Arrival on the West Gate Tunnel Project

Having completed Phase 1 of the PET(C) I have successfully transitioned onto Phase 2, working for John Holland on the West Gate Tunnel Project (WGTP) in Melbourne Australia (a fantastic city with great weather, so far). I have now been in the site office for 2 weeks and think I have enough of an understanding of the broader project and my site to impart some of my findings and thoughts on this blog.

I apologise in advance for the length of the blog, but I think this is testament to the sheer scale of works involved!

West Gate Tunnel Project Overview

The Clients have formed a partnership between the Victorian State Government and Transurban, and have selected two contractors to deliver the A$6.7 billion (approx. £3.65billion) infrastructure project. These are CPB Contractors and John Holland (CPBJH JV) in a 50:50 joint venture. Major construction work started in early 2018 with the project scheduled to open to traffic in 2022.

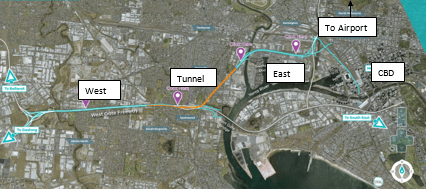

The project aims to deliver an alternative to the West Gate Bridge to the West of Melbourne’s city centre, close to the Central Business District, which currently caters for more than 200,000 vehicles a day, a very busy and congested route; having used this route for 2 weeks, in rush hour, I can certainly vouch for this.

The project involves building four more lanes on the West Gate Freeway, twin underground tunnels, a new bridge over the Maribyrnong River that links to an elevated road and a 14km Shared User Path (SUP). These three key areas have been split into three zones of interest; West, Tunnel and East.

Breakdown of WGTP Zones

West Zone: Construction of four additional lanes the West Gate Freeway.

Tunnel Zone – Construction of twin tunnels running north to south, linking the M1 west of the West Gate Bridge to the North of the CBD. These tunnels are 2.8km and 4km.

East Zone –This zone will see the construction of three bridges (one freeway and two joining slip roads) across the Maribyrnong River and an elevated freeway linking into the centre of the city. This is where I have been positioned.

East Zone

Testament to the sheer size of the project, the East Zone has been split into five subzones outlined below (remembering that this is one of three). I have been placed in subzone 401 (or the ‘Maribyrnong River Crossing and Mackenzie Road’ subzone’), which will see the construction of a four-lane bridge across the Maribyrnong River with two adjacent on/off ramps (both bridges in their own rights), a connecting bridge on the east bank between both slip roads and a raised SUP (approx. 5km of the total 14km being built).

My Role

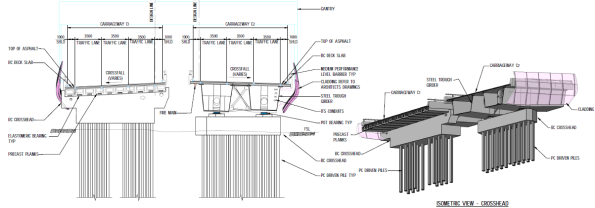

My official role within the project is as a Project Engineer working in the substructures team, of which my duties include: Planning of works, ensuring compliance with quality and procedures, monitoring safety and environmental controls and provide technical assistance to the Foreman and workforce. The task of the substructures team is to install all foundations, temporary works for the superstructure team and install all structures up to the point that the bridge decks can be installed (i.e. installation of bridge piers up to the bearings).

Example of Substructure Team’s Limit of Responsibility

Initial Thoughts and Risks

Driven preformed and bored cast-in-place piles are to be used for the foundations of the bridge, including 400mm square precast concrete piles for the sections of bridge located out of the Maribyrnong River, and steel tubular piles with reinforced concrete infill, to approx. half the depth of the pile (I believe this is for durability reasons over structural, i.e. susceptibility to corrosion of the steel tubes in the upper formations, but I hope to clarify this soon. This does make me think that there must be a method of transferring load from the RC to the steel tube at the point of RC stopping; I’m assuming through friction?), for the piers supporting the river crossing spans. Bored cast in place piles will be used for the SUP.

There have been many boreholes drilled along the alignments of each bridge as part of the GI, suggesting to me that CPBJH JV have considered ground conditions to be a key risk in the execution of these works. The GI appears to be comprehensive. Comparing the alignments, I could see that the ground changes dramatically on the East bank of the river between the three bridges. This rang alarms bells in my mind as the steel piles were clearly designed with the toe formation in the Lower Older Volcanics to achieve the required end bearing capacity. To understand how they plan to mitigate against the risk of the ground model being incorrect and the pile toe not reaching the required formation boundary, I consulted the geotechnical engineers subcontracted to design the piles who informed me that they have designed the piles 2m longer than the expected required depth for such a scenario.

Typical ‘In River Pier’ Piled Foundation

The precast piles, which are working as pile groups, are designed across the site with a toe depth that reaches formation in the Upper Volcanics formation. Again, there is clearly a risk here that these piles may not reach the required depth, based on the varying formation levels in the ground. It appears that the risk has been mitigated here by relying on the high number of boreholes conducted. I shall see how this manifests as the piling starts.

Typical ‘In Land Pier’ Precast Piled Foundation

From what I can understand, the leading factor for using driven piles across the whole project (not just 401) is the ability to limit soil excavation and disposal. When I first arrived at the area I could see vast piles of covered soil from previous excavation works. Intrigued by the reasoning for this I consulted the East Zone Manager, Alan Platt, who informed me that the soil across the whole site had been found to be contaminated and required specialist removal from site at a cost of approximately A$500 (if I remember correctly) per m³. This had not been picked up prior to the contract being agreed between the Client and CPBJH JV, with CPBJH JV unwilling to pay for the thousands of cubic metres required to be removed (clearly this would eat well into their profit margin). As it stands, from my understanding, the Client and CPBJH JV are working to find a solution to this through negotiation. I plan to dig (ignore the pun!) further into this to understand where the risk for such an event was held and how it could be avoided in the future.

In total, 738 piles are required for the permanent works alone. This does not consider for the temporary works piling, of which there is a lot; for example, 70 are required for temporary jetties alone (a whole other topic that I will look to discuss separately).

Looking at the bigger picture, it is estimated that more than 5000 piles are required for the WGTP. This led to the setup of a precast yard (something I plan on visiting soon), which will produce precast piles, bridge decks, super T’s and other precast elements. From the immense numbers of precast elements required, along with the relatively short timescale of roads opening in 2022 (not a single pile has yet been installed in the East Zone), I see procurement of precast elements as a key risk for the project and must be managed closely; piles require 14 days curing prior to delivery. It is my understanding that precast elements have not been poured for 401 yet, which makes me question our ability to begin piling precast piles on time; a quick bit of simple maths (i.e. counting days) makes this apparent. We shall see!

Summary

I have arrived on site just as site clearance and preparation has started. This has provided me with the much-needed time to understand the ‘bigger picture’ of the WGTP and the intricacies of my site (and get my head back into John Moran’s Lecture Notes!). Over the next couple of weeks, I intend on interrogating the contract in more detail to understand what is driving the project as well as how my site relates to the WGTP critical path. I look forward to ‘getting my boots dirty’ on site once the piling starts and to the challenges the lay ahead, of which I’m sure there will be plenty.

Hi Dan, great choice in coming to Melbourne. It is a fantastic place to live and as your blog shows, there is a lot of interesting construction being undertaken as part of the Victoria Big Build programme of works (https://bigbuild.vic.gov.au/). Just two quick comments ref the blog;

Firstly, we had exactly the same issues with contaminated spoil handling and there are a couple of key terms I found when talking about the geology of Melbourne; Coode Island silts, Melbourne Formation (MF1 = high strength rock) and Potential Acid Forming Rock (PAF). The existence of any of these on the alignment used to strike fear into the budget holders, as you have identified, they are expensive to remove from or to treat on site. However, Melbourne is pretty well set up to deal with this geology; for example there is a contractor that can make bricks out of some of the PAF. It is worth talking to the Enviro/Sustainability team and dig out the projects Contaminated Spoil Handling Plan, as this should describe the timelines and options for dealing with these materials as they are common in Melbourne construction. Regarding the dispute between the Client and the Contractor, I would be surprised if an experienced contractor in Melbourne wasn’t aware of the risk of uncovering contaminated soils, a quick review of the Clients GI should have highlighted the risks? Maybe the quantity being excavated is much higher than that priced during the tender?

Secondly, the risk you identified regarding the founding of the pile in the competent strata. A common risk in piling and one way of mitigating it is to extend the length of the pile. However, obviously additional length of pile requires additional time and resources (particularly with bored piles). In my experience, our piling contractor would look for ways to reduce the drilling depth wherever possible (especially when they started to slip behind programme; the CFMEU don’t allow work in the rain or +35deg). We were in MF1, high strength rock, which as John Moran would say, is only a risk when you are trying to excavate it! A second way of mitigating this risk is oversight of the piling operation by an experienced (in Melbourne geology) geotechnical engineer, these inspections should be hold points on the ITP anyway. The specifications for piling in Melbourne are very strict on this inspection regime. On the Melbourne Metro Project we used VicRoads Standards – if I remember rightly, the 600 series covers bridgeworks and piling. As a government funded project, I would assume you are using VicRoads standards also, but worth checking. We were able to reduce the length of a number of our piles on the sign off from the geotechnical engineer that we had reached the competent strata before the designed toe level. You can’t always reduce length this way due to other construction factors, but worth considering.

Glyn, lots of knowledge there! I’ll be tapping into some of that over the coming weeks I’m sure. I’ve done some reading into the various soil foundations and have come to the same conclusion with regards to the Coode Island Silts. Unfortunately our alignments, as you can see in the pictures, are overlying this. We have some hot spot workshops coming up, so I should be able to tap into the enviro team on this.

I too was surprised by the removal issues of the contaminated soil. It would seem to me that, for such a large project, in such a well developed area, that this would have been a priced in risk, if a risk at all (considering a competent GI, and even just a desktop survey, would have picked this up all over). As mentioned, I’ll be looking to interrogate this over the coming weeks to try and understand what our position is, and if there was a mistake in the contract or not.

I’ll do some background reading into the two piling contractors being used to gain an understanding of their experience working in this area. We are using Vicroads 600 series; I’ve had the joy of printing these off and started familiarising myself with them. My initial understanding is that we will drive until pile refusal/design depth/formation achieved; something I am trying to understand at the moment.

With the inspection regime – we are conducing dynamic testing on all piles in the river for sure; they are transferring large loads into the lower volcanics, much higher than the loads in the precast piles. Was this something you/Auggy experienced? Or did you use a different method? It seems that the piling method chosen is largely due to the ability to conduct dynamic testing.

Thanks for the info! Standby for lots of questions!

Dan, a good project, and a biggy! A couple of thoughts from my perspective on the management of contaminated spoil.

Given that the west of Melbourne has a big industrial past, I think the issue of contamination across that whole area is a known risk. There is an initial GI report by Golders for the WGTP on the system and they had a whole document on the contamination risk if I remember correctly.

Managing spoil was/is clearly a big part of excavating the North Portal and though I wasn’t hugely involved in it, I picked up on a number of things. Firstly understanding of the different classification of contamination and what that material would look like was poor among the engineering team and the guys on site. This meant that early on material was being wrongly classified and either we were paying more to send clean spoil out as contaminated, or trucks were getting turned back from the tip with contaminated spoil we were sending out as clean. This was resolved by delivery of a number of toolbox talks to make sure the guys on site knew exactly what to look for so they could separate material appropriately. (one of the engineers produced a crib card for site with pictures and descriptions of the material we were expecting to encounter). The second step that was taken to better manage spoil was to maximise the fidelity of the classified areas. This meant more detailed engagement of the geotechnical engineers and environmental team, but allow us to reduce contaminated areas to hot-spots and minimise the contaminated spoil being disposed of. I’m not sure how practical this will be in the case of discrete pile groups, but it is possible that someone has been a bit liberal when classifying spoil as contaminated and worth a check.

Auggy, cheers for the comment! All great stuff.

I’m slightly confused as to why there is an issue in removing the soil if it was a clear requirement (i.e. not really a risk at all). As I’m sure you and Glyn will have seen, there are piles of covered soil along Footscray Road (and the local vicinity) that has been there for some time now, It seems to me that, if this was so obvious, it would have been pre planned and have been removed instantly; so this would indicate something isn’t right. I’ll keep looking into it when I get the chance.

That’s interesting about the guys on site misclassifying the soil, and clearly a risk (that might not have been picked up) that could cost dearly. I’ll have a chat with the senior PE here and see if the 401 risk register has picked that up. If not, we might be able to save ourselves some heartache down the road. out of interest, do you have the name/contact details of the geo engineer who facilitated this? (was it someone at DP by any chance?). As far as I;m aware, we do have a series of hot spots across the site, which are being managed; again, something I need to investigate (the list is getting longer and longer! haha)

Any tips about the site (it appears your site was about 200m from mine???) you have would be welcomed with open arms!

I’m at a stage now where I think I’m ready to start putting my analysis of some points I’ve picked up on to the area manager/senior PE … we shall see.

Good blog and nice thread gentlemen. It even reads like a competent technical discussion between engineers! W.r.t. the cased piles and cages, I suspect that the lower end is considered to be in pure compression so no real requirement for reinforcement, the upper is effectively reinforced by the casing but if that corrodes then you become reliant on installed reinforcement to deal with the issues JM discussed in his response to Al Bramson’s blog. There is no need to transfer between the cage and the tube, although this will happen automatically in bending.