will be erected to 70m and tied in as the superstructure increase. So moment overturning moment will reduce but the load from the structure will increase, this is all supported on plunge columns which the get incased an the effective length reduced with the casting of basement slabs.

The 70m high without ties was picked in order to reduce the number of required jumps as the crews are difficult to book and everybody wants them at weekends. A superstructure contractor is yet to be appointed so at present the ties go to temporary columns but there is little detail bar a sketch.