West Gate Tunnel Project – site update

Just a quick blog to give an update on what is going on on my site at the moment as I head towards the culmination of my Ph 2 attachment.

As a reminder I am employed in the engineering team delivering the Northern Portal cut and cover structure in Melbourne from which two 16m dia TBMs will be launched early next year.

1st TBM following factory acceptance (manufactured across Europe and China)

We have finally got rid of the dirty and messy piling sub contractor on site, which has opened up some real estate and allowed the installation of the temporary propping system to begin in earnest. The planning and installation of the temporary propping system has been my primary area of responsiblity and so far we have installed five 40m props across the excavation, which has allowed us to start excavating beneath “roof level”

Having initially opted to use 35T excavators within the excavation, these have quickly been swapped out for 16T machines, due to slow productivity as a result of the machines getting bogged and the confined nature of the work area beneath the props.

Having initially opted to use 35T excavators within the excavation, these have quickly been swapped out for 16T machines, due to slow productivity as a result of the machines getting bogged and the confined nature of the work area beneath the props.

16T excavators working beneath props

Due to hold ups in the piling works as well as changes to the design and sequencing of works (we are currently constructing using a pre-IFC design) a lot of my time is being spent managing the logistics of receiving thousands of tons of steel on site (not necessarily in quite the required order) and ensuring the sub-contractors are kept abreast of design changes and constructing to the latest design.

One of many deliveries arriving on site

During installation of first props

During the prop installation, strain gauges are being fitted to a number of props, and settlement monitoring stations have been installed around the box, as well as prisms on the capping beam to detect any movement throughout the works.

Strain gauge installation

The data collected from these systems is monitored daily and trigger levels have been prescribed to provide alerts should unexpected movement or stresses in the props be detected. We have to submit a new permit to excavate every 24hrs which takes into account the information collected through our monitoring program.

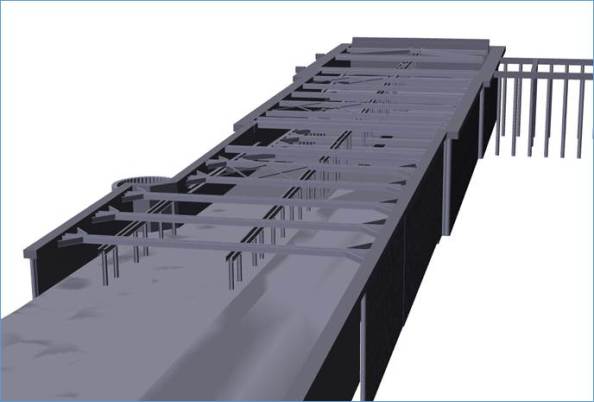

The model below gives an indication of what the portal will look like once all three level of propping have been installed.

The TBMs are arriving in February and by that point we need to have reached full depth, poured the base slab and removed the second and third level of props, so it’s a busy run up to Christmas….

All looks BIG!

1. Have you had any alarm bells go off yet with the strain gauges? What is the trigger limit?

2. Is the TW steel all bespoke? Who designs all the connections for your TW steel? The photos suggest much of this is pre-bolted before shipped to site in the ISOs – that right?

A nice blog and I hope it encourages your contemporaries. I cannot recall less blog activity .

These look like fabricated props with intermediate vertical supports

I have not seen anything quite like these; they are lacing hot rolled open section together. I’d have thought CHS would have done the same job.

The white shroud is to limit the effect of temperature rise

The gauges you show are vibrating wire strain gauges. A bit strange; On the steel itself it is cheaper to use bonded gauges and VWSG are usu allay used when you have a strain problem that includes the possibility of body movement ( ie movement across the joints that you show in the same picture) . I gauges Westminster bridge back in the 90’s and we loaded it with military water bags which we filled with Thames water . We saw little strain on the steel components and all the strain between components. I wonder…

Joe in answer to your questions;

1. No alarms yet. The strain gauges allow us to detect abnormal loads being experienced by the pile walls and the alarm level has been set at 25% higher than the expected load (based on soil profile and GWL). At 20% we get an amber warning and requires reconsideration of the design. The strain gauges also monitor the steel temperature and alarm if the steel reaches 35 deg C. At this point we have to initiate our high tech cooling system which consists of a garden soaker hose run across the props which will discharge water onto the white geofab. As John mentioned the geofab is to mitigate the heating of the props.

As a side note and possibly related to john’s comment on the strain gauges above, one of the issues that was mentioned by the I&M team is distinguishing between loading of the props and temperature effects affecting the steel, i.e expansion and contraction. (we’ve already noticed from bolts tensions that this is significant).

2. No the steel is a proprietary system which has been shipped over from Singapore (company called Yongnam). They are also supplying Glynn’s project actually. It is essentially a meccano set to be put together on site; the components just need to get bolted/welded together. And they get re-used, so we will return a lot of the pieces once we are done on the project to get re-furbed and shipped out somewhere else.