Batter… that’s something you put on fish right?

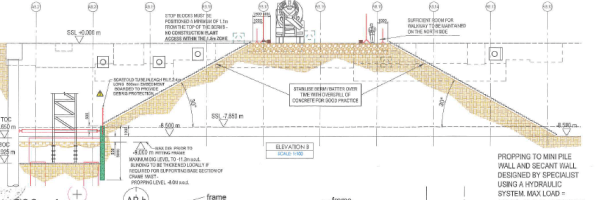

I’m working on Phase 2 of the Battersea Power Station Development Project (the actual power station bit). This post is related to Heath and safety on site. On the surface of it they appear incredibly H&S conscious, with a site flooded with orange jacketed traffic marshals and slinger-signallers and the logo “safety first, second nature” plastered everywhere. However, with a bit of digging below the surface (quite literally) they don’t seem to be quite as worried about the slightly less obvious but potentially incredibly dangerous situations. This lack of safety manifests itself in two ways; 1) constantly putting workers down deep excavations without any attempt at slope stabilization and 2) loading the top of steeply battered slopes. The second of these situations is the one I’ll go into detail on.

The situation shown below grabbed my attention on site because the slope batter looked to be at an angle that is too steep to support construction plant so close to the edge. I mentioned this to the supervisor and construction manager on site, who were not worried, believing that 45 degrees was an “ok” batter (I think that 45 deg is generous). Recalling that the thi dash/2 plus 45 rule goes out of the window when loaded, I was not sure about this, so checked it with some analysis on Geo5.

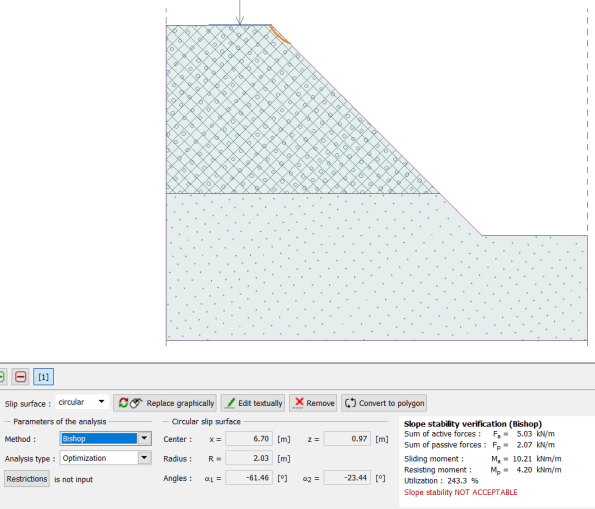

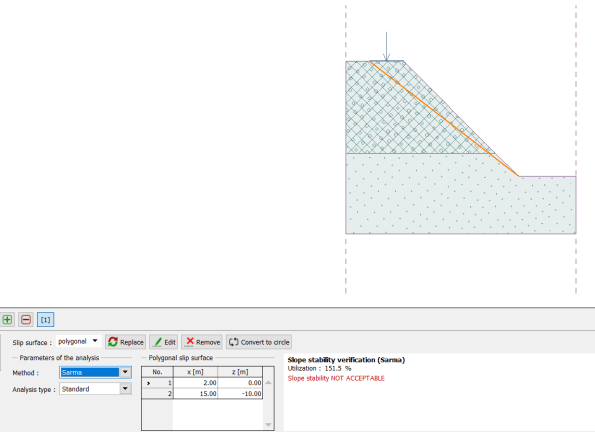

Some quick calculations on Geo5 using the information obtained from the Ground Investigation Report show an unstable slope.

Some quick calculations on Geo5 using the information obtained from the Ground Investigation Report show an unstable slope.

Load (mass 23000kg) = 226 kN

Modelled as a distributed load over the area of the excavator.

The ground profile is not certain, due to the possible presence of a scour feature. I have taken the case as being in the Short term, as the excavation is only to be at this angle for a couple of days. So the worst case is with granular made ground from 0 to -8, and scour infill from -8 to -15.

After some more digging (i’m sure this pun has been done 100 times before on this blog but it’s worth getting it in), I also found the Risk Assessment/ Method Statement, which states that the safe batter is 30 degrees, and that stop blocks should be positioned a minimum of 1.1 m from the edge. I informed my supervisor, who is also the senior project manager in charge of ground works, who said that he would look into it. They have since carried out a deeper excavation on a steeper slope elsewhere. 🙂

Hi Ed, good blog. Most of us working in the mud have seen exactly this. I think Henry M did a blog on something similar.

The iPhone has a angle thing which is useful for onsite checks.

Something else to consider. In the picture you show where the plant is excavating with the arm extended. The pressure under the two tracks is much higher at the front. At some point it with do 180 with a full bucket moveing the higher pressure to the rear and further from the edge.

I suspect this is sensitive to how large and how close it is to the edge.

Oh it would also be great if you could jack up an inform visit, I would be interested in having a look around.

Here’s a thought Ed

You didn’t really critique the ‘designed’ batter at 30 degrees.

It may be that the reason that the advice has ignored was because it was not a design at all; rather a lazy ultra-safe number without much thought applied.

This has two important outcomes:

a) the cost and time required for the solution proposed places a burden on the project that it is possible for any foot to query;

b) worse; that any fool then decides on an equally stupid guess at a safe slope and moves the project forward to the sponsors benefit but , in doing so, are ignorant of implied unacceptable risk.

The out-turn is a view of engineers that many PMs hold and that is that ‘ all they do is cost us too much money’.

So the original design was as much to be held in disregard as the site base ‘guess’

The issue here looks to be the influence of c’ . I applaud yout recall of 45 plus phi’/2 but this is in the context of the fact that, because of the difficulty in establishing C’, in a military context, we disregard it.

If you put modest values of c’ into your analysis you will see that you can achieve high safe slopes.

Also buried in 2.4.7.1 pf BS EN 1997-1 is the following:

Less severe values (this relates to partial safety factors using in limit state analysis) than those recommended in Annex A may be used for temporary

structures or transient design situations, where the likely consequences justify it.

These can be applied in GEO5 because you can define gamma’s for your analysis early on

There is a discussion of this ins PAS 8812:’Temporary Works – Application of European Standards in design: 2016 (Brad, this was the code advice I was discussing with you)

You might ask yourself; how you could have designed this in the first place to win the confidence of other team members? Because if all we’re ever seen as is harbingers of doom …then we deserve the actual or implied opprobrium we receive.

A TMR at least I’d say?

Told you you’d get comments! Question is how granular is granular fill when it has a fine grained component. It’s a good observation and one worth working through because the result has implications for workers in open, unsupported excavations and the concept of stability in the temporary state.