Archive

Plunging within an existing building

Quick blog for interest as seems to be something that isn’t done particularly often.

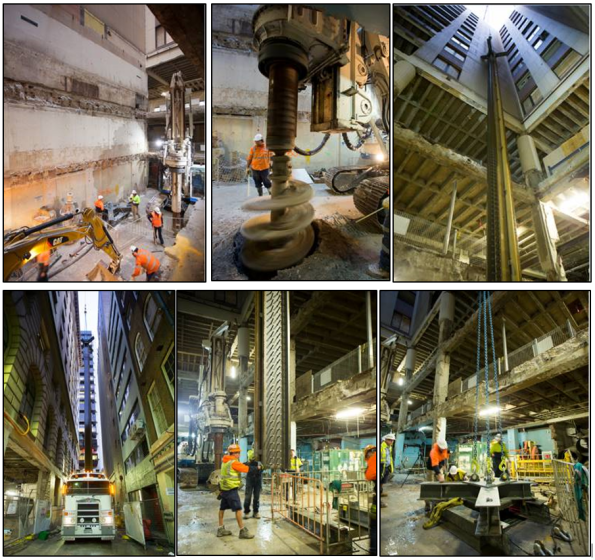

Shell House facade is to be retained (previous blog (‘loads of temporary steel’) explains the retention structure). I was asked how the plunge columns were constructed prior to demolition. Here is how it was done:

- Entrance from Wynyard lane increased and slab demolished to allow access for rig to drive in and down the ramp to basement level.

- Demolition of two slabs to allow access for lift in of columns (existing void from L1 up (see 1st and 2nd photo)).

- 21m plunge columns constructed.

- RC crane base cast on top of the 4 plunge columns.

- Stability core and retention system built from crane base.

- Crane tower constructed within stability core.

Figure 1 – Plunge Column Construction Photos

Figure 1 – Plunge Column Construction Photos

Trying to avoid skill fade. Trying.

I finished the PET Cse (Civil) in 2016 and subsequently found a reasonable amount of Attribute 1 & 2 ‘stuff’ in my time as an STRE 2IC to try and stay competent. You may recall from your visit to Chilwell a few months back, I mentioned the need to actively seek to find faults in Clk Wks work, firstly to ensure that what is designed won’t fall over and kill horse riders in Cyprus, but from a selfish perspective, to avoid the dreaded ‘skill fade’ everybody uses as an excuse to palm stuff off to Reservists in Arup.

Anyway, I am now employed as one of two Infra Requirements desk officers in JFSp (ME), looking after Infra across the entire Broader Middle East. Yesterday I was walking around TAJI (Iraq) and noticed this:

T-Wall on the piss (coincidentally missing a tie)

Surface water and drainage ditch filling up

12ft, 6 ton dominoes. No end anchorage to resist anticlockwise rotation.

Some idiot tempting fate. Note the rounding of the base reduces the surface area, increasing edge stresses.

Someone, in their infinite wisdom, has decided that they want a cam net to provide shade in the car park. The net is to be draped over the top of the 12 x T-Walls which are arranged in 2 x rows of dominoes, connected to lifting eyes at the tops by ratchet straps which serve as ties. Yip, ratchet straps. There are a couple of ‘ties’ missing, but the alarm bell sounds something like ‘where are the anchor points at either end of this arrangement?’. My point being that when 1 goes, more will follow.

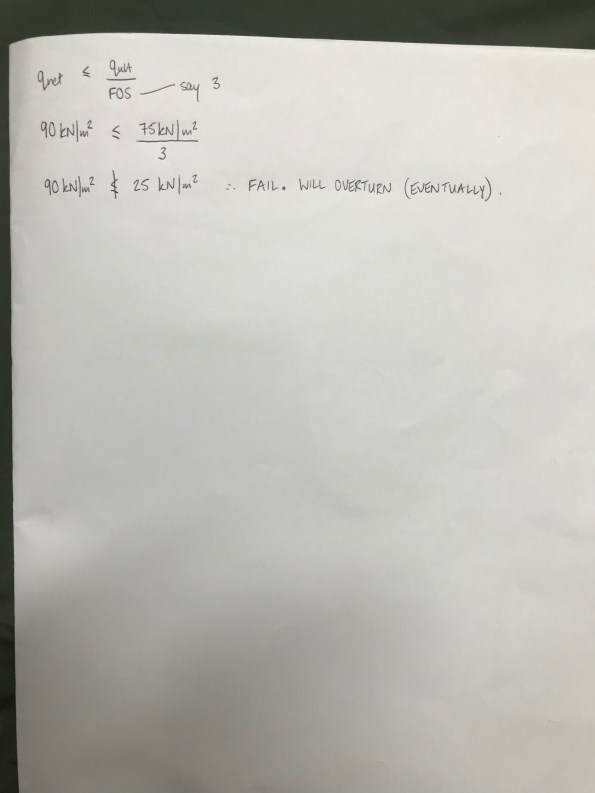

I sheepishly present my ‘back of an envelope’ calcs below. No ground investigation exists, but it is very obviously clay (bordering on impermeable) judging by the pools of water all over camp. I conservatively assess it to be a soft to firm clay and assume a GBC of 75 kPa (Cobb’s Structural Engineers Pocket Book p100). No wind data to hand so I’ve used a notional 1 kPa which translates to a force of 6kN acting at 2m, applying a 12kNm moment at the base.

A few limitations/ assumptions (risk) in my assessment:

- I don’t actually know the shear strength of the porridge clay.

- I don’t have any wind data, made that up too.

- My section modulus is not perfect.

- I do everything conservatively because I want to prove this fails because it just looks wrong.

Feel free to rip me to shreds on the calcs. The important thing here is that there is already evidence of the T-Wall overturning so calcs aren’t actually required to raise the risk to PJHQ (although they might give me some credibility when dealing with a flat head who likes cam nets).

Nonetheless, I reckon this T-wall is going to come down like Saddam Hussein’s statue. Hope this gives you an idea of the sort of ‘stuff’ you can do to try and maintain competency when you have finished the course.

H=0.5V=Sliding Modules?!

Company tour over, I was asked to design the spread foundations (not shallow) for a two-storey temporary lecture theatre facility for Swansea University. This is as their development strategy is 3 years behind programme. Albeit indirectly thesis related, it allowed me to refresh my soil classification and foundation knowledge as well as gain some pre-phase 3 calculation and design practice.

Foundation Design

This project is to be the first installation of their new RapidPlan product – a proprietary hot rolled steel framed box of 12×3.6×3.6m. Figure 1 shows the arrangement of a module (black box running left to right) and duplicated top to bottom. It will be 50mx36m. The different colour dots denote different column loads. There will be 83 foundation pads so standardisation, like the modules, is essential for design cost reduction and ease of construction. The aim is not to use deep foundations as the other tenderers are all proposing so to be very competitive.

Figure 1 – Arrangement and column loads (measurements in mm)

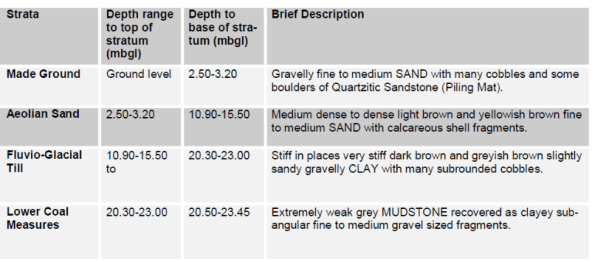

The Site & Ground

The site is reclaimed from the sea (100m) and exposed so peak wind velocity (qp) and shape factors (cs) are high. The ground has 100mm topsoil, then a 3m engineered piling mat (with sand fill) (which is strong – Plate Load Test to 365kN/m2 with only 1.25mm settlement) then medium dense sand down to 12metres. There is loads of PLTs, boreholes, trial pit and CPT data available. The piling mat is assessed as φ’=35o and SAND at 32 o. The ground is granular so has been treated as drained and is young so normally consolidated.

Figure 2 – Summary of Ground Conditions (WSP, 2013)

The ground water level is relatively static at 2.5m depth so is at the piling mat and sand boundary. This significantly reduces the strength of the sand (ϒ’=ϒsat– ϒdry) below that of the stiffer piling mat. Having initially used the presumed bearing capacity check (qp) from Method 2(EC7) the ground was deemed capable.

Loads

On lightweight modular structures live loads are often greater than live loads i.e. Qk>Gk. Column loads were issued by their structural engineers Fairhurst (used as a Phase 3 company before). This enabled limit state checks by Method 1. The 6no vertical loads, Figure 1, ranged from 64-440kN unfactored/service. Not a problem. However, the worst vertical to horizontal ratio at the base of the edge columns (blue dots) is 48%! I remember John saying that if H>0.1V then be worried, don’t get involved and see a specialist! Enter PET student…

Design Considerations

Figure 3 – Free body diagram

– A 1x1x1m concrete pad or paving slab is traditionally used to avoid using rebar and rarely with holding down bolts. A pad over strip foundation is planned because if L>B the zone of influence for bearing capacity increases from B to 3B deep.

– Each module uses moment connections (it’s a box that won’t tip over) so sliding is the module’s largest risk. Globally this means transferring 0.5H to the other longitudinal/transverse base. The column to pad connections are pinned.

– The sliding resistance (Rd only) from concrete to ground at 155kN/pad suffice compared to 64.5kN (0.5H). Passive resistance (Rpd) was not considered necessary at this stage.

Constraints

– It’s to have a 5-7year design life.

– The governing level is the FFL at the northern edge for level access. There is a 400mm level difference from northern to southern pads.

– The bases are to be at the minimum 450mm depth to prevent frost heave.

– I don’t want to go any wider or deeper than 1.5m as the saturated sand comes into play reducing GBC and increasing the risk of immediate (ρi) & differential (δ) settlement. Albeit the modules can manage 10mm.

Design Development

With the combined vertical and horizontal actions the two options considered (based on the site levels) are:

| Maximum pad thickness (1x1x1.5m) | Minimum pad thickness (1.5×1.5×0.5m) |

| + Increases surcharge load (qo) and so GBC | – Minimum surcharge load (qo) so GBC reduced |

| + Increases P with concrete self weight | – Decrease of P so GBC reduced |

| + Increases Rd and engages Rpd. | – Minimal sliding resistance (Rpd = 0) |

| – But increases moment (MH) & relies on Rpd | + Reduced moment (MH) |

| – Minimum depth of strong piling mat | + Increased depth of strong and stiff pile mat |

| – Increased concrete cost (3.4x) and installation | + Reduced installation time and cost |

| Risk is strength and settlement in the ground | Risk taken on effects of actions i.e. sliding |

Table 1 – Design options

I’ve used Geo5 to verify my ULS workings, but need to complete the SLS settlement checks which may be the determining factor. I have a preferred option and am hoping this forum will help confirm or quell my intentions. Especially as I’m still unsure about John’s H>0.1V… Any ideas? Or had similar issues? Or have I just slid you over the edge?

Realistically whilst there is an ideal engineering solution I am seeing first hand that the chosen solution is likely to be economically driven.

Phase 2.5 & Active Buildings

I am two weeks into my self-titled Phase 2.5 – a three week attachment with a privately owned company specialising in offsite modular manufacture and construction. This is as they, Wernick Buildings, are interested in developing a rapid foundation assessment method for low-rise structures i.e. my thesis. Essentially looking at quicker ways of assessing ground bearing capacity and settlement using a Dynamic Probing Light (DPL) (EN ISO 22476-2), a small and man-handle-able SPT (Standard Penetration Test). SPT is the energy required i.e. number of measured blows (N), to penetrate 300mm with a 63.5kg mass. For DPL it is 100mm with a 10kg mass. There is currently no widely accepted method to correlate the two methods. Obviously this has both civilian and military applications, hence the interest. However, after a tour of their factory and look around their main products/modules I was taken to their latest project, the UKs first energy positive building aka…

An Active Building producing Micro Energy

Figure 1 – ‘The Active Building Centre’s vision (centre) is to transform the UK construction and energy sectors, through the deployment of Active buildings powered by the sun, creating energy resilient communities, and significantly contributing to electric vehicle and decarbonisation targets.’

The Active Building Centre at Swansea University, is a new pan-UK university research initiative by SPECIFIC (funded by Innovate UK & EU circa £36m). It is to ‘reduce the cost and commercialise energy generation and storage components in buildings’ i.e. turn buildings into decentralised micro power stations. The ABC stored 29kWh and exported 47kWh back to the grid on the first day it was opened. This is the first building to achieve an A+ negative value on its EPC. It recycles its own energy emissions – what Building Emission Rate (BER)?! (Bld Regs Part L2A).

Figure 2 – The Active Building Centre’s live dashboard and EPC

A very apt concept when international carbon emissions are on the increase again after four years and on the first (actually second) day of the UN climate change conference COP24 in Katowice, Poland. Has Swansea secured a small chapter in the future of climate change?

True or False – Does this sit within the concept presented by Jason for his CI’s Essay on ‘energy storage in a non-fossil fuel national grid’…?