Archive

Click here to confirm your consent to continued emails on our mailing list…. What is GDPR and does it affect us as engineers?

If you are like me, then you have noticed a barrage of emails from all the obscure companies and websites that you may (or may not) have signed up to since, well, ever. The reason for this surge in correspondence is the EU General Data Protection Regulations (GDPR). The new rules take effect from today, updating and standardizing data protection laws across Europe, including the old UK Data Protection Act of 1998.

If you are like me, then you have noticed a barrage of emails from all the obscure companies and websites that you may (or may not) have signed up to since, well, ever. The reason for this surge in correspondence is the EU General Data Protection Regulations (GDPR). The new rules take effect from today, updating and standardizing data protection laws across Europe, including the old UK Data Protection Act of 1998.

Being in the US, I’ve managed to avoid the majority of the news and all the effort involved in preparing for GDPR but now that I’m getting ready to return, I’m starting to ask myself: “What is GDPR?” More importantly, I’m interested to know how it differs from the existing/previous data protection act and what mindset I need to adopt before returning, conscious that I may have become accustomed to the US system…

NB: Though referred to as GDPR, the UK achieves it by means of a new Data Protection Act (DPA) (2018), which was passed just two days ago. In this blog, GDPR describes the actual GDPR as well as the new DPA (2018) in order distinguish new rules with the old DPA.

What is GDPR?

GDPR is modernizes data protection laws to account for developments in the collection and use of personal data by government and businesses. It expands consumer rights whilst also increasing the obligations on those that hold personal data and penalties for non-compliance. For example, the new law is clearer in articulating the requirement for organizations to gain consent for holding your personal data and hence the barrage of emails.

How much does it really differ from the previous Data Protection Act?

Thankfully, the Information Commissioner’s Office (ICO) states that most businesses, if already in compliance of the old law, will have few changes to make to ensure compliance with the new Act.

The definitions of personal data are the same as previous regulations: anything that may allow an individual to be identified (directly or indirectly)… There is also a special category called sensitive personal data which indicates an individual’s political and religious beliefs, sexual preferences and even racial background and gender.

The rules on holding and processing personal data mostly remain unchanged in that there must be a legitimate reason for information to be collected and maintained (consent is but one of these bases for collect – thus lack of consent does not prevent an organization holding or collecting your personal information). These are mostly the same as those for the DPA but GDPR introduces stricter accountability and transparency requirements as well as requiring public bodies to consider a new “public task”. From my research of the topic, the various bases allow the army to hold and process personal data for most tasks, including obvious HR data for employment and pay/tax purposes as well as your unit asking for and holding things such as personal contact details and your car insurance information:

Some of the bigger changes include increased accountability/governance requirements including the drafting of “data protection policies” and “data protection impact assessments”. Organizations are also now specifically required to report breaches to the ICO and affected individuals within 72 hours (rather than be swept under the carpet in fear of the reputational damage). The information owner/consumer also now has better rights including free access to any information held on them and the relatively new concept of the “right to be forgotten” – Individuals have the power to compel organizations to delete their personal data when it is no longer relevant for the reason it was obtained, or if consent is withdrawn.

The new fines are also large. Small offences can have penalties of up to 10m Euros or 2% of an organization’s turnover; larger offences can have fines of double this (20m euros or 4% of turnover). This is a significant increase compared to the current 500k GBP max allowed by the DPA – this explains the apparent panic amongst business and the desire to demonstrate compliance by getting you to re-consent to them holding your data.

What does this mean for us as engineers and also officers in the army?

Under DPA and now GDPR, the army is required to document why information is held, what is to be stored, for how long and with descriptions of the level of security put in place to protect it. GDPR also now requires a Data Protection Officer (DPO) be employed to supervise this work, monitor compliance, and act as a point of contact for employees etc… I can imagine this being performed at a service level so I predict GDPR will change little from a regimental perspective. However, this assumes the regiment is in compliance with DPA to begin with!

The main issue with GDPR from the perspective of military officers is that the increased requirement for accountability and the larger fines make it even more important that use of personal data is properly recorded including holding registers of who has access to personal data and the various locations/files where it’s stored. This may sound simple but closer reflection indicates office failings can be rife. For example, contact lists, nominal rolls of personnel attending certain exercises or use of spreadsheets for managing employees all involve use of personal information (names and contact or employment details such as rank or regimental number); each record or working document should be registered but my experiences suggest this is rarely done to the level required by DPA, and now GDPR… The effect of GDPR on regimental life might be greater than it otherwise should be.

Construction sites too must also consider the rules of data protection. Sign in sheets for attendance at inductions, tool box talks, and even time-sheets all contain personal information and thus fall under data protection requirements. Though I have experience of this, my gut tells me that construction sites likely perform similarly to the army (good corporate attention to DPA but less so at lower levels or for certain areas).

GDPR is therefore just as important for construction and military organizations as it is for big tech firms. As already described above, specific consent is not necessarily required for this information to be stored if there are legal or contractual requirements for holding the information (eg Health and Safety Rules for inductions being attended etc… or contractual needs to monitor working hours). This means that GDPR won’t result in construction companies being required to include ‘opt in’ boxes for these sheets etc… However, the implications of GDPR in how the organization governs the process, maintains and secures the records, and complies with requests to share information on what data it holds on individuals is potentially big so shouldn’t be ignored.

Do I need to be concerned coming back from the US and entering a whole new world of data protection?

Thankfully, no. The USA is not too dissimilar to the UK in terms of data protection and privacy rules, though there are obvious differences, particularly in terms of terminology. The legal responsibility to safeguard personally identifiable information (PII) stems from the Privacy Act of 1974. PII is similar to the UK and EU terminology for personal information except it only includes information that allows direct identification; PII doesn’t include items like transactions histories, likes and hobbies which might allow identification when combined together i.e GDPR is broader than American data protection.

Because of a more pervasive private healthcare industry, the US also places greater emphasis on personal health information (PHI) which is regulated under additional legislation – however, PHI is beyond the scope of this post and our interest as engineers.

The US data protection rights provided under their 1974 Privacy Act are relatively strong in preventing disclosure without the consent of the information owner except under certain exemptions such as ‘routine use’ (the reason for the data’s collection and storage) and legal requirements etc that pretty much mirror those covered by DPA and now GDPR.

In terms of penalties, those failing to comply are subject to criminal and civil penalties (unliquidated damages plus reasonable attorney fees, criminal records and fine of up to 5,000 dollars). The US fine appears paltry compared to those of both DPA and GDPR and suggest reasons why companies in the USA may be more lax about breaches. Thankfully, release of PHI is more severe, with individual fines of up to $250k and ten years in prison for disclosing health information for commercial gain.

My personal experience and recent research suggests the greatest difference is that US companies tend to treat data protection as a legal issue related to the civil damages rather than the moral responsibility to protect an individual’s privacy. Because of this, I’m confident the transition back to the UK and the new GDPR will be relatively easy and simple.

However, one can’t be complacent. If anything, GDPR reminds us that it’s important to keep data protection in mind when establishing any new site/project. It relates perfectly to our project management training and the need to establish good governance and documentation procedures from the very beginning. It is, in the end, a moral and legal obligation that we protect the privacy of those we work with/for.

Saving “Piles” of cash

While not something I am directly involved with on my site, I came across this method being used in the dressing of pile cages in a bid to save both money and time further down the line and thought it was worthy of a quick post.

The works here on the North Portal includes the construction of a “waterproof box” inside which the two Tunnel Boring Machines (TBMs) will be built and launched, followed by further construction to complete the portal structure to its final glory as depicted in Fig 1.

Fig 1. Artist Impression of the North Portal

In broad outline we are installing a Continuous Flight Auger (CFA)/bored secant pile horseshoe and then excavating to ~20m before pouring a base-slab to key in with the pile wall to provide that box which will hopefully keep the water out. (The open end of the horse shoe is to be closed off by means of a grout curtain, or using cutter soil mixing (CSM))

In order to facilitate that connection between base slab and wall, deal with uplift and ensure a waterproof structure, couplers are being installed in the secant pile cages to allow the tie in of rebar once we get to depth, see Fig 2.

Fig 2. Pile wall/base slab tie in (Auggy, age 5)

The 40mm bar and coupler can be seen below as well as the setting within the reinforcement cages;

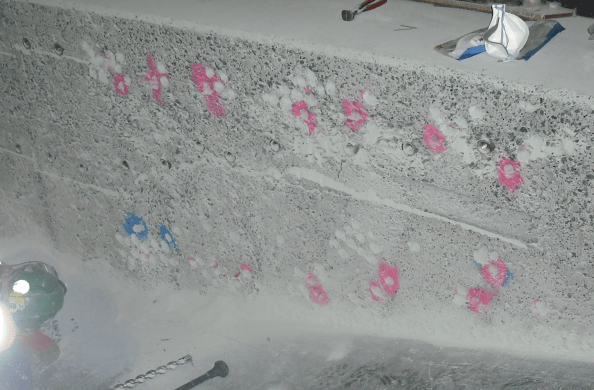

This might be how the cage is traditionally dressed before being set in the pile. The fun then begins once the excavation has reached depth and the couplers need to be located prior to establishing the base slab. Reminiscent of a game of pin the tail on the donkey, locating the couplers can be quite tricky, see Fig 5, and the hydro-demolition technique used quite expensive.

Fig 5. Find the Coupler

In order to avoid this the piling team have decided to used polystyrene and plywood to block out the area of the pile around the coupler. Adding a little bit of extra faff to the dressing of the cages will hopefully pay dividends when we get to depth in the excavation.

Fig. 6 Dressed cage

I will let you know how it goes. Hopefully interesting and maybe useful for some, though I’m sure it is not the first time it has been done.

* On a side note the piles going in at the headwall of the portal are using Glass Reinforced Plastic (GRP) instead of steel reinforcement. This is to avoid unnecessary wear on the TBM cutting heads before they even start! (I hadn’t heard of that being done before)

Grouting a tree

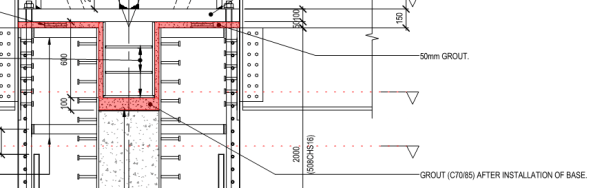

This load-bearing architectural feature called a tree column is causing some problems.

Grout will be poured into the void shown in red after the base has been installed. The designer/ Mace/ architect combo are worried that there will be voids in the grout.

Suggestions so far have been:

a) To measure the volume of grout poured in.

b) A mock-up has bee created to test construction and finish. They are proposing to cut this in section to check the grout.

The client weren’t satisfied with Option a and option b is ok but doesn’t check the actual tree columns.

My idea is to do option A and then use electrical imaging on both the mock-up and final tree-columns. Is this feasible, can electrical imaging be used for this type of thing? or are there other alternatives?

Flows and Loads

E&M’s will remember the tricky task on our first project of trying to guess the population for a deployment before being able to even think of starting our Water and Wastewater calculations. Gatwick currently has me looking over two sets of educated guesswork on a similar but altogether different issue. How do you estimate the population of a corridor?

How to meet nICE people abroad

Engagement with Institutions when Seconded Overseas

One of the attributes considered by all institutions during Professional Review is a candidate’s level of commitment to their respective institution. UK based students are able to show their commitment through their attendance at institution events and engagement with wider institution activities. Though all the institutions have an overseas presence, the footprint of their overseas members and events is often vast and spread across entire continents. This hampers the ability of overseas students to effectively connect with their institutions and limits their exposure to valuable personal and professional development opportunities.

This blog post will explore how to successfully engage with your institutions when deployed overseas and the developmental opportunities I have found during my short tenure in the USA.

Recommendations

For the benefit of all, current and future overseas students are advised to note the following recommendations:

- Contact your institution’s international representative.

- Blog about your own experience.

Additionally, the Professional Engineering Wing is invited to note the following recommendations:

- A centralised list of international institution contacts should be established and disseminated to future overseas students.

- The Chief Instructor should meet with Dr. Peter Goodwin during his next visit to the US and potentially discuss the opportunity of PET students working closely with UMCES beforehand.

First Contact

I initially reached out to the ICE delegate for the USA to try and identify what ICE activities and events are run in the US. Whilst I received some useful information he was unable to provide me with anything of substance. Success came when I reached out to Deborah Oyelaja, ICE’s International Administrator. Deborah maintains a database with the location and contact details of all ICE members located overseas. Using her database she was able to pass my details onto all the ICE members on her books living in the vicinity of Baltimore. The vast majority of the ICE members she contacted on my behalf reached out to me and I have received invites to attend a wide variety of CPD activities across the North Atlantic Coast.

The ICE only has a formal presence in New York. Their planned events and activities can be found on their webpage – www.iceusa.org. The president of the ICE NYC society has invited me to attend their events, which occur quarterly. Outside of NYC, a number of ICE members have volunteered to host myself during a visit to their in-country facilities. They have also been kind enough to extend this invitation to the other PET Students, Cs and E&Ms, who are also located in the States.

CPD Opportunities

Between NYC Society and the ICE members that have reached out to me, I have been invited to the following activities:

4 May 18 Visit Horn Point Laboratory, UMCES

5 May 18 IMET Open House

18 May 18 Lunch with US DoT representative.

21-22 May 18 Transport Research Board, Washington DC.

TBC Jun 18 ICE NYC Debate

Whilst not all of these activities may be as fruitful as others, making contact with professional engineers and world-leading academics will always be a worthwhile activity.

Horn Point Laboratory Visit – 4 May 18

Dr. Peter Goodwin is a Chartered Civil Engineer and world-renowned expert in ecohydrology. Currently the President of UMCES he is a key influencer in Maryland and was very eager for the other PET students and I, to visit Horn Point Laboratory. On 4 May 18, the other 3 PET students in-country and I took him up on the offer to visit one of UMCES’s facilities.

One of the responsibilities of USACE is the maintenance of waterways for shipping operations. For USACE Baltimore District this includes dredging to keep the waterways open, underwater construction of reefs and channels as well as the responsibility for the water quality of the Chesapeake Bay. UMCES are a key partner in this element of USACE’s mission and are consulted on the sustainability of dredging bay and the maintenance of the quality of the water.

Horn Point Laboratory is an oyster hatchery. Oysters are key to maintaining the water quality of the bay through denitrification. Each adult oyster can purify 115l of water per day. Though the visit was largely focussed on how the laboratory operates the wider discussion into the environmental aspects of sustainability and the underwater civil engineering challenges of building and maintaining oyster beds were exceptionally beneficial.

Figure 1 – Heated Beds used to simulate spring and speed up the reproductive cycle of the Oysters.

Whilst the interest for a Civil Engineer was limited, the Electrical and Mechanical works were extensive and cutting edge. Furthermore, the control system utilised to heat, feed and replace the water for the oysters was exceptionally intricate.

Dr. Goodwin and the other academics I met at the facility are exceptionally eager to host future visits and have extended their visits to UMCES remaining facilities. From a ‘C’ perspective I feel the most valuable area to look further into would be the natural flood prevention measures which UMCES take the lead on. For ‘E&Ms’, there is a huge scope of opportunities – UMCES are constantly investing in optimised their electrical and mechanical works, with most of their optimisation ideas coming directly from postgraduate Thesis work.

Figure 2 – Group Photo with Dr. Goodwin overlooking the Chesapeake Bay.

Dr. Goodwin has also invited me to attend some upcoming conferences with him over the summer in New Orleans and Panama – though I suspect I may have to pay for my flights to go this far afield for CPD. He also is very eager to establish a permanent relationship between UMCES and PEW, one of which I feel would be of great benefit.

Summary

Though Horn Point Laboratory didn’t prove to be the opportunity I had hoped from a purist Civil Engineering point of view, it was still an exceptionally valuable visit. From a Chartered Professional Review perspective, I have shown my willingness to engage with the ICE and gained some valuable sustainability and environmental knowledge that I would not have otherwise acquired.

I feel the opportunity for PEW students to work closely with UMCES is an excellent one, particularly for E&Ms. Not only might it yield an excellent opportunity to produce an engaging TMR or Thesis but it also ties into the wider defence engagement mission which is a component for ensuring this valuable attachment to USACE is maintained.

Useful Contacts

The ICE’s International Administrator contacted all the ICE members listed as being located in North Eastern USA and made my initial introduction to them all. I wholeheartedly advise all ICE members seconded abroad to contact Deborah.

Deborah Oyelaja

ICE International Administrator

Email: deborah.oyelaja@ice.org.uk

Tel: +44 (0) 20 7665 2130

Dr. Peter Goodwin is the president of UMCES, his Biography is located here and more information on UMCES can be found on their website – www.umces.edu. I feel Dr. Goodwin is a valuable contact and recommend trying to establish a permanent relationship with his organisation.

Dr. Peter Goodwin CEng

President of UMCES

Email: pgoodwin@umces.edu

Tel: +1-410-221-2000

Abbreviations

UMCES University of Maryland Centre of Environmental Science

IMET Institute of Marine and Environmental Technology

DoT Department of Transport

NYC New York City

USACE United States Army Corps of Engineers

Learnings on Sustainable Drainage

Introduction

My work at Baltimore District has seen me introduced to sustainable drainage practices across the whole construction lifecycle – concept and planning phases in Phase 3, construction in Phase 2, and maintenance and retrofitting (also in Phase 3)… Okay, no proper termination/deconstruction yet… so maybe not the entire lifecycle …. but you get the point.

Because of my exposure to it and it’s relative importance in gaining planning approval for a project, I thought I’d summarise some of what I’ve learnt to see if anybody else had come across it during their attachment and possibly start a conversation about any differences to UK practices/approaches. Please note that all images are most definitely NOT my own – thanks go to mostly google, and also to the US EPA!

Sustainable drainage forms part of what the US calls environmental site design – though I haven’t experienced it on attachment. In the UK such sustainable drainage practices are also accompanied with the term SuDS (Sustainable Drainage Systems), however, in the US, the philosophy, though very similar, is called LID (Low Impact Development). As a general term, however, most engineers in the US refer to drainage, flood protection etc… as SWM – pronounced ‘swim’ (Storm Water Management).

Why do we need SWM?

In a nut-shell, development tends to reduce the ability of the ground to soak up rainfall through abstraction, a term used to cover infiltration, depression storage, and transpiration etc… This results in more surface water – or run-off. This effect is best shown in a graphic such as the one below from the US Environmental Protection Agency’s technical report on the subject:

The consequences of such increases in run-off are numerous. Water quality issues include increased levels of pollutants such as nitrogen, phosphorous, and sediment reaching downstream water bodies. It can also result in changes to such a waterbody’s temperature, damaging the health of flora or fauna. In addition to the more obvious issues of flooding through increased run-off volume, water quantity changes can result in higher peak flows and subsequent erosion or scour, as well as loss of groundwater recharge, thus lowering the water table and/or reducing the base flow of local rivers and streams.

History of SWM in Maryland

SWM has undergone a significant evolution over the last 20-30 years. The more recognisable, traditional, approach to drainage used piped systems to convey untreated water quickly to a local outfall:

This practice then morphed into ‘conventional SWM’ which used large detention basins (‘dry ponds’) with a flow control device to outfall into the receiving water in a more sustainable manner. These practices mostly focused on treating quantity, though some ponds were later designed to hold a permanent pool of water. This resulted in them becoming known as ‘retention’ basins, or ‘wet-ponds’: these retention practices were able to improve water quality, in addition to quantity, as the permanent pool of water enabled settlement of suspended solids and breakdown of heavy metals prior to the water’s discharge into the receiving water. Two pictures of a detention practice are shown below:

By the early 2000’s, modern sustainable drainage was taking shape and LID was conceived as a means of delivering the benefits of conventional SWM but through de-centralised practices, close to the source of run-off. This prevents concentration of pollutants and reduces the size requirements of individual practices, making them more easil incorporated into urban designs. These ‘Best Management Practices’ (BMPs) include practices such as rain gardens/bio-retention features, submerged gravel wetlands, and green-roofs etc…. The major improvement to conventional SWM being that LID/modern SWm promotes infiltration into the ground, thus re-establishing groundwater properties and mimicking a site’s natural hydrology despite development.

Examples

The image below shows a typical LID practice beside a car park. The gutter allows water to enter a grassed area with a concrete level spreader in the mid-distance enabling a small amount of ponding prior to overflow into a heavily vegetated bio-retention area. The grate in the near-distance provides an overflow facility which is modelled simply as a weir.

But LID is not just about saving the environment. Fort Belvoir’s hospital was fitted with a stormwater harvesting system (a LID practice) that connected the roof drains and air-conditioning condensate pipes into cisterns able to hold 160 thousand gallons of water. This water is then used for landscape irrigation, saving the hospital an estimated 1.6million gallons of water per year – this represented a significant saving in the building’s running costs!

Aconex a Powerful Project Management Tool or Expensive Email and File Server?

Hello all,

For TMR 1 I am writing on the use of digital project management and communication systems as I have seen them in Multiplex compared to how a “power user” would use them compared to how I have seen/done project management and communication in the military.

To give a very quick overview if you have no idea what I’m taking about, Multiplex uses a system called Aconex which is a cloud based project management system providing a full audit trail across all project stakeholders. Once anything has been uploaded or sent it is there as a permanent record to aid in future understanding of evolution of design, contract negotiations, dispute resolutions, etc… It works fully in the cloud with only a web browser needed for access but also has powerful mobile apps which allows site based personnel to access current documents, send RFIs, log defects and respond to/create messages.

Aconex have a short sales video which describes what they do far better than I can in this very short blog, which hopefully works below.

What I don’t know is what other systems are out there and what the UK construction industry uses, so I’m asking for your help. In the comments below could I get you to let me know what systems your projects are using and give me an idea on how they are being used. Thanks all.

Once complete I will put up a summary of my TMR so you can see what my conclusion was and if there is utility for future military projects we will be involved in.

Buckingham Palace Asbestos Issues

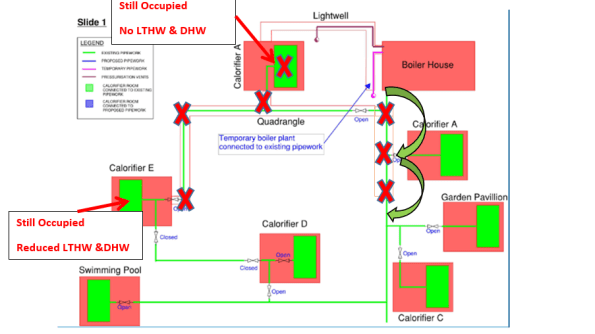

- Introduction. As this is my first blog I should give some background on my attachment. I am currently working at Buckingham Palace as part of the Reservicing Programme which aims to replace all the E&M services for the site over a 10 period. The programme is split down into 2 year projects with the first being ‘High Priority Works’ (HPW) which covers the majority of basement services, new boilers, new generators, new switchboards replacing the primary LV cables and LTHW pipes. The following projects are then 2 years per wing of the palace to replace the services from each wings plant room through to the end fixtures and fittings. We are currently constructing all the preliminary works for the programme by refurbishing office space and accommodation to use a decant space for the other wings so they can be vacated. My focus has been on the HPW and while I am doing work assisting the Design Director and Construction Director in the Programme Management Office (PMO) my golden thread through the placement is as Deputy Project Manager for HPW. In that capacity my most recent work has been reviewing and signing off the designs for HPW as part of the ongoing tender process and problem solving issues that we can see on the horizon. One such issue is the finding of asbestos in a key area.

- Asbestos Issue. As you might expect the palace is full of asbestos as it is an old building and the last major refurbishment happened throughout the 1960’s. For the most part this is well managed and the asbestos areas are clearly identified. One area that had not been counted on was the quadrangle tunnels which run inside the square in the middle on the palace and have much of the cabling and LTHW pipes.

- My role has been to lead on this issue for the PMO and investigate what options the Palace has. I am then to pull together the PMO, Royal Household Property Section (which conducts the facilities management and business a usual engineering) and the Principal Designer (WSP) to find a solution which has the least impact on the running of the palace and the project budget/timeline.

- In clearing the asbestos to allow both routine maintence and the replacement of services tunnel I have proposed two options. It can be done as pre-works before HPW in Aug-Nov 2018 approx or during HPW in Mar-May 2019 approx. Both solutions are technically possible. Of note the asbestos specialist has identified that to strip the lagging of the pipes they must be cold due to the requirements of the HSE. By clearing earlier there will be a significant reduction in heating and hot water to the East Wing over this time period which must be mitigated as the Palace will accept no disruption to normal business.

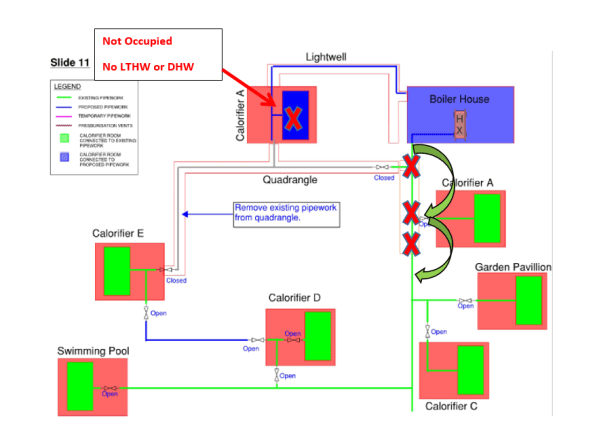

- Option A – Clear ASAP. In this option the East Wing’s centrally supplied heating and DHW will be stopped for a period likely to be 2-3 months. The feed to Calorifers A, C and D will be via a temporary pipe. This temporary pipe could feed through the quadrangle at surface level or external to the building to the South. The effects of stopping LTHW and DHW to the East Wing can be mitigated by the following methods.

- Using immersion heaters.

- Installing point of use hot water heaters for taps, showers.

- Using plug in temporary heaters.

Figure 1. Showing Option A

- Option B – Clear on HPW. In this option HPW will continue as planned with no access allowed into the quadrangle tunnel. The first time HPW will need to access the tunnel is likely to be in early 2019. The same work as Option A will be required to bypass the South Quadrangle tunnel with temporary pipework. By this point the following will have already occurred.

- The boilers will have been fully replaced.

- The connection pipe between Calorifiers D and E will have been replaced with a larger pipe.

- A lightwell connection from the boilers to Calorifier A will have been made to bypass the LTHW primary ring.

Figure 2. Showing Option B

- Areas for investigation. I’ll let you all know how I get on. For the moment my areas for further investigation are as follows.

- How can Option A’s effects be mitigated on the East and North Wing through immersion heaters and point of use heaters?

- What is the best route for South Wing Temporary Pipework in Options A & B?

- What is the best type of temporary pipework (I’m looking at Victaulic Joints)?

- Investigate a variation to both options to use a temporary boiler in the garden.

- What heating and DHW can be currently transmitted to the North Wing via the link and is this enough for a Summer/Autumn Load?

I THINK THIS WALL MIGHT FALL OVER

Introduction

I’m currently on Phase 2 of the course in Sunny Australia. Hi.

I am working on ‘the Wynyard Project’ which involves building a new 32 floor tower over an underground rail station whilst renovating two neighbouring, heritage buildings.

Figure 1 – Wynyard Project architectural render

This wonderful story is about a risk I encountered when looking at demolition plans for 285 George St building (one of the two heritage renovations).

285 George St (figure 2) is a building originally constructed for use by Peapes Tailors but was then altered in the 70s as it was converted into offices. Substantial renovation is required to turn the building into modern office and retail space. Additionally, the building does not currently meet seismic codes or fire regs therefore vast structural alterations are required.

Figure 2 – 285 George St heritage building

The Plan

Demolition and structural investigations are happening concurrently and therefore it is important to identify risk and alter the demolition plans as we go.

In essence, the current demolition plan is to remove some roof structures, create penetrations through the building (for new fire stair, risers etc), demolish all internal fit-out, amend floor structures, and amend openings.

The Risk

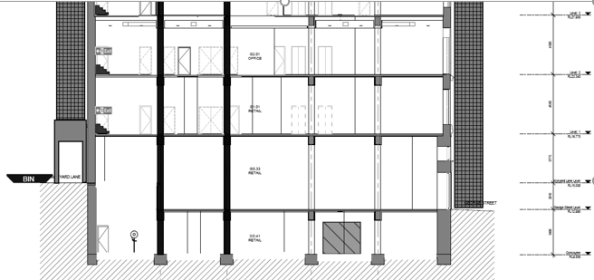

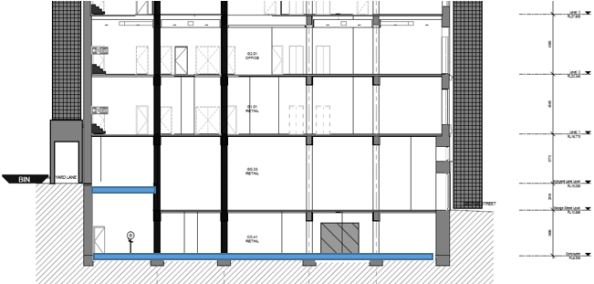

I was asked to look at the material load-out for the staging of the planned demolition and as doing so, many risks popped up. In particular, I was concerned with the removal of Slab on Ground, George St level Slab and Wynyard Lane Level Slab (see figure 3, 4 & 5 (bottom left area of each)).

Figure 3 – Section prior to demolition

Figure 4 – Section post demolition

Figure 4 – Section post demolition

Figure 5 – Section post demolition with new slabs constructed

Figure 5 – Section post demolition with new slabs constructed

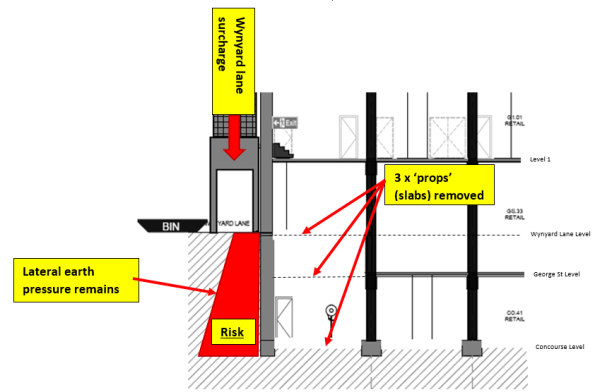

I believe the removal of the slabs causes several risks (the two major ones being the extended effective length of the columns and reduced number of ‘props’ for the external wall). Here I will concentrate on the risk at the Wynyard lane external wall:

Figure 6 – Risk

I think this gives me two risks within this scenario (Agree?):

- Slide at the toe once slab on ground is removed. Therefore a hinge within the wall at level 1 will also be developed.

- If the foundation holds the toe then bending and shear stresses in the span of the wall will increase when the Wynyard lane and George st level slabs are removed (same forces left to right (Ka), reduced force right to left (slab restraints) = higher bending and shear stresses in the wall)

Is it really a risk?

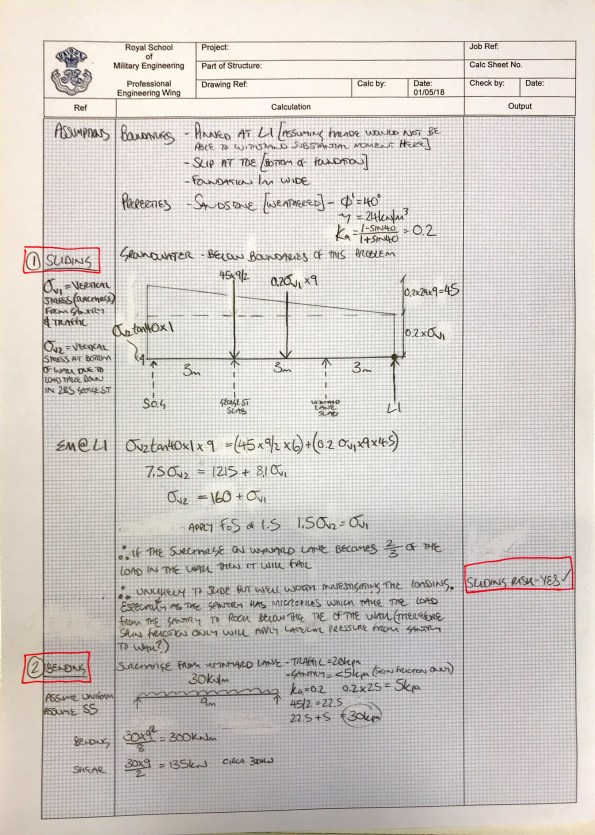

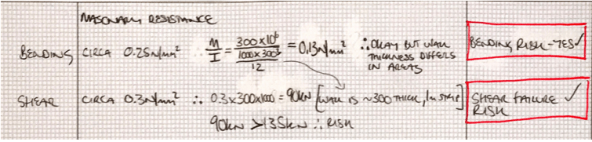

Structural investigations are underway and no results yet received therefore some large assumptions must be made at this stage (when the results are complete, a structural consultant (Robert Bird Group) will assess the issue and design any temp works required). I have attempted a very crude calculation to see whether it is a substantial risk. I have thrown in some deliberate mistakes to enhance the learning experience for us all…

Figure 7 – Crude Calcs 1

Figure 8 – Crude Calcs continued

Solutions?

Any ideas to mitigate the temporary (figure 4) and permeant (figure 5) risk?

Temp steel props during construction and permanently beef up the wall (reduces floor space/less money)?