Archive

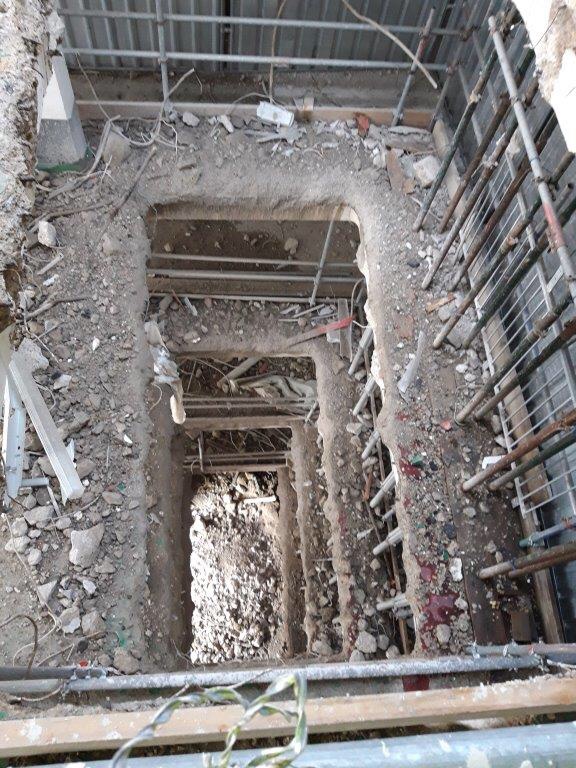

Red Car Park Demolition

I have just started phase 2 on a demolition job for a car park on the Victoria square redevelopment in Woking. I realise that we don’t really cover demolition in phase 1 so thought I would share some photos and information on how they are doing it as a general interest piece.

The car park has 3 cores, the South and East have a lift and staircase while the West just a staircase. The methodology is simple, the excavators work in pairs (one pecking and one munching) to remove the slab. They always work on floor up to prevent the support underneath being undermined. There was a structural load test conducted of the slab and it was determined that 1 x 13t piece of plant can stay in one structural bay with 1.5t of rubble around it to prevent collapse.

The lift cores have a concrete slab roof which is removed by a remote control pecker for H&S reasons.

When the workers start a new floor the priority is the parapet wall and then the 2m cantilever at the edge of each floor. There is a demarcation to ensure no plant is to cross onto the cantilever

All rubble is collected by small BOBCAT shovel shifters and dropped down a shoot to the ground floor. This shoot is closely protected to prevent any labourer wondering close by.

The plant works in a methodical order, much like painting a floor in your house to ensure they don’t leave themselves trapped on a level. The rubble is then removed by a 20t excavator on street level into skips that are removed daily.

There have been issues this week with high winds ripping the protective sheeting off the scaffold which means demolition can’t take place and today the temporary water pipe used for dust suppression was broken when rubble fell down the lift shaft from the slab above and broke it in two.

Plenty of engineering challenges to come as the client seeks to keep the adjoining shopping centre open while demolishing the concrete frame around it.

Any interested questions regarding demolition send my way.

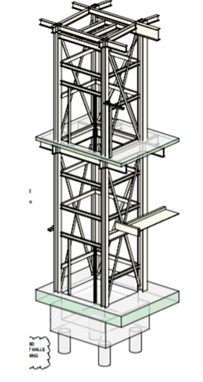

Trimming your piles

Hello all, first blog post from me (Al Bramson PET(C) 66). For those who don’t know I’m currently working at Gatwick Airport on the client side as a Project Engineer. The project I’m currently assigned to is the construction of a new passenger departure building to accommodate the A380, the big double decker plane. I’ve been inspecting some of the groundworks that has begun for this project. In particular, the pile foundations for a lift core that runs vertically through the centre of the building (see Figure 1). Kier are the subcontractor for the project and they have subcontracted the ground works to Oliver Connell.

Before Oliver Connell were to install the reinforcement cage and cast the lift pit they had left the pile reinforcement exposed (Figure 2). When I returned back to site I noticed that they had cut the pile reinforcement at the top of the pile, about 75mm above the bottom of the pile cap level. I foolishly didn’t take any photos (lesson: take lots of photos!). This cutting of rebar didn’t seem right to me as I think that there should be some reinforcement to anchor the pile to the pile cap. However, as the foundation seems to be in compression only, maybe this is not such a huge issue? The pile cap is about 1.5m deep so there is no risk of uplift as far as I can tell. Also the reinforcement cage for this is rather dense so I think they cut the pile reinforcement in order to fit the cage on top of the pile. Also possibly to save money on purchasing rebar couplers (as per Figure 4) which I understand can be collectively quite expensive.

The Senior Project Engineer seems to believe that they should have bent the rebar and definitely not cut. I checked the project drawings and they are not clear on this. I would think that the rebar would be bent if there were moments on the structure (like with a column), but the moment caused by wind loading is relatively small (bearing in mind it’s an internal lift structure). I’ve tried to research myself using the IStructE manuals with no luck. Anyone able to offer some advice?