Trimming your piles

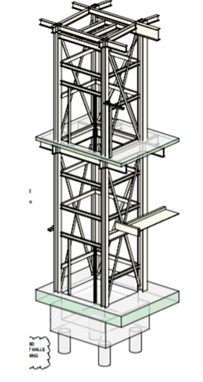

Hello all, first blog post from me (Al Bramson PET(C) 66). For those who don’t know I’m currently working at Gatwick Airport on the client side as a Project Engineer. The project I’m currently assigned to is the construction of a new passenger departure building to accommodate the A380, the big double decker plane. I’ve been inspecting some of the groundworks that has begun for this project. In particular, the pile foundations for a lift core that runs vertically through the centre of the building (see Figure 1). Kier are the subcontractor for the project and they have subcontracted the ground works to Oliver Connell.

Before Oliver Connell were to install the reinforcement cage and cast the lift pit they had left the pile reinforcement exposed (Figure 2). When I returned back to site I noticed that they had cut the pile reinforcement at the top of the pile, about 75mm above the bottom of the pile cap level. I foolishly didn’t take any photos (lesson: take lots of photos!). This cutting of rebar didn’t seem right to me as I think that there should be some reinforcement to anchor the pile to the pile cap. However, as the foundation seems to be in compression only, maybe this is not such a huge issue? The pile cap is about 1.5m deep so there is no risk of uplift as far as I can tell. Also the reinforcement cage for this is rather dense so I think they cut the pile reinforcement in order to fit the cage on top of the pile. Also possibly to save money on purchasing rebar couplers (as per Figure 4) which I understand can be collectively quite expensive.

The Senior Project Engineer seems to believe that they should have bent the rebar and definitely not cut. I checked the project drawings and they are not clear on this. I would think that the rebar would be bent if there were moments on the structure (like with a column), but the moment caused by wind loading is relatively small (bearing in mind it’s an internal lift structure). I’ve tried to research myself using the IStructE manuals with no luck. Anyone able to offer some advice?

Nice one Al. If the principle actions on this are the self weight of the lift tower it is possible that you are looking at a pure compression connection. The slightest out of true will introduce horizontal gravity effects and shear so what exactly is all that reinforcement for? Might it be that this is the stability core we are looking at and there is substantial transfer of lateral loads going on? Might there be a moment applied about the base? You need to step back and look at the whole structure not just parts of it and have think about how it is all working. I refuse to believe that there are not reinforcement drawings and schedules for this. Pity about the photos but if you order opening up you’ll get them then!

Richard, having had another look I did eventually manage to find the drawings that show the anchor detail. The project has just moved to a new file sharing software system this month so I’m still getting used to it! The pile caps should indeed have had anchors. Having looked at the structural calculations for the original design it looks like the lateral loads are resisted by cross bracing (not surprising given the building is only two storeys high).

The result of this is that the issue has gone back to the designer (Pascall & Watson) awaiting their response. Work has stopped on this foundation until the issue is resolved.

So the structure fixed to this pile cap is designed to carry lateral loads to ground through bracing. When it meets the ground it does so at the pile cap i.e. the pile cap has to resist a lateral action. There is also an overturning moment resisted by the piles acting as a couple i.e. compression and tension, which if not exceeded by vertical actions will result in tension in the pile. You might sketch this as a model and see if it makes sense. This is an excellent piece to carry forwards to CPR because it allows you to explain some fundamental principles in a relatively straightforward situation and sketch free body diagrams, which reviewers love! It also leads into contract and commercial via a practical and technical discussion. Gift horse! Remember this and we’ll discuss in 12 months!

Hi Al,

A good spot, that is a definite boo-boo! The top of a pile should be “embedded” 75 mm into the pile cap so maybe that’s where the 75mm came from, but any RC in compression should have the rebar correctly anchored. Have a look at table 2 in the “How to design concrete structures to EC2” guide, I used this a lot on site to confirm that anchorage and lap lengths were correct. If they don’t want to pay for couplers then breaking out and lapping new bars is another option, but maybe not desirable as it takes longer and may be difficult to get a pecker in there.

There are four reasons for cages in piles:

a) To provide against uplift from swelling soil ( you seem to have Cordek formwork- what’s that for then?)

b) there is lateral loading causing associated bending moments in the shaft ( you have bracing in the lift core – what’s that for then?)

c) You are actually transferring a bending moment into the pile directly (let me know if you come across this – I haven’t….yet)

d) You are in soft or loose soil ( I’ve never really understood this but see the note on Execution Code later

e) To reinforce against accidental construction impacts ( you don’rt want a brittle pile head)

For a) and b) , possibly c) you’d need a lap length

For d) – I dunno

For e) You don’t need anythig

So when they decide you might ask …on what grounds

What I would urge … as if I hadn’t urged this enough is look in the execution code BS EN 1536: 1999 first