Engineering surveying

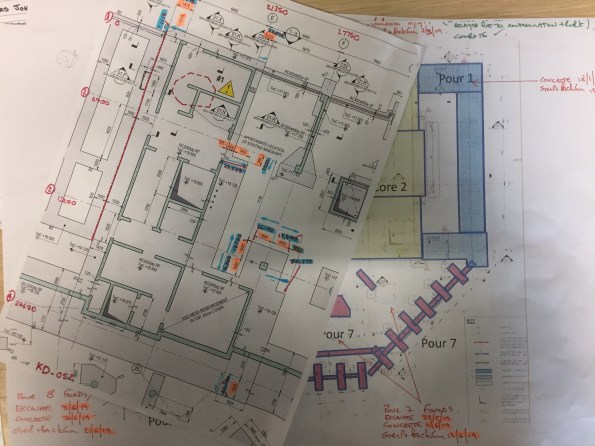

Introduction. I am now in week 3 with Multiplex on the University of Glasgow campus development, working on the £80m Research Hub project In general, the structure is a 6 storey reinforced concrete frame using flat slabs, piled foundations, steel frame roof level, pre cast concrete cladding and curtain walling. Piling finished in February with the rest of the substructure works in progress.

Issue. Along with the site engineer I have been looking at ways to improve the efficiency of our construction layout surveying. Particularly our methods used to control elevation, horizontal position and dimensions. At present we use a co-ordinate based setting out system with a Leica Total Station and are looking to improve our workflow prior to conducting as builts and setting out of MEP systems. At the moment 1 of 2 methods is typically used:

Method 1 – The junior site engineer is using a manual method. Using a dimensioned drawing, offsets from gridlines are calculated then checked on site using a reference line function.

Method 2 – The senior engineer has been replicating the project Revit model for the element, then exporting the lines to Autocad. From here the intersections are exported as a CSV and checked using the stake points function.

Neither method is ideal and so we have been looking at 2 alternatives.

Alternative 1 – Leica Building Link. This allows points to be added directly to the federated or structural Revit model. These can then be exported as an XML onto the Leica and re imported on completion to provide as builts.

+ Free, easy to use.

– Only compatible with Revit 2017, manual input method creates user error and is time consuming.

Alternative 2 – Autodesk point layout. Similar to Leica Building Link this can add points directly to the federated or structural Revit model. It has an automatic function and ability to create naming conventions.

+ Can quickly generate large numbers of points (possible to tie in with Revit families), compatible with Autocad and Navisworks, can create slab analysis heat maps.

– Relatively expensive, more complex to use compared to Leica system.

Further considerations:

Trust. Do we trust the federated /structural Revit model? It is seen as the point of truth but may contain errors. Therefore is it better for the contractor to produce their own model to identify buildability issues in advance? This can then be checked using clash detection.

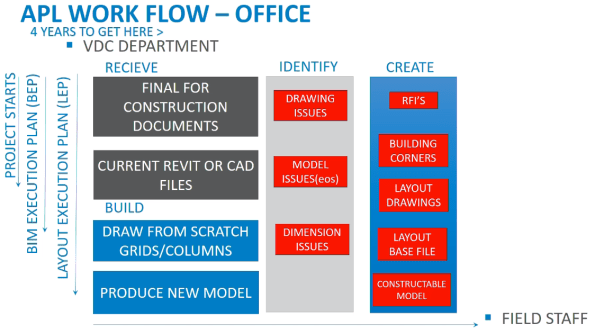

Best practice. This Autodesk seminar video outlines the use of a point layout approach by a contractor in the US (https://www.autodesk.com/autodesk-university/class/Best-Practices-Utilizing-Point-Layout-2017#video). They discuss the benefits of system but note that it has taken years for them to optimise the way they integrate it and to design a workflow process.

Summary. Our current methods of engineering surveying are inefficient with room for improvement. Does anyone have experience of similar issues or advice on successful methods used in the past?

Looks like you’ve timed your arrival with the project programme well – my Ph 2 looked similar when I started. Last bit of groundworks then start throwing up the structure?

Lot of challenging interfaces with all the different materials / tolerances / structural actions etc.

We used your Alt 1 – Leica Bldg Link.

Was great for Laing O’Rourke internal engineers but became difficult when passing information to SC engineers who were only on site for a day at a time and had no access to a federated model. Our model quickly became the most current source of the truth and the lag to issue of changes in construction information created a disconnect between setting out / checking by principal contractor and subbies.

Get as many retros up as you can and add them to a control register.

Cheers Joe, yes we are at the stage that you describe. It is difficult to ensure that any last minute design changes are incorporated in the build and not sitting in the document management workflow.

We are looking to run with Leica Building Link and tried it out yesterday. It seemed effective and we have also spotted the opportunity to use the Leica Inspect Surface app to check surface deviations.

We are on a TS16 which does not have the laser scan function so we are looking at getting a MS60 (cost permitting) to make things a bit easier.

I have copied this off to Margaret Beach so she can laugh loudly about it and more seriously so that she can see what it is you face after leaving her capable hands. I will post and response she might send.