Transition to the USACE Design Office at 2 Hopkins Plaza

With the cobwebs of Christmas and New Year finally gone (along with AER 4) I thought it was about time I wrote an update of my attachment in the USA.

As of mid-December, I was able to handover the majority of my work at the East Campus in Fort Meade to a young and overly energetic intern. With the majority of the project complete and the main effort shifted to the architectural team’s handover of internal rooms and the mechanical team’s underfloor air distribution (UFAD) testing and commissioning, I almost felt a little sorry for the guy – arriving with so little civil works left to complete. From me, he inherited responsibility for:

- Processing and distributing the daily submittals from the contractor,

- Supervising the production of as-built data for the site’s sustainable storm water management (SWM) systems.

- Supervising the placement of internal roads (a combination of pervious, and impervious concrete), and

- Supervising the contractor’s application of erosion and sediment controls on behalf of the State’s department of the environment.

Surprisingly, he seemed a little overwhelmed and concerned that some of the work allowed him to make decisions and issue site instructions. I hadn’t realised how accustomed the army and such a short time spent on Phase 2 had made me to making decisions and accepting responsibility. In his defence, I suppose he hadn’t even been qualified for a year and speaking to him later, it became apparent that USACE severely warns them against obligating the government to anything not already in a contract (for those just finishing up on Phase 1, remember this and don’t be overly critical of yourself when it comes to judging attribute competences).

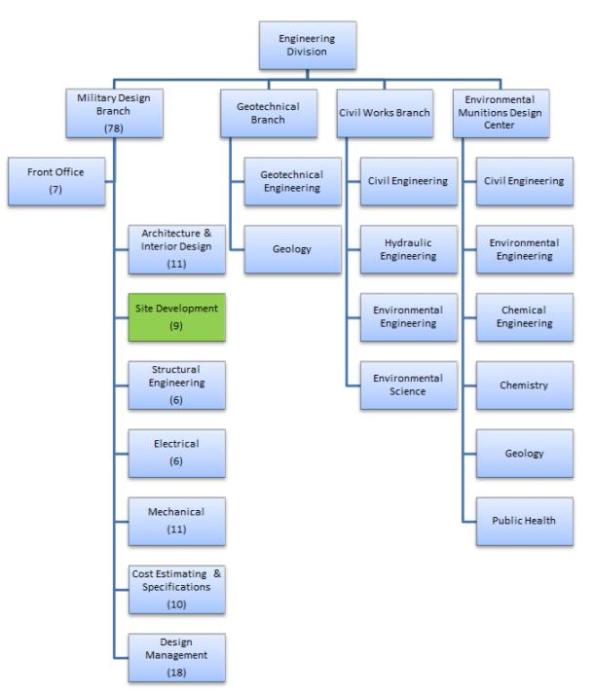

Closer to the present, January in Baltimore has been an intense combination of very, very, very cold weather and also my re-introduction to technical engineering. After a full 8 months of performing QA of “horizontal construction” (drainage and grading, pavements and slab-on-grade with a little bit of footing work), I have commenced Phase 3 by assuming a design engineer role in Baltimore City. From now until the end of June, the intent is to work within the USACE Site Development Section performing a broad range of infrastructure and site design tasks. A small hierarchy made for AER4 showing my location within what is effectively USACE’s Baltimore design office is shown below:

The parent organisation of the site development section is the Military Design Branch. These approx. 80 personnel design and supervise the construction of DoD facilities across an area of responsibility approximately similar in size to England and Wales. This work includes “in-house” design for DoD organisations and the technical review of in-progress or completed Architect/Engineer designs by third parties.

My main role includes a number of small tasks that essentially see me designing sustainable drainage solutions for DoD installations. The scale varies from designing systems to manage surface water volumes from design storms (normally the 1 in 2 and the 1 in 100 year storms) to designing retrofits that ensure pollutant loads such as Nitrogen, Phosphorous, and total suspended solids are reduced in the “first flush” of 1.0 inches of rainfall.

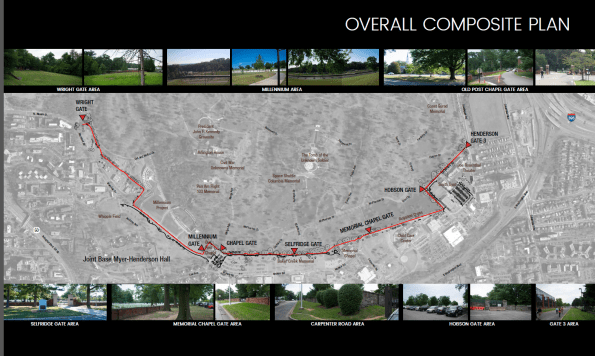

I will also soon be designing stormwater management aspects of a 2km perimeter fence that is going to be installed in Ft Myers, not far from DC and the Pentagon. Strangely for the US military, a large section of the perimeter since the late 19th century has been a 4-ft high stone wall. A number of recent incidents have occurred involving French tourists getting lost in the neighbouring Arlington National Cemetary and ‘hopping the wall’ to get to what they think is a nearby strip-mall. Unsurprisingly, the DoD has decided it may be time to increase the level of security. In addition to designing the profile and construction details of the fence plus integrated cameras etc… the project also requires consideration of bisecting drainage channels, the construction of a new car park and creation of additional SWM to account for the increase in impervious surface areas.

As we’re still waiting for the client to decide on the contract vehicle for this work, USACE and I are still a little unsure on the level of design work required but we hope to get an answer fairly soon. Until then, here are some unclassified graphics pilfered (with permission) from the department’s project folder (yes, that is a design engineer’s attempt at doing before and after concept work using photo-shop):