Archive

Saving “Piles” of cash

While not something I am directly involved with on my site, I came across this method being used in the dressing of pile cages in a bid to save both money and time further down the line and thought it was worthy of a quick post.

The works here on the North Portal includes the construction of a “waterproof box” inside which the two Tunnel Boring Machines (TBMs) will be built and launched, followed by further construction to complete the portal structure to its final glory as depicted in Fig 1.

Fig 1. Artist Impression of the North Portal

In broad outline we are installing a Continuous Flight Auger (CFA)/bored secant pile horseshoe and then excavating to ~20m before pouring a base-slab to key in with the pile wall to provide that box which will hopefully keep the water out. (The open end of the horse shoe is to be closed off by means of a grout curtain, or using cutter soil mixing (CSM))

In order to facilitate that connection between base slab and wall, deal with uplift and ensure a waterproof structure, couplers are being installed in the secant pile cages to allow the tie in of rebar once we get to depth, see Fig 2.

Fig 2. Pile wall/base slab tie in (Auggy, age 5)

The 40mm bar and coupler can be seen below as well as the setting within the reinforcement cages;

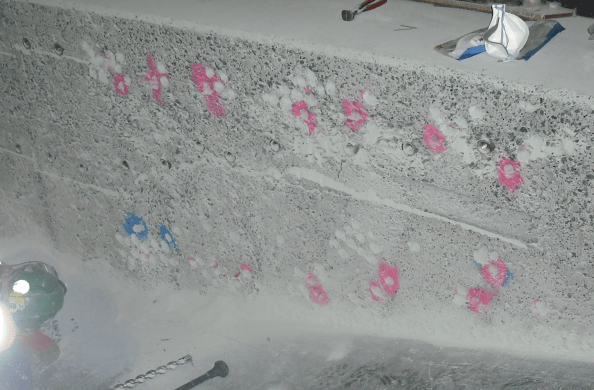

This might be how the cage is traditionally dressed before being set in the pile. The fun then begins once the excavation has reached depth and the couplers need to be located prior to establishing the base slab. Reminiscent of a game of pin the tail on the donkey, locating the couplers can be quite tricky, see Fig 5, and the hydro-demolition technique used quite expensive.

Fig 5. Find the Coupler

In order to avoid this the piling team have decided to used polystyrene and plywood to block out the area of the pile around the coupler. Adding a little bit of extra faff to the dressing of the cages will hopefully pay dividends when we get to depth in the excavation.

Fig. 6 Dressed cage

I will let you know how it goes. Hopefully interesting and maybe useful for some, though I’m sure it is not the first time it has been done.

* On a side note the piles going in at the headwall of the portal are using Glass Reinforced Plastic (GRP) instead of steel reinforcement. This is to avoid unnecessary wear on the TBM cutting heads before they even start! (I hadn’t heard of that being done before)

Grouting a tree

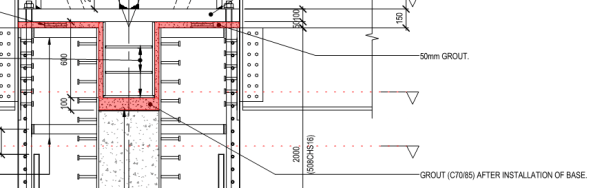

This load-bearing architectural feature called a tree column is causing some problems.

Grout will be poured into the void shown in red after the base has been installed. The designer/ Mace/ architect combo are worried that there will be voids in the grout.

Suggestions so far have been:

a) To measure the volume of grout poured in.

b) A mock-up has bee created to test construction and finish. They are proposing to cut this in section to check the grout.

The client weren’t satisfied with Option a and option b is ok but doesn’t check the actual tree columns.

My idea is to do option A and then use electrical imaging on both the mock-up and final tree-columns. Is this feasible, can electrical imaging be used for this type of thing? or are there other alternatives?