Archive

A Gantry Crane Bridge Too Far?

I recently had the pleasure of a week of night shift on my project (fortunately it will be my only one), during which I was responsible for overseeing the installation of the first half of a 90T beam on which a gantry crane will run to lift sections of the Tunnel Boring Machine (TBM) from the surface into the portal structure prior to launch.

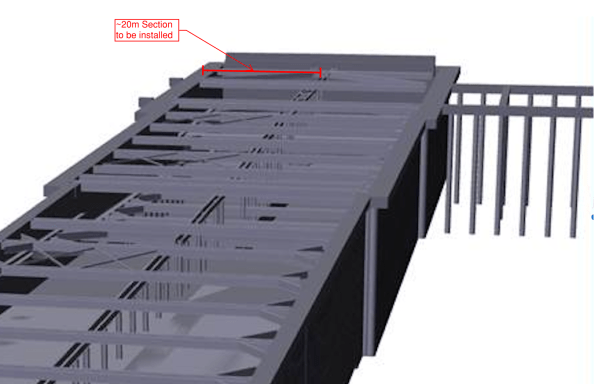

Fig 1. Highlighted gantry crane section

I had the night before been thrown a hospital pass and asked to install the bearing plate for the beam which sits in a recess in the capping beam, but that’s another story and it did eventually go in, see Fig. 2 below.

Fig 2. Installation of bearing plate

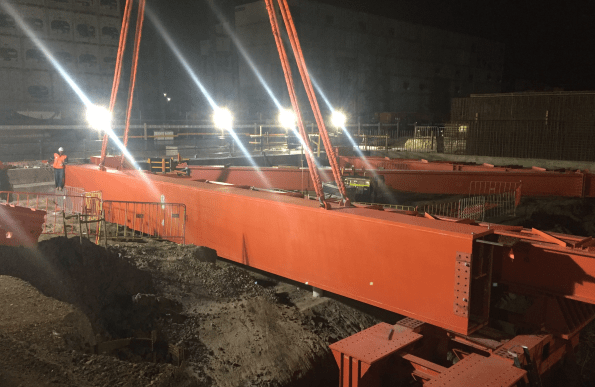

The installation of the gantry crane beam was quite simple, as you can see from the following photos, and the whole operation went quite smoothly;

Fig. 3 Gantry crane beam install

As part of our other works the crew were also busy prepping the bearing plate on the opposite capping beam and the second section of gantry crane beam was due to be installed the following day, once our high early strength (HES) grout had gained sufficient strength. I decided to do a couple of check measurements to see exactly how the second beam would sit and to make sure we installed the bearing plate correctly. I knew from the drawings that we were looking at around 80mm of clearance from the back of the capping beam recess, but my initial tape measurements suggested it was more like 270mm. I managed to grab the surveyors before the end of their shift and they confirmed my measurements.

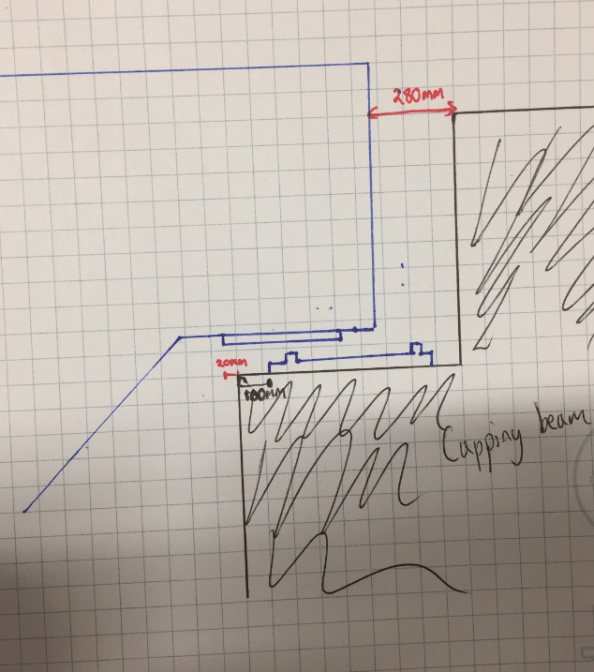

Having had a discussion with the foreman, and mindful that there is a risk associated with every lift, we decided to do a dummy run of installing the second beam to see exactly how it would be positioned in relation to the capping beam and the bearing plate. Having taken some photos when the beam was flush against the first section, it was evident that the “shoe” on the bottom of the gantry beam extended some 20mm beyond the edge of the capping beam, 195mm short of where it needed to sit on the bearing plate as outlined below.

Fig 6. Location of beam in relation to capping beam recess and bearing plate

This news was not very well received in the morning and the issue appears to be the result of the the gantry beam design not being reconciled with the wider cut and cover design, though the senior project engineers are being a bit cagey with the information on this…

Clearly some remediation works is required and I suggest there might be two ways forward;

- Remediate the capping beam.

- Break back the concrete in and around the recess.

- Tie in to the reinforcement and extend the capping slightly to give enough bearing for the gantry beam.

- Fabricate an intermediate section of gantry beam.

- Install the gantry beam so that it has the necessary bearing on the existing capping beam.

- Get an intermediate section fabricated to fill the gap between beams. (a rail will run on top of the beams so potentially a ~200mm gap not too hard to bridge?)

- Get new splice plates fabricated to extend across the gap in the beams

(Note: the design of the bearing plate means that relocating the one already installed would not be sufficient to fix the problem)

My initial thoughts are that to remediate the capping beam would be too complicated with potential issues due to the fact that the load on the beam may be supported partly on a cantilever and not transferred through the capping beam directly onto the piles below.

Fabricating an intermediary section with new splice plates seems like it might be a more viable option.

Thoughts from the wider forum?

The Chosen Solution

So in the end despite my cynicism, it would appear that the error in fabrication length of the gantry beam was not related to the engineering team and the blame lies with the steel fabricator in Singapore. The team did not want to draw attention to the issue so that a speedy resolution could be found on site with the upper echelons of the project wading in. It was decided that the most effective way to resolve the issue was to make changes to each of the bearing plate to allow the “boot” of the gantry beam to fit. The side already installed had fabrication work done on site , while the other was sent away to a worshop;

You’ll see from the image above that the front edge of the recessed plate was removed and an additional section of steel welded to the plate to bring it out level with the front edge of the capping beam. Both gantry beams have now been installed and at the headwall the excavation has reached level 2 of the props so waler brackets and walers beams are about to be installed. With only 2 weeks until the site closes for Christmas, the excavation will not reach base slab level as hoped but the engineering team are being driven hard to deliver. This is my last day on site, so unfortunately I won’t see level 2 going in.