Lighting System Replacement

I am managing a project to replace the lighting system in a British Airways Container Handling Store at Heathrow Airport. The store is a 75m x 50m portal frame warehouse, fitted with 20 lanes of industrial conveyor belts. The facility is used to temporarily store aluminium air-freight containers between connecting flights. As you might imagine, it is a hive of activity with a continuous flow of electric tugs towing long trains of baggage trailers.

The existing system consists of 192 x Thorn Titus 3x 49W T5 fluorescent lights (incl. 54x self-contained emergency variants) and 13 x 400W external halogen floodlights, which are all connected to a central Digital Addressable Lighting Interface (DALI) control system. The installation has now reached the end of its life. Several luminaires have failed in addition to three of the six DALI gateways which means the lighting in certain sections of the building cannot be controlled. A recent test of the emergency lights also revealed that the batteries were only lasting for 25 minutes – well below the required 3-hours.

Another driver for this project is energy efficiency. Since most of the lights are used on a 24hr basis, there are savings to be made by replacing the fluorescent and halogen lights with LED equivalents. Photos of the existing installation are shown below.

Luminaire Selection

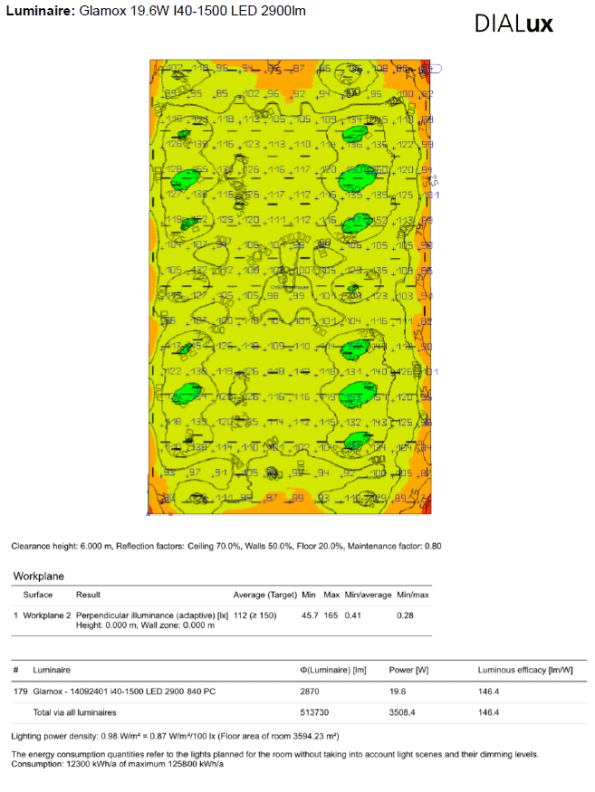

I was initially advised to install Glamox 19.6W I40-1500 LED 2900lm luminaries in the warehouse, as there was surplus residual stock of these units. However, I was concerned that these luminaires would not provide sufficient output so I obtained the necessary Eulum data files from the manufacturer and undertook a more thorough analysis using DIALux.

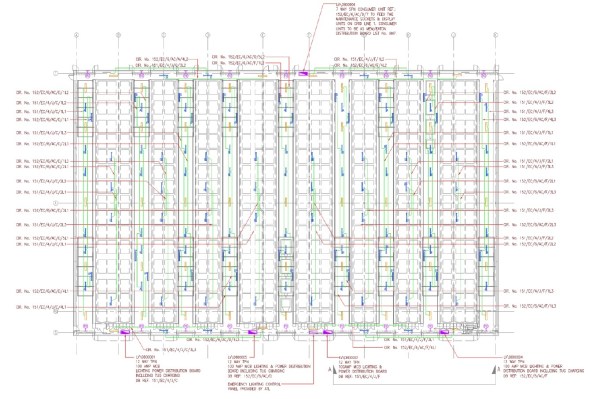

Heathrow Airport Limited (HAL) Lighting Standards stipulate a the lighting requirement in all areas of the airport. Cargo handling facilities must be lit to 150 lux at floor level with a limiting glare index of 25 and max power density of 2 W/m2/100 lux. I imported the AutoCad schematic (shown below) of the facility into the DIALux and used this as a template to position the luminaires.

Container Handling Store AutoCad Schematic

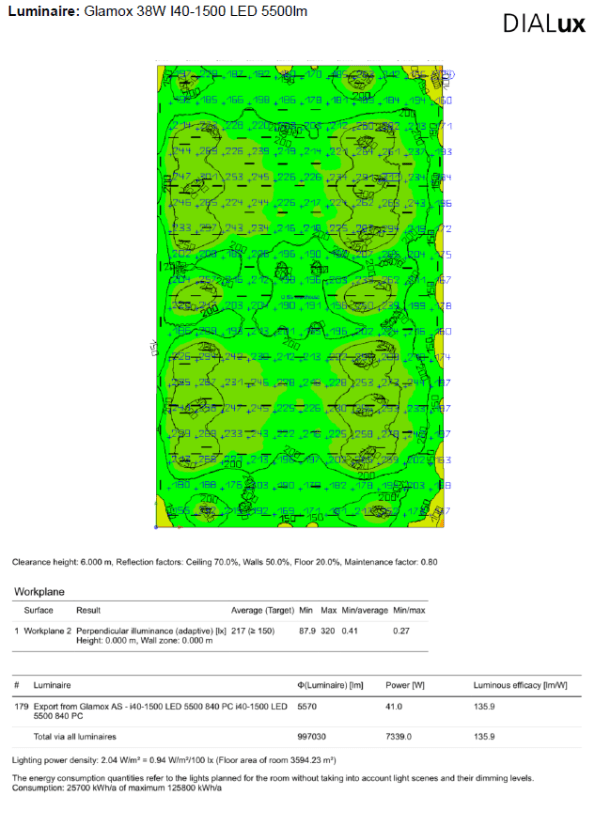

I simulated the luminance produced by the 2900lm units based on a maintenance factor of 0.8. The results of this analysis confirmed that these luminaires were not suitable. I experimented with various different options which enabled me to confirm that the Glamox 38W I40-1500 LED 5500lm would provide sufficient lighting. The results of this analysis are shown below.

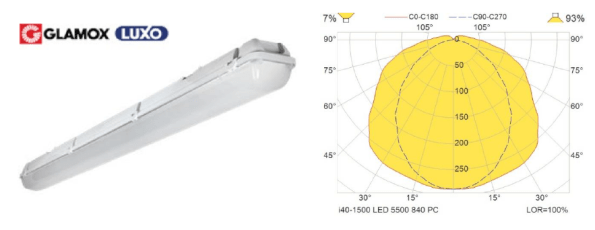

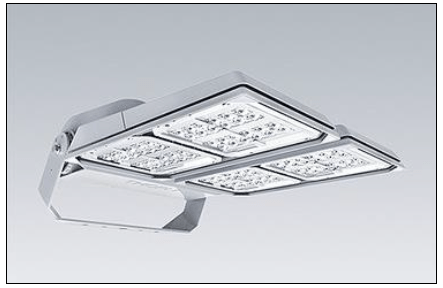

I decided to use Glamox 38W I40-1500 LED 5500lm luminaires, which are slightly brighter than required. However, the power output can be reduced to the required level using the DALI controls., which will also reduce the energy consumption. The power output may need to be increased in the future to compensate for performance degradation. I also selected Thorn 205W 96L70-740 LED 24394lm floodlights for the external areas of the warehouse. Images of these luminaires are included below.

Glamox I40-1500 38W 5500lm LED DALI PC

Thorn 205W AFP 96L70-740 W LED Floodlight

Lighting Controls

Having not had any experience with DALI lighting controls I undertook further research and consulted with engineers from Schneider Electric to gain a better understanding of how these systems work. This research enable me to produce a detailed scope of works and proposed installation methodology to maximise efficiency and minimise the impact on operations. A picture of the DALI gateway is included below.

DALI / KNX Gateway N141/02

Each gateway can interface with up to 64 luminaries, providing control and fault diagnostic capability. They also provide an interface with the KNX system, which is standardised OSI-based communications protocol, which allows the lights to be monitored by the Building Management System (BMS). I have advised the principal contractor (Dyer & Butler) to employ Schneider Electric as a subcontractor to commission the new DALI system due to their specialist expertise in this area.

Constraints

Operations. The CHSS facility is operational during working hours, therefore all works must be undertaken at night between 1130-0430 hrs. This leaves a very short window of opportunity after allowing for set-up and clear-up time. I am therefore working closely with the contractor to maximise efficiency by planning how the work will be sequenced and the methods that will be used.

Access. I have confirmed that a scissor lift can be used to access the lights above the walkways. However, some lights are fitted above the automatic, multi-directional conveyor. This system will need to be isolated to ensure that it will not operate while the work is being done. I considered the possibility of laying plywood panels over the conveyors to provide a stable surface for a scaffold access platform. However, this would necessitate the removal of the guardrails which would have been time consuming and further reduce the working window. After considering the size of the manoeuvring space available and the height of the guard around the conveyor, I identified a suitable MEWP for this application. A video of the Nifty Heightrider 12 is included below together with its capabilities. I advised the contractor to hire this equipment to test its suitability during the pre-works survey.

Stakeholder Engagement

There are various stakeholders involved in this project as show below:

- Contractors. I have established a good relationship with the contractors (Dyer & Butler Electrical and Schneider Electric) to refine the methodology and confirm the alterations that will be required to the wiring system.

- Suppliers. The lighting suppliers have assisted with the process of selecting the appropriate luminaires to ensure compatibility and provided the data to enable me to undertake a lux assessment.

- Assurance. Prior to commencing works, I must gain approval from the Chief Electrical Engineer who provides technical assurance of new installations / modifications to the electrical systems.

- Safety. All works at Heathrow require a necessary work permits and authorisation to proceed, which can involve a protracted process – but this is essential to de-conflict works with other projects. In addition, this work will require electrical switchboards to be isolated which must be performed by a nominated Authorised Persons via the Airport Operations Centre in accordance with the HAL Electrical Safety Rules.

- Customer. It will also be essential to maintain a continuous dialogue with BA to ensure this work does not affect operations. I will also need to coordinate with them to ensure the baggage lanes are clear each evening, to facilitate access to the lights and avoid the potential for delays and compensation events.

Financial Appraisal

Based on my analysis of the power and operating times of the existing lights, the current system consumes a total of 212,000 kWh per year. Heathrow Airport currently pays a special rate of 9.47 pence per kWh. Therefore, the existing system costs just over £20k per year to run.

By replacing the existing lights with LED equivalents and optimising the control system with PIR sensors and upgraded DALI gateways, the power consumption of the new system is expected to be reduced to 60,000 kWh. The cost to light the facility will therefore reduce to £5.7k per year, which will deliver annual savings of £14.3k.

Taking account of the costs for new luminaires, DALI gateways and installation fees, the final budget for this project has been estimated at just under £50k. Therefore, based on energy savings alone this project is expected to deliver a payback period of 3.5 years.

Thanks Sami for a very detailed blog, Mark will be well pleased.