Archive

Always Interrogate Loads Part Two!

After Brads post last week I thought I’d jump on the bandwagon and descried a similar load related situation we unraveled last week.

The D-Wall for the Station Box at Battersea was installed last year and contains a number of plunge columns. When installed one of these plunge columns was put in 40mm horizontally mis-aligned, and at an angle amounting to circa 100mm out at depth, then to cap it off the concrete for that D-Wall section was thought to have been poured low.

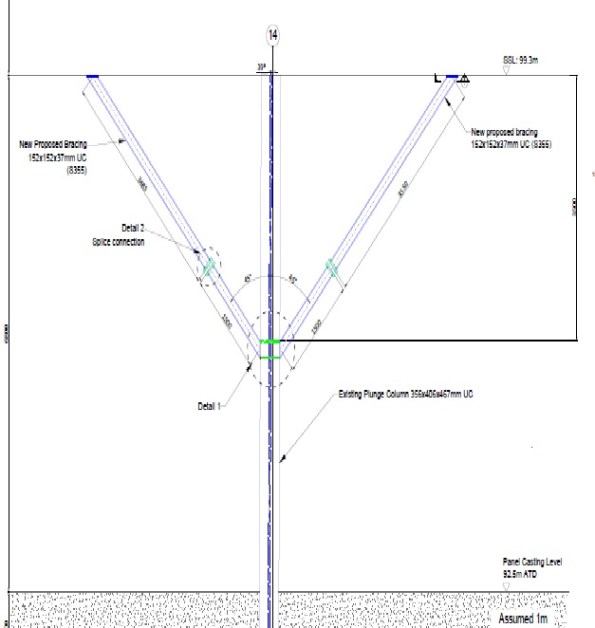

This results in a design for temporary bracing, to be installed to reduce the effective length during the temporary construction stages.

Everyone on site knew this bracing needed to be installed but no one had really questioned why and if there was another method to brace the column. I initially put forward two suggestions:

- Brace the column from the permanent works below, thereby reducing the requirement to lift the UC bracing sections and drill and fix into a soffit at height.

- Why couldn’t we just cast the RC encasement now?

Although I quickly disproved my own ideas it led me to look at the calculations, and the design behind the bracing. It turned out that the column failed in the buckling check by 118%. However the load case on the column included a temporary road/platform which no longer was going to be constructed. This temporary road added 1300kN to the axial load of the column therefore once this axial load was deducted, the column passed the buckling check and the bracing was no longer required. This was subsequently agreed by our TW cell and the Designers.

From a H&S point of view this eliminated the need to conduct a difficult lift inside an excavation, drill and fix into a soffit at height and the construction of temporary works. In addition it saved time off the programme. All this work was going to be conducted because no one had thought to question what we were doing and interrogate the designed for load case for the column.