Archive

Pre-setting and Jacking

I have elbowed my way into the team that have been deciding on how to ensure that the design levels will be within tolerance in the finished state and remain within the movement and tolerance specifications as per the NSSS, as well as determining how to optimise this process. This is to be done through pre-setting baseplates and connections and jacking up columns a particular stages.

Within this team, which includes BHL designers, myself and the Mace project engineer, we discussed how to cater for the uncertainties inherent in designing for movement and the change in construction methodology will impact on the pre-set strategy. The the various causes of movement considered are:

Foundation settlement

Column shortening

Elastic elongation of connections

Deflection in beams and trusses

The pre-sets resulting from column shortening are to be accommodated by adding packing plates to splice and base plate locations. Foundation settlement was accounted for by elevating the columns with base packs on the single piles and by elevating the steel comb-cap pile caps.

Deflection of level 5 transfer deck trusses. The original plan was:

- Install Truss with pre-camber to accommodate self-weight of frame above, SDL of frame above and cladding above.

- Construct Levels 6 and 7 (including slabs).

- Jack between transfer truss and level 6 to push levels 6 and 7 back up to level

- Construct Levels 8 and 9 (including slabs).

- Jack between transfer truss and level 6 to push levels 6, 7, 8 and 9 back up to level

- Construct Levels 10 and 11 (including slabs).

- Jack between transfer truss and level 6 to push levels 6, to 11 back up to level

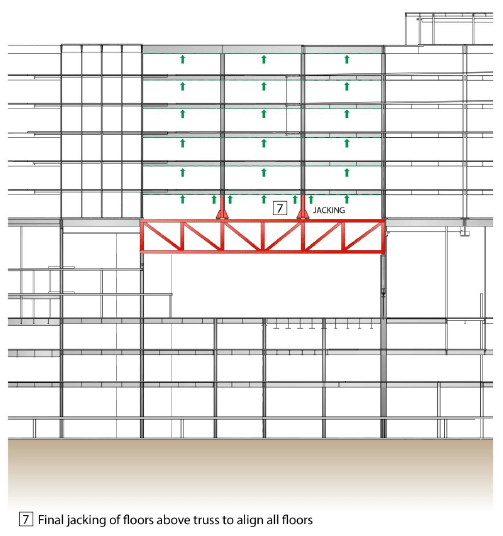

This is illustrated below:

This incremental jacking aimed to avoid high stress build ups in slabs. However it is a very time consuming process so we instructed to BHL carry out further, more in depth analysis with a view to simplifying the process. This showed that the expected dead load deflection of the transfer trusses is around 20mm, which is significantly reduced from the potential movement allowed for during the preparation of their original report and which the slabs would be able to withstand. As a result we have updated the method to install pre-sets at level 5 and jacking is planned only as a mitigation measure as part of an observational method that would likely occur when slabs at all levels are installed as per image below.

A I will explain under the next title, the steel handover level at L5 will be somewhere between design level and full L5 elevated level. This value and level must be calculated to determine the handover level for level 5 and all other levels above and supported off level 5.

So we need to come up with a plan of monitoring the deflection to ensure that it is as per the designers’ expectations. To do this I will survey the levels of L5 connections before they have any load in them, i.e before steel is erected and again when fully loaded. This will show if the trusses are deflecting as expected. If movements stay within the tolerances of the levels predicted by the designer then no jacking will be required. If the movement at level is not as predicted i.e. the level 5 trusses move more or less than expected, the columns will be jacked at level 5 and lifted, once disconnected from the trusses the base shims will be added to or removed to lift or drop the structure accordingly.

Settlement due to altered construction sequence.

An alteration to the programme involved speeding up pouring of slabs at lower levels, this meant that there would be higher loads earlier on, with associated settlements, deflections and elastic shortening.

The mitigating jacking method was based on the optimised and instructed construction sequence agreed at the time the construction analysis was carried out. It was expected only two levels of slabs would be poured at the time steel erection commenced above L5. With this amount of fabric in place the designers believed that the fabricated pre-set would not have dropped significantly. This allowed us to confirm that handover levels would be level 5 design level + full pre-set. However the changes meant that the level would be somewhere between design level and level 5 elevated level at level 5 handover.

We need to know what level to build the steel to above level 5, taking account of the movement that will occur earlier than expected, in order to know if it is within tolerance. To accommodate this I have collated the as built survey levels of column base plates, and have organised a survey to take place again when all floors have been poured up to level 5. This will show the amount of settlement that has actually occurred. The steel supporting the slabs above level 5 should be set at level = design level + pre-set – actual movement below level 5.