Archive

Buckingham Palace Asbestos Issues

- Introduction. As this is my first blog I should give some background on my attachment. I am currently working at Buckingham Palace as part of the Reservicing Programme which aims to replace all the E&M services for the site over a 10 period. The programme is split down into 2 year projects with the first being ‘High Priority Works’ (HPW) which covers the majority of basement services, new boilers, new generators, new switchboards replacing the primary LV cables and LTHW pipes. The following projects are then 2 years per wing of the palace to replace the services from each wings plant room through to the end fixtures and fittings. We are currently constructing all the preliminary works for the programme by refurbishing office space and accommodation to use a decant space for the other wings so they can be vacated. My focus has been on the HPW and while I am doing work assisting the Design Director and Construction Director in the Programme Management Office (PMO) my golden thread through the placement is as Deputy Project Manager for HPW. In that capacity my most recent work has been reviewing and signing off the designs for HPW as part of the ongoing tender process and problem solving issues that we can see on the horizon. One such issue is the finding of asbestos in a key area.

- Asbestos Issue. As you might expect the palace is full of asbestos as it is an old building and the last major refurbishment happened throughout the 1960’s. For the most part this is well managed and the asbestos areas are clearly identified. One area that had not been counted on was the quadrangle tunnels which run inside the square in the middle on the palace and have much of the cabling and LTHW pipes.

- My role has been to lead on this issue for the PMO and investigate what options the Palace has. I am then to pull together the PMO, Royal Household Property Section (which conducts the facilities management and business a usual engineering) and the Principal Designer (WSP) to find a solution which has the least impact on the running of the palace and the project budget/timeline.

- In clearing the asbestos to allow both routine maintence and the replacement of services tunnel I have proposed two options. It can be done as pre-works before HPW in Aug-Nov 2018 approx or during HPW in Mar-May 2019 approx. Both solutions are technically possible. Of note the asbestos specialist has identified that to strip the lagging of the pipes they must be cold due to the requirements of the HSE. By clearing earlier there will be a significant reduction in heating and hot water to the East Wing over this time period which must be mitigated as the Palace will accept no disruption to normal business.

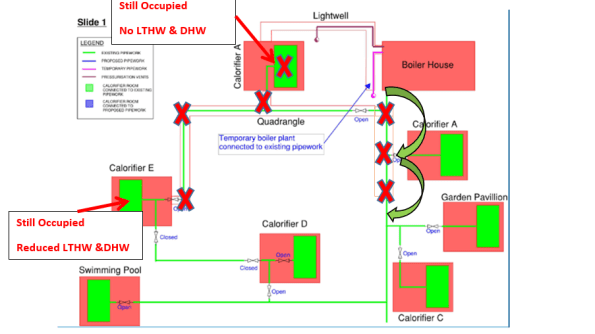

- Option A – Clear ASAP. In this option the East Wing’s centrally supplied heating and DHW will be stopped for a period likely to be 2-3 months. The feed to Calorifers A, C and D will be via a temporary pipe. This temporary pipe could feed through the quadrangle at surface level or external to the building to the South. The effects of stopping LTHW and DHW to the East Wing can be mitigated by the following methods.

- Using immersion heaters.

- Installing point of use hot water heaters for taps, showers.

- Using plug in temporary heaters.

Figure 1. Showing Option A

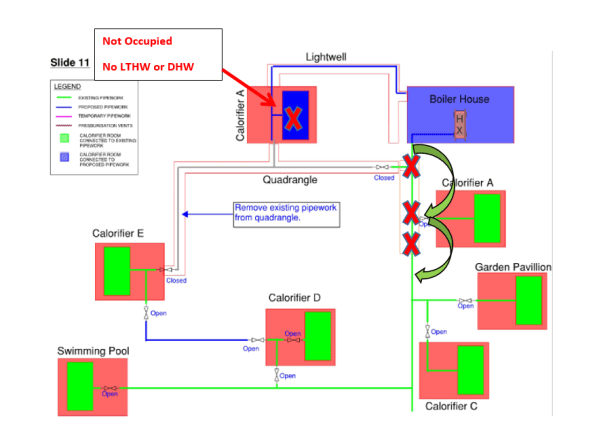

- Option B – Clear on HPW. In this option HPW will continue as planned with no access allowed into the quadrangle tunnel. The first time HPW will need to access the tunnel is likely to be in early 2019. The same work as Option A will be required to bypass the South Quadrangle tunnel with temporary pipework. By this point the following will have already occurred.

- The boilers will have been fully replaced.

- The connection pipe between Calorifiers D and E will have been replaced with a larger pipe.

- A lightwell connection from the boilers to Calorifier A will have been made to bypass the LTHW primary ring.

Figure 2. Showing Option B

- Areas for investigation. I’ll let you all know how I get on. For the moment my areas for further investigation are as follows.

- How can Option A’s effects be mitigated on the East and North Wing through immersion heaters and point of use heaters?

- What is the best route for South Wing Temporary Pipework in Options A & B?

- What is the best type of temporary pipework (I’m looking at Victaulic Joints)?

- Investigate a variation to both options to use a temporary boiler in the garden.

- What heating and DHW can be currently transmitted to the North Wing via the link and is this enough for a Summer/Autumn Load?

I THINK THIS WALL MIGHT FALL OVER

Introduction

I’m currently on Phase 2 of the course in Sunny Australia. Hi.

I am working on ‘the Wynyard Project’ which involves building a new 32 floor tower over an underground rail station whilst renovating two neighbouring, heritage buildings.

Figure 1 – Wynyard Project architectural render

This wonderful story is about a risk I encountered when looking at demolition plans for 285 George St building (one of the two heritage renovations).

285 George St (figure 2) is a building originally constructed for use by Peapes Tailors but was then altered in the 70s as it was converted into offices. Substantial renovation is required to turn the building into modern office and retail space. Additionally, the building does not currently meet seismic codes or fire regs therefore vast structural alterations are required.

Figure 2 – 285 George St heritage building

The Plan

Demolition and structural investigations are happening concurrently and therefore it is important to identify risk and alter the demolition plans as we go.

In essence, the current demolition plan is to remove some roof structures, create penetrations through the building (for new fire stair, risers etc), demolish all internal fit-out, amend floor structures, and amend openings.

The Risk

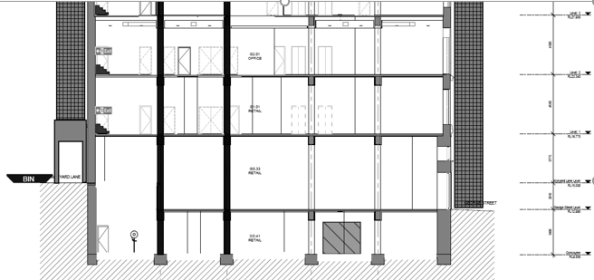

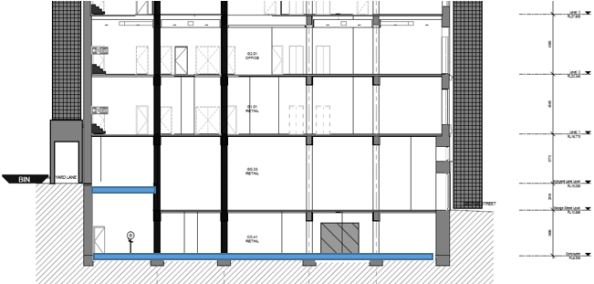

I was asked to look at the material load-out for the staging of the planned demolition and as doing so, many risks popped up. In particular, I was concerned with the removal of Slab on Ground, George St level Slab and Wynyard Lane Level Slab (see figure 3, 4 & 5 (bottom left area of each)).

Figure 3 – Section prior to demolition

Figure 4 – Section post demolition

Figure 4 – Section post demolition

Figure 5 – Section post demolition with new slabs constructed

Figure 5 – Section post demolition with new slabs constructed

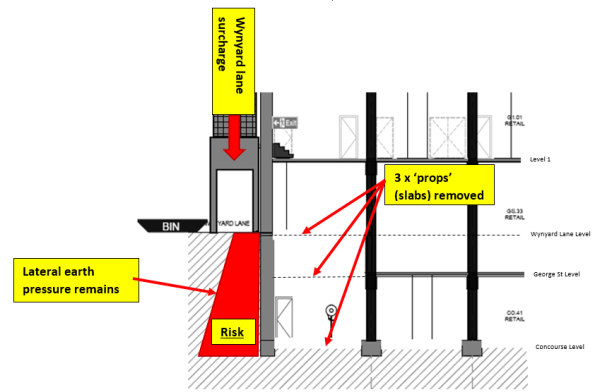

I believe the removal of the slabs causes several risks (the two major ones being the extended effective length of the columns and reduced number of ‘props’ for the external wall). Here I will concentrate on the risk at the Wynyard lane external wall:

Figure 6 – Risk

I think this gives me two risks within this scenario (Agree?):

- Slide at the toe once slab on ground is removed. Therefore a hinge within the wall at level 1 will also be developed.

- If the foundation holds the toe then bending and shear stresses in the span of the wall will increase when the Wynyard lane and George st level slabs are removed (same forces left to right (Ka), reduced force right to left (slab restraints) = higher bending and shear stresses in the wall)

Is it really a risk?

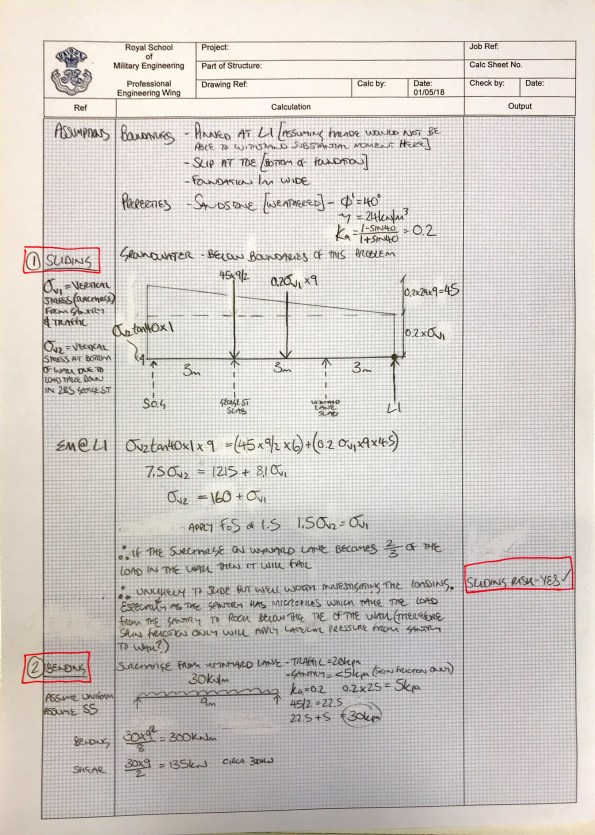

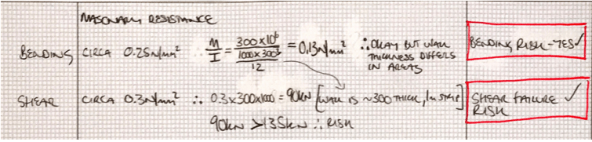

Structural investigations are underway and no results yet received therefore some large assumptions must be made at this stage (when the results are complete, a structural consultant (Robert Bird Group) will assess the issue and design any temp works required). I have attempted a very crude calculation to see whether it is a substantial risk. I have thrown in some deliberate mistakes to enhance the learning experience for us all…

Figure 7 – Crude Calcs 1

Figure 8 – Crude Calcs continued

Solutions?

Any ideas to mitigate the temporary (figure 4) and permeant (figure 5) risk?

Temp steel props during construction and permanently beef up the wall (reduces floor space/less money)?