Reflections from the other side of the world…

‘G’day mate’, ‘how you going?’, ‘too easy’ and Struth, it’s hot out here… (ok so that’s enough of the Australian slang from me). Welcome to the first blog post from me on the Batemans Bay Bridge Project. After less than 2 weeks on the project I’m still trying to get my head around the technical side of things so this post will give a project overview and summarise my initial observations.

Project Background

Like me, most of you won’t have heard of Batemans Bay before. Its a small town of about 11,000 people on the East Coast of Australia in New South Wales (see map). To get here you have either a 4 hour drive south from Sydney (170 miles) or a 2 hour (94 mile) drive east from Canberra. The town straddles both banks of the River Clyde with the A1 ‘the Princes highway’ between Sydney and Melbourne passing straight through the town. On the northern side of the town, the A1 meets the B52 ‘the Kings Highway’ which is the quickest route to Canberra and the Australian Capital Territory (ACT). As a result Batemans Bay has a lot of through traffic and has become a popular destination for the Canberra residents as it has the nearest beach.

Map showing Batemans Bay location

The existing road bridge connecting both sides of the river is an old 1950s steel truss bridge which supports a single carriageway. It has an unusual design incorporating a central vertical lifting span to maintain marine access upriver (see picture). With increased and heavier traffic flow along the A1, spiraling maintenance costs and congestion from bridge closures for marine access the client RMS (Roads and Maritime Services similar to Highways England) has decided to invest in a new bridge and associated junction upgrades. John Holland’s solution is a joint venture with VSL to deliver a 168 segment precast concrete box girder bridge under a Design and Construct Deed (D&C contract). This construction method was chosen to increase spans and reduce the number of piers following public consultation. An impression of the completed bridge is also shown below.

Existing Batemans Bay bridge

Impression of new bridge.

Further information can be found on the RMS website: https://www.rms.nsw.gov.au/projects/south-coast/batemans-bay-bridge/index.html

The delivery of the project is split into 4 overlapping phases:

Phase 1 – Design, enabling works and service diversions. This phase was due to end this month but has been extended by 3 months after additional works were added to the scope of works to ‘future-proof’ cross-river service capacity.

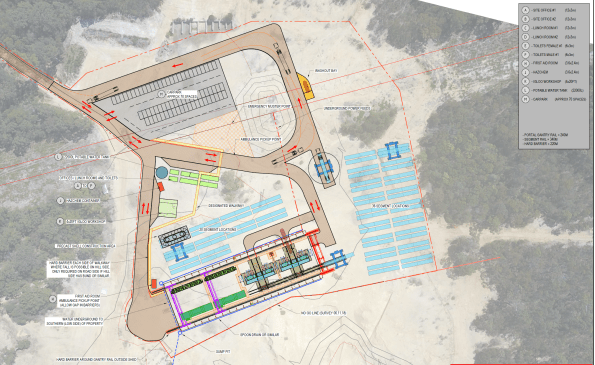

Phase 2 – Bridge construction. This phase is just getting underway. This week we started the establishment of the precast yard and commenced the first pier foundation pour. Initially, my job will be working as a Project Engineer to establish the precast yard bridge. This is a great opportunity to see a range of engineering including earthworks, piling, reinforced concrete, steel erection and gantry crane installation. Can you tell I’m excited about it?

Phase 3 – Junction upgrades. Elements of this phase will run concurrently with Phase 2. John Holland receives incentive bonuses for maintaining certain levels of traffic flow which will result in a staggered approach to the junction upgrades.

Phase 4 – Demolition and removal of the existing bridge including the removal of all substructure and foundations. Planning for this phase starts next year so if you fancy the job Ash Dale let me know and I’ll make sure your CV gets to the PM…

GA of proposed precast yard

Initial Observations

So what are my initial observations after 2 weeks in the office?

- Communication. The Australian construction industry and UK military both have their own slang:

– Slew cranes (mobile cranes).

– Franna cranes (not common in the UK but is used for small mobile lifting operations like a 35t TEREX or RTFL).

– FRP – Formwork, Reinforcement Pour (RC to you and me).

– Star posts (6′ pickets).

It’s definitely worth taking the time to check exactly what is meant by terms you are unfamiliar with to avoid confusion and misunderstanding. Google image search is also a great resource – it’s true, a picture paints a 1000 words and all that! We also have a French contingent from VSL as well as engineers from Asia, New Zealand and the UK. We all use the same technical language which aids communication regardless of the native tongue.

2. Commercial awareness. I’ve been surprised at how commercially involved the engineers are on site and was warned about this by the PM during my arrival chat. Here the engineers are responsible for planning/designing their work packages and resourcing them. For supply of materials this requires a minimum of 3 quotes and a purchase order. If services are required, a short form contract is needed resulting in a tender process. From my initial observations it seems that the majority of the traditional QS role sits with the engineer. There is a small commercial team here who are responsible for approvals, contract negotiation/writing and payments. I’m interested to hear if this matches the experience of the other students on placement as it was not what I expected. So what?

– Advantage: site engineers are more aware of the cost of their works so in theory produce more efficient designs and reduce overall project costs. Reduced costs = increased profit.

– Disadvantages: the organisation is split into various sub-teams working on different parts of the project. With each team resourcing their own packages there are missed opportunities to benefit from economy of scale particularly when there is limited communication between the sub-teams. This results in the duplication of tendering when works across the project could have been combined into one works package. There is also a significant amount of ‘group think’ in the office when selecting companies for tender packages which may not result in best value for money.

3. Drawings. The drawings for the bridge segments are incredibly complex and if I’m honest really blow my mind. Even the pre-cast yard foundation slab and steel shed erection drawings contain more detail than I’m used to. I think Phase 1 needs to cover reading and interpreting engineering drawings in more detail as I’m well behind the standard expected for the role I’m performing on site. Having example drawings at the front of the classroom during project assessments was a good start but I think more time invested in this area would make the Phase 2 transition easier to manage.

4. Military experience. The military environment provides a range of transferable skills that are really useful in the construction industry. From managing people and meeting tight deadlines to technical issues like how to build a bailey bridge (no I’m not joking they are building a bailey/Maybe bridge here) we can add heaps of value. Regardless of what you’re doing two rules remain:

- No plan survives contact.

- Keep it simple stupid.

I’m glad you picked up on the slang too Mark! FRP got me in my first few days. And you’re not wrong about the planning, designing and resourcing, something that appears to take up a lot of time for the engineers on my project. This is something I raised after my first week, as I was surprised by how much if this was left to the engineers. Hopefully I’ll get up to see you at some point and have a look at what you’re doing!

p.s. Great weather!

Hi Mark, sounds like an interesting project and lots of opportunity to gain experience across a number of disciplines. Just a quick reply on your observations regarding the commercial responsibility of the engineers in Australia. I had exactly the same experience on the Melbourne Metro Project. For any of the work packages I ran, I was responsible for ensuring they had the manpower and resources to complete the task (everything from plant and machinery to the nuts and bolts). As you identified, this involves a number of short form contracts(minor/major works and services), variation orders (VO’s) or work package instructions (WPI’s), all of which I had to draft as the engineer and then forward to the commercial team for checking before they went out. There are templates, but it does take time. Great stuff for CPR – however, towards the end of phase 2, I did find it an inefficient use of and engineers time, especially when you are trying to deliver all of the other paperwork and supervision required when your work packages go into construction. If one exists, have a look through taskorg for your site/project, I would be surprised if there isn’t a spot for a resources manager and procurement clerk. We had the places, however, it is an easy way for the project to save costs by not filling these positions and offloading the work to Project/Site/Grad engineers and Cadets. Eventually, we had a new Senior Project Engineer (SPE) and Construction Manager start and they took on the fight to get the positions filled. In the end, I think it saves the project money as you don’t have 4 or 5 engineers ordering the same resources for their packages on an individual basis. Probably why the positions are on the taskorg in the first place………….

Hi Mark, I found on my project the whole 3 quotes business was a bit of a nightmare and not suited to delivering fast paced construction where issues need to be resolved very quickly as they arise. I found myself fighting the system a little to justify why I hadn’t obtained 3 quotes for something like fabricated shim plates where some of out propping was out of alignment and was holding up progress. Either that or expending lots of time and energy ringing round for quotes. (This eased off a bit when we had a storeman assigned to manage the material coming in, and I could just let him know what I was after and he would have the quotes turned around pretty quickly through his contacts)

The alternative would have been for the project to select preferred suppliers and set up contracts with fixed rates from the start. This would have made things a lot easier in the supply chain, especially for the likes of nuts and bolts which we ordered in vast quantities throughout the propping installation.

At the end of the day it comes down to the commercial approach on the project and in my case this was dictated by CPB who were in partnership with JH. They are very heavy on the commercial side of delivering construction and minimising spend (by all accounts more so than other contractors such as JH). Therefore there was a lot of scrutiny and long armed screw driver on spend by the engineering team, which could be a bit frustrating. (I remember the commercial manager was ill for a week and we couldn’t get any purchase orders singed off to get material in….)

Chaps, thanks for the replies. I’m glad to know I’m not the only one to have picked up on these differences.

As for the commercial side. Our project has a commercial team currently of 3.5 full time on the project with another position gapped. At the moment they seem to spend their time firefighting issues where the engineers have accepted quotes or contracts that don’t match national agreements. I’m sure it will become slightly less muddy with time.

Looks like the challenge of getting onto a good site worked out well in the end. I concur entirely with the above observations of efficiency and false efficiency, and also the utility of all of this at CPR. The learning curve is very steep at first but the line “I didn’t say it would be easy, I said it would be worth it” remains true.