Archive

Point Cloud Survey

Just a quick one. I thought you might be interested in the point cloud surveys we have been undertaking. It has been a great resource but on this site has had significant security restrictions limiting its use to front of house areas where the public can see anyway and plant rooms to assist in services clashing avoidance. Enjoy!

Innovative Jump Form System for the Residential Tower

I have recently completed the area I was first working on and have now been assigned as the Site Engineer for vertical elements in the just started Residential Tower. From my first blog you would have seen Multiplex (MPX) fears over not winning this job and the congestion on site that would have caused. Well they needn’t have worried as they won the contract and have just started construction of the 80 story Residential Tower.

The system of jump form that has been selected is causing some excitement in the office, so I thought it was worth sharing with you here. It is apparently so innovative that most in the office have never even heard of it let alone seen it. Before we look at the new system it is worth just understanding how a traditional jump form works.

Traditional Jump Form Tower Construction

Traditional jump form systems form the core only, several levels higher that the decks. The video below shows the normal sequence for a core only jump form.

The foot print of the jump is normally only a fraction of the buildings and space is very tight at the top. Below is done pictures of the traditional jump system being used for the commercial tower on my site.

The decks are then constructed using either structural form work (i.e. bondeck which provides form work initially and then becomes part of a composite slab once the concrete has cured) or traditionally using removable form work that is supported by a lattice of props and beams. Critically this leaves the columns to be poured separately once the deck is in place. Again this is normally done using a traditional form which must be set up individually for each column adding days of delay. To get around this on the commercial tower on my site are using hollow steel sections as form work then pouring concrete into them to create a composite section. Below is some more pictures of the commercial tower this time of the the decks being constructed.

Oliver Moore (OM) Jump Form Tower Construction

This new OM jump form is radically different in that it covers the whole footprint of the building and allows the construction of all vertical elements simultaneously and at the same level i.e. the core, columns and shear walls all done at the same time and same level. When fully constructed the system also contains all structural and external façade works minimising the risk to workers and the general public. This is achieved by having a set of screens directly attached to the top of the jump which hang down 5 levels to enclose the horizontal structural works (in this case PT slabs).

From the bottom of the first screens a monorail system is connected which allows a winch system to manoeuvre around the whole of the building for façade install. This eliminates the risky use of mini crawler cranes that have to dangle massive glass panels over the buildings edge to get them installed. These works are similarly enclosed by a second screen system cantilevered from the first hanging down 2 levels. The connection to the primary jump system means both screens and monorail will move as the system does. When this happens an externally complete building will emerge from out of the bottom of the jump.

Multiplex have set an ambitious completion program that has been written into the contract. Once fully launched the jump has been set a 5 day cycle which means all steel work will have to be completed in 8 hours and post tensioning work completed in 4. I have yet to dig in to the program so don’t ask too many questions on this just yet.

The new jump system is also getting an extensive vertical transport system to support the cycle time. The movement of men and materials will be supported through a number of systems, three high-speed site hoists will be installed along with two tower cranes and an integral cantilevered jump lift. A single car site hoist will move through penetrations left open in the podium slabs before climbing the exterior while a double car site lift on the other side of the building will climb up the exterior of the tower from ground level. These hoists will be extended in line with the jumps to ensure quick access is always maintained to the top of the jump form. There is also a cantilevered integral materials lift that is connected to the jump system moving as it does, the lift will be used for the movement of materials up to 5 levels down from the top deck. This is needed as normally the cranes would land materials directly on the decks but with the jump system covering the decks materials must be landed on the decks and subsequently transported down.

This is all shown diagrammatically in the images below however I suspect they won’t come up large enough to see the detail, so please click here to access the source documents.

Hopefully that has been interesting and provided a snap shot of what I am up to. Please feel free to fire any questions you have at me and I’ll do my best to answer them. The jump isn’t on site yet so I’ll probably follow this post up in a few months once it’s running to give you some real pictures and let you know how it works in reality.

Seismic Assessment of a Structure – Fundamentals (Direct Displacement Based Design)

Introduction:

- I’m trying to get my head around some seismic design for the building I’m working on. I’ve done a bit of reading – here is a quick description of my understanding so far, anybody else done any seismic and can collaborate? Any thoughts or corrections?

Assumption:

- EQUAL DISPLACEMENT RULE. (total displacement of an element is roughly the same whether you treat it as fully elastic or non-linear) – proven empirically but the theory is that energy is dissipated when a material yields and therefore the demand on the element is reduced.

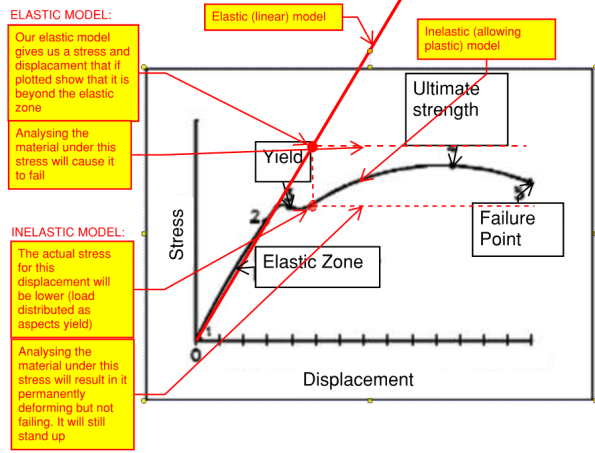

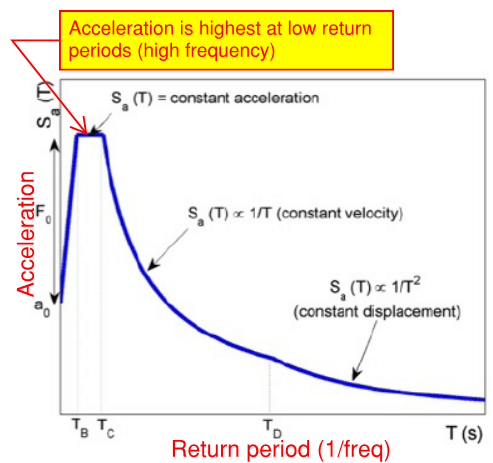

Graph:

Process:

Process:

Elastic Model (or elastic calcs) – FORCE BASED DESIGN (what we are used to):

- Input: Apply seismic loading

- Output: Displacements and stresses

- Compare displacements to SLS criteria (eg inter storey drift max = 0.015 x storey height)

- Check materials can withstand the stresses (in the example in the graph, it will fail)

- However the results may not be truthful to how the material/structure will actually behave – you may be in the plastic zone and as a result, overestimating the stress in the material. There are factors you can apply to bring the stress down but a more accurate approach is to use DIRECT DISPLACEMENT BASED DESIGN

Inelastic model (or non-linear calc iterations) – DISPLACEMENT BASED DESIGN:

- Input: Displacement – input the displacement our elastic model gave us (equal displacement rule). (if you are designing a new build then set your target displacement and start here). The target displacement is then sub divided to create start and end points for each stage of analysis.

- Iterations must be conducted in order to find the critical mode of deformation.

- Output: Stresses

- Check materials can withstand the stresses (in the example above, it will now pass (permanent damage but no collapse))

Other:

- When setting up the model, applying high levels of fixity at connections is conservative (the opposite to what I think is intuitive) because:

Summary:

- Force based design does not allow an accurate estimation of stresses within a structure for material that is beyond yield. Direct displacement based design allows for a more accurate estimate because displacements are more proportional to non-linear behaviour/energy dissipation?

Lighting System Replacement

I am managing a project to replace the lighting system in a British Airways Container Handling Store at Heathrow Airport. The store is a 75m x 50m portal frame warehouse, fitted with 20 lanes of industrial conveyor belts. The facility is used to temporarily store aluminium air-freight containers between connecting flights. As you might imagine, it is a hive of activity with a continuous flow of electric tugs towing long trains of baggage trailers.

The existing system consists of 192 x Thorn Titus 3x 49W T5 fluorescent lights (incl. 54x self-contained emergency variants) and 13 x 400W external halogen floodlights, which are all connected to a central Digital Addressable Lighting Interface (DALI) control system. The installation has now reached the end of its life. Several luminaires have failed in addition to three of the six DALI gateways which means the lighting in certain sections of the building cannot be controlled. A recent test of the emergency lights also revealed that the batteries were only lasting for 25 minutes – well below the required 3-hours.

Another driver for this project is energy efficiency. Since most of the lights are used on a 24hr basis, there are savings to be made by replacing the fluorescent and halogen lights with LED equivalents. Photos of the existing installation are shown below.

Luminaire Selection

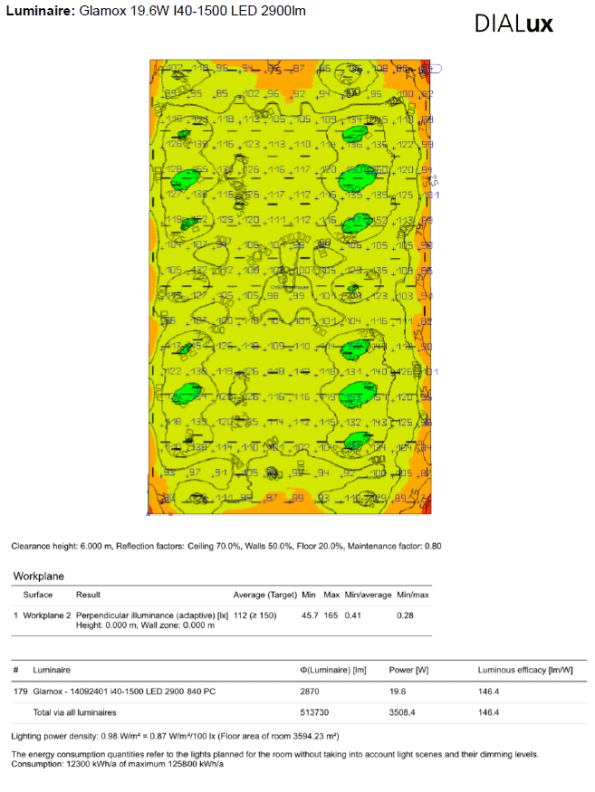

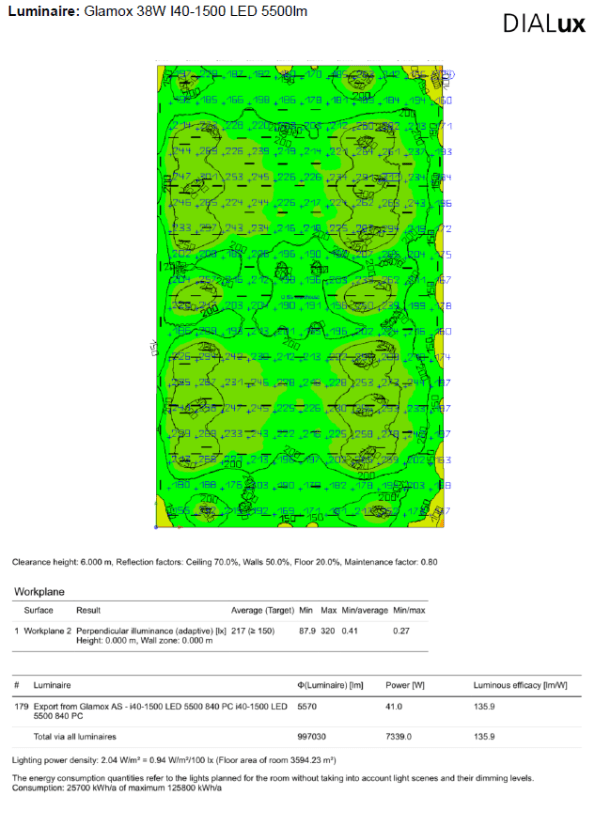

I was initially advised to install Glamox 19.6W I40-1500 LED 2900lm luminaries in the warehouse, as there was surplus residual stock of these units. However, I was concerned that these luminaires would not provide sufficient output so I obtained the necessary Eulum data files from the manufacturer and undertook a more thorough analysis using DIALux.

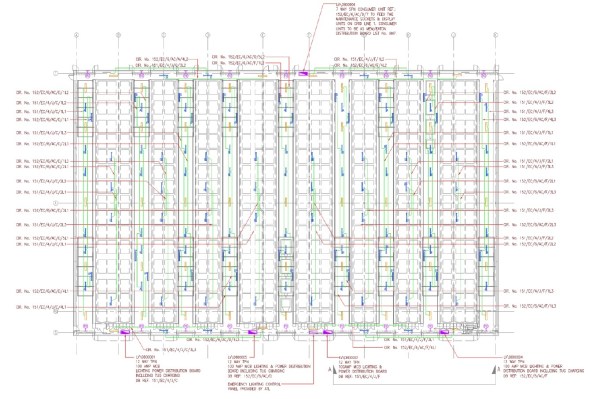

Heathrow Airport Limited (HAL) Lighting Standards stipulate a the lighting requirement in all areas of the airport. Cargo handling facilities must be lit to 150 lux at floor level with a limiting glare index of 25 and max power density of 2 W/m2/100 lux. I imported the AutoCad schematic (shown below) of the facility into the DIALux and used this as a template to position the luminaires.

Container Handling Store AutoCad Schematic

I simulated the luminance produced by the 2900lm units based on a maintenance factor of 0.8. The results of this analysis confirmed that these luminaires were not suitable. I experimented with various different options which enabled me to confirm that the Glamox 38W I40-1500 LED 5500lm would provide sufficient lighting. The results of this analysis are shown below.

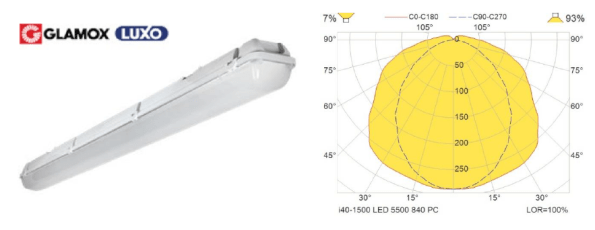

I decided to use Glamox 38W I40-1500 LED 5500lm luminaires, which are slightly brighter than required. However, the power output can be reduced to the required level using the DALI controls., which will also reduce the energy consumption. The power output may need to be increased in the future to compensate for performance degradation. I also selected Thorn 205W 96L70-740 LED 24394lm floodlights for the external areas of the warehouse. Images of these luminaires are included below.

Glamox I40-1500 38W 5500lm LED DALI PC

Thorn 205W AFP 96L70-740 W LED Floodlight

Lighting Controls

Having not had any experience with DALI lighting controls I undertook further research and consulted with engineers from Schneider Electric to gain a better understanding of how these systems work. This research enable me to produce a detailed scope of works and proposed installation methodology to maximise efficiency and minimise the impact on operations. A picture of the DALI gateway is included below.

DALI / KNX Gateway N141/02

Each gateway can interface with up to 64 luminaries, providing control and fault diagnostic capability. They also provide an interface with the KNX system, which is standardised OSI-based communications protocol, which allows the lights to be monitored by the Building Management System (BMS). I have advised the principal contractor (Dyer & Butler) to employ Schneider Electric as a subcontractor to commission the new DALI system due to their specialist expertise in this area.

Constraints

Operations. The CHSS facility is operational during working hours, therefore all works must be undertaken at night between 1130-0430 hrs. This leaves a very short window of opportunity after allowing for set-up and clear-up time. I am therefore working closely with the contractor to maximise efficiency by planning how the work will be sequenced and the methods that will be used.

Access. I have confirmed that a scissor lift can be used to access the lights above the walkways. However, some lights are fitted above the automatic, multi-directional conveyor. This system will need to be isolated to ensure that it will not operate while the work is being done. I considered the possibility of laying plywood panels over the conveyors to provide a stable surface for a scaffold access platform. However, this would necessitate the removal of the guardrails which would have been time consuming and further reduce the working window. After considering the size of the manoeuvring space available and the height of the guard around the conveyor, I identified a suitable MEWP for this application. A video of the Nifty Heightrider 12 is included below together with its capabilities. I advised the contractor to hire this equipment to test its suitability during the pre-works survey.

Stakeholder Engagement

There are various stakeholders involved in this project as show below:

- Contractors. I have established a good relationship with the contractors (Dyer & Butler Electrical and Schneider Electric) to refine the methodology and confirm the alterations that will be required to the wiring system.

- Suppliers. The lighting suppliers have assisted with the process of selecting the appropriate luminaires to ensure compatibility and provided the data to enable me to undertake a lux assessment.

- Assurance. Prior to commencing works, I must gain approval from the Chief Electrical Engineer who provides technical assurance of new installations / modifications to the electrical systems.

- Safety. All works at Heathrow require a necessary work permits and authorisation to proceed, which can involve a protracted process – but this is essential to de-conflict works with other projects. In addition, this work will require electrical switchboards to be isolated which must be performed by a nominated Authorised Persons via the Airport Operations Centre in accordance with the HAL Electrical Safety Rules.

- Customer. It will also be essential to maintain a continuous dialogue with BA to ensure this work does not affect operations. I will also need to coordinate with them to ensure the baggage lanes are clear each evening, to facilitate access to the lights and avoid the potential for delays and compensation events.

Financial Appraisal

Based on my analysis of the power and operating times of the existing lights, the current system consumes a total of 212,000 kWh per year. Heathrow Airport currently pays a special rate of 9.47 pence per kWh. Therefore, the existing system costs just over £20k per year to run.

By replacing the existing lights with LED equivalents and optimising the control system with PIR sensors and upgraded DALI gateways, the power consumption of the new system is expected to be reduced to 60,000 kWh. The cost to light the facility will therefore reduce to £5.7k per year, which will deliver annual savings of £14.3k.

Taking account of the costs for new luminaires, DALI gateways and installation fees, the final budget for this project has been estimated at just under £50k. Therefore, based on energy savings alone this project is expected to deliver a payback period of 3.5 years.