Archive

Temporary Works

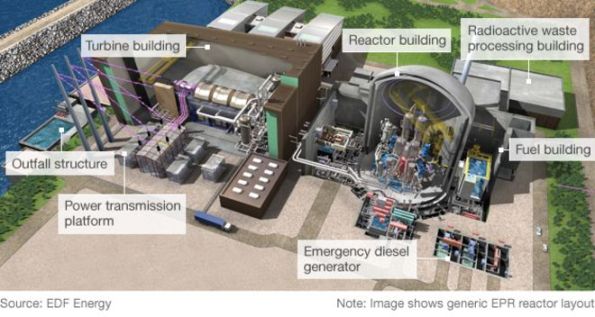

I am working in a team of 10 for the JV that has the main civils contract for Hinkley Point C. Bouygues-Laing O’Rourke (Bylor) are responsible for the structure(s) that contain the nuclear gubbins for the 3200 MWe reactors, cooling systems, and ancillary buildings. Currently circa. £2bn of contracted scope, and rising.

The TW office responds to requests for scaffold, formwork, lifting calculations and other curios from site on an ad-hoc basis. They liaise in advance with the pre-construction team (working mostly out of Paris) to design formwork and falsework systems along with bases for the 40-50 tower cranes to be installed. Large volume packages are let and managed by the TW team to supply chain companies like Sateco, Peri, Doka and Hunnebeck.

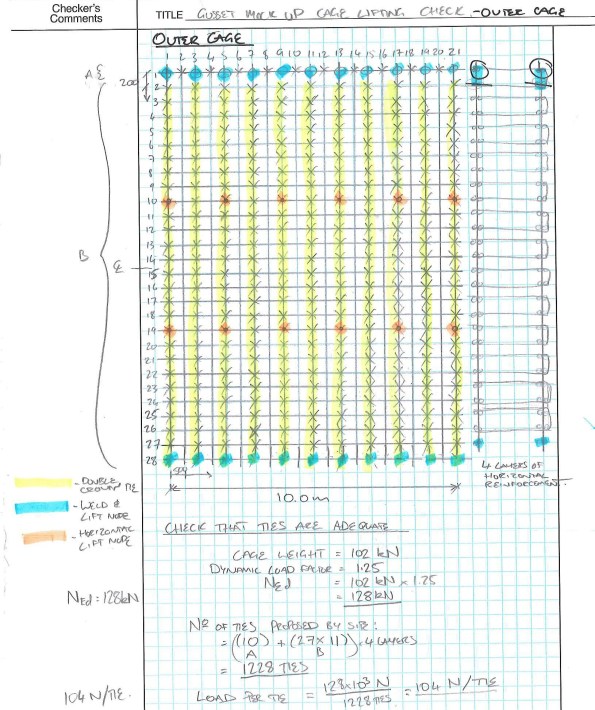

I just completed my first task which was re-working some calculations for reinforcement cage lifting and issuing the new lift schedule to site. Not quite a flume I know Ed! The cages were for the reactor inner containment structure which consists of a pre-stressed ring and conventional reinforced concrete. This forms the lower wall of the reactor building(s). I can’t put up any decent drawings or models, unfortunately. The re-working was required as the method of installation changed, separating the cages into smaller lifts.

I was surprised at the factor of safety of 1.35 x 1.2 was applied for what is 3 crane lifts. Onto the wagon, off the wagon and turned vertically prior to installation. By using some steel designers manual/StaadPro/standard beam formula I managed to reduce quite a lot of the welding on each cage. The number of ties on the cage was the critical case.

Proposed tie and weld arrangement. Still less conservative than the original design.

Ties themselves are difficult to quantify although tensile testing exists. An assumed SWL of 254N (25kg) gave a FoS of 8 from tensile test results. I couldn’t find out where that SWL was taken from. It seems rightly high in FoS terms given the risk of corrosion, human error in tying and damage. Future testing of tied wire is in the offing which should provide data for my TMR on the subject. I expect the variance between samples to be greater, and still quite difficult to pin down. However, any improvement in capacity reduces the amount of work for the steel fixers which equals fewer hunchbacks and less knackered wrists!

Working in the office is a noticeable step change from the site. Namely, that, a lot of people wear headphones all day and there are fewer threats of violence or general harassment. When I told the animals on site that I was going to work in TW they said that I’d be responsible for adding zeros to the budget and making things difficult to construct. On reviewing a small work package for welding to reinforcing cages I have observed how this can occur. I have also seen how easy it is to specify something that is overdesigned or even unsafe to construct. Particularly as they do not see many pairs of eyes before heading out the door.

I’ll hopefully have something more coherent and of note to post soon.

Dan