Archive

Time spent on resin is rarely wasted..

This blog is mainly aimed at my fellow phase 2 students and will probably appear obvious to the more experienced readers. However, I thought I would share a quick post about the amount of construction time that could be saved by challenging the detailing the design team annotate on drawings.

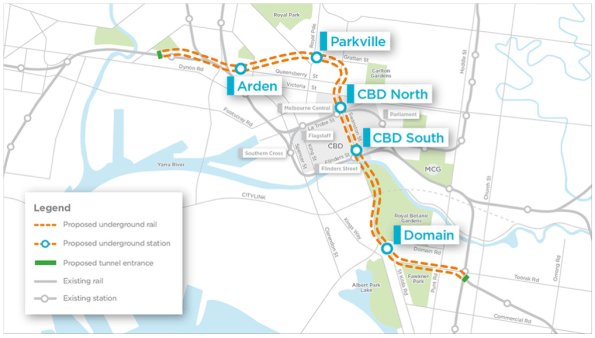

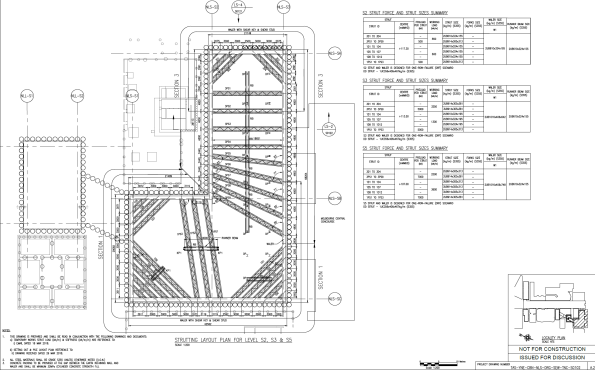

Firstly, as I have not yet blogged about my project, a quick introduction is required. I am working on the metro extension project in Melbourne, which is being undertaken as a joint venture by John Holland, Lendlease and Bouyges Construction under the contractor name Cross Yarra Partnership (CYP). In short, over the next 6 years the project will deliver two twin 9km tunnels and 5 new underground stations, with multiple entrances, within the Central Business District (CBD) and close suburbs (figures 1 and 2). The project is at the very beginning of construction and I am working within the CBD shafts team, delivering the 8 CBD station boxes that will allow access for underground mining operations and form the outer perimeter for the permanent station boxes (for the civils, think a more complex version of EX COFFERDAM). My current responsibilities are aligned to the design, procurement, installation and quality management of the temporary strut support system for each of the 8 CBD excavations, for which, the design and supply sub-contract has been awarded to Yongnam Steel (based in Singapore). Figure 3 shows a typical plan view of the strut layout.

Figure 1 – Metro extension alignment

Figure 1 – Metro extension alignment

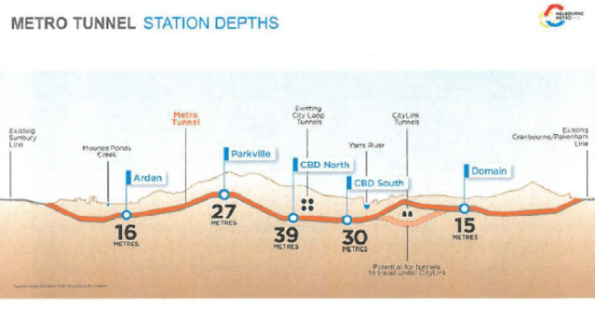

Figure 2 – Metro extension station depths

Figure 2 – Metro extension station depths

Figure 3 – Typical strut layout

Figure 3 – Typical strut layout

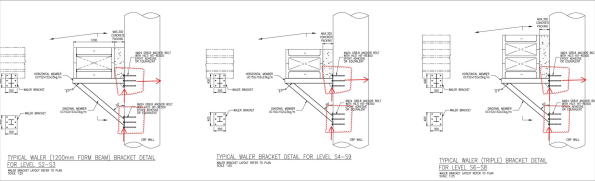

So, into the meat of the issue. I was asked this week to investigate ways in which the installation timeline could be ‘rationalised’ to try and gain some time back on one of the excavations. Feedback given by the team working on site identified that the critical path for the installation of the waler and strut at each level was aligned to the amount of time the resin, for the bolts holding the waler support bracket, took to cure before loading (Min tcure). On the design drawings (figure 4) supplied by Yongnam, the detail stated that the epoxy adhesive should be Hilti HIT-RE500 or equivalent. As detailed on figure 4, this instruction is the same detail for each of the levels of struts, even though the waler and strut size at levels S6-S8 is much larger than the upper levels. The selection of the resin is based on the calculated shear and tension at the bracket location. The installation team suggested that this is most likely a standard detail on the upper levels, basically, to meet design timelines Yongnam will have designed for worst case shear and tension and then applied this across all levels. In terms of time, the minimum curing time for HIT RE-500 is 16hrs, which means the installation process is split across multiple 8 hr construction shifts. Whereas, for lower calculated shears and tensions, HILTI have other products such as HIT-HYH 200-R which cuts the tcure down to 2.5hrs, enabling more construction to take place within the 8hr shift and speeding up the overall installation process. There is also a combination of bolt size and resin selection that can be achieved to optimise tcure for each level of struts, dependent on the calculated shear and tension.

Figure 4 – Waler bracket detail

Figure 4 – Waler bracket detail

The RFI has been sent back to Yongnam to confirm the shear and tension at each plate location, so we can rationalise the selection of the bolt and the resin selection at each strut level. This detailing is something that I had never really considered could have such an impact on a project timeline, especially such a big influence on the critical path. This may be of some use to other phase 2’ers being asked to rationalise their own construction timelines. I will update the blog in the comments when I get the feedback from Yongnam and the final calculation of time saved is completed. Thoughts welcome on any other tips and tricks for cutting this time down?