Bridge over troubling roofs (Part 1)

Hello all, the Pier 6 extension at Gatwick is still going through the RIBA 3 design stage so I thought I’d switch fire to another project in the pipeline. The International Departure Lounge (IDL) link bridge is due to be built at Gatwick in the third quarter this year. It is still in the RIBA 4 design stage with the awarded works contractors now looking at the detailed design. The purpose of the bridge is to provide a more direct route between the new code F site at Pier 5 (see my first blog post) and the departure lounge. In short it is intended to improve passenger flow to the new A380 aircraft stand. At the moment passengers have to walk an indirect route to access the Pier 5 stands which adds additional walking time, reducing flow.

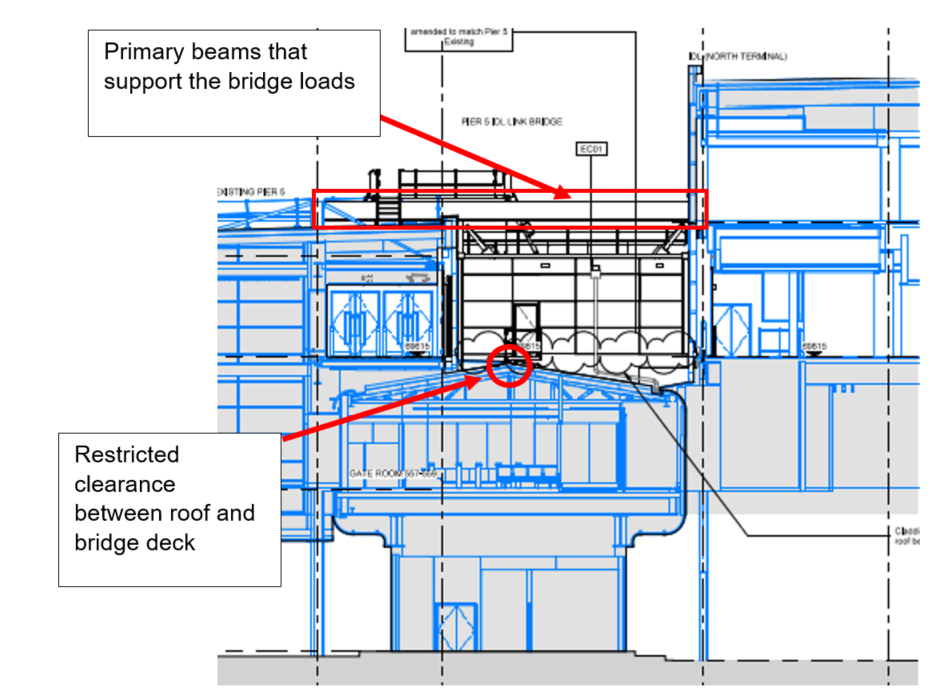

The construction of the bridge presents some interesting challenges as it is to be located in a heavily built up part of the airport. As can be seen in Figure 1 below, the location of the bridge is difficult to access for plant and equipment. Crane access is also difficult due to the size of the existing buildings, limiting prefabrication options. Therefore the building is to be stick built to account for the congested site.

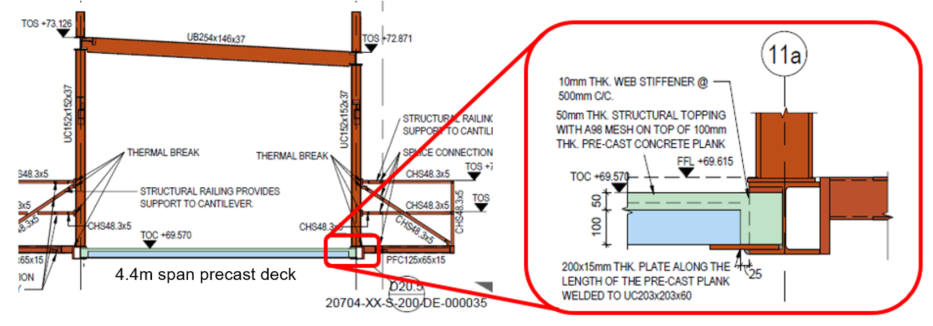

The proposed design can be seen in Figure 2 below. Due to the level of the bridge deck and the roof structure of the building underneath, the clearance of the top of decking and the top of the roof ridge is approx. 200mm. This has dictated the size of the beams that support the deck as can be seen in Figure 3 further on. This means that a traditional bridge structure where the deck beams are supported below is not feasible. The design therefore transfers the bridge loads from the deck through columns attached to two beams located above the bridge corridor. These connect to beams that span between the columns of the existing buildings.

These beams have to carry not only passengers, but also electrical passenger vehicles (up to 5kN/m2). A 100mm concrete precast decking solution using Bison beams with a 50mm screed reinforced with mesh has been specified by the designer (see Figure 3 below – Bison beams specified in notes).

Here come the problems: According to the contractor, Bison are no longer able to provide the 100mm decking solution and this issue has gone back to the designer. A composite deck with steel profiling is not possible due to deflection limitations set out in the specification (limited to span/360). The designer claims that there are no suppliers who are willing to provide a solution and a redesign is required. However, having had a quick search of suppliers myself, there do seem to be some out there who can meet the spec – maybe the designers haven’t looked hard enough? I’ve not had chance yet to enquire with the designer about this.

From the client point of view there is a reluctance to change the design to accommodate a deeper decking. The first is that by increasing the thickness of the precast concrete decking slabs, the screed would be thinner; risking cracking issues if there are deflections. I would think that this may not be an issue as the precast decking would have pre-tensioned reinforcement? However, the spec (from Gatwick) states that crack widths are limited to 0.1mm and although this seems rather excessive, maybe this is a legitimate concern.

The second reason is that in changing the design thickness of 100mm, the designer would have a reason to add delays to the design of the bridge (which is already delayed and not yet finalised). As they are on a cost reimbursable contract (the reasons for this in itself are enough for a separate discussion!) any major design changes will incur a heavy cost. I think this may be why the designer hasn’t really investigated all 100mm decking options as there is no incentive for them to do so under this kind of contract. Instead I suspect they want to use this as a reason for delay to the design schedule by significantly changing the deck design.

As a side note there are also challenges around the temporary works and scaffolding required to enable the project. However, I think this deserves its own blog post so I’ll leave you on the edge of your seats for my next exciting instalment.

Clearly using high level beams and hangars makes sense. That the deck then does 4.4m clear between supporting beams with only 100mm structural depth is a challenge. I suspect you’ll end up with 150mm, a 0-5mm latex screed and finishes directly applied. This probably won’t deliver the thermal performance you need!

Bison have been bought out by Forterra so are now part of a brick and paving products manufacturer. Bison provide Forterra’s toe in the specialist technical structural components market. They have had their range ‘reviewed’ and made competitive i.e. reduced and focused on volume sales with profits front and centre. You’ll get a 150mm hollow core plank. solid composite has gone.

You might, however be wondering where your steel will come from given the news that British Steel and 25k associated and related jobs along with it. The only UK structural sections will now be tube products so you’ll be queuing up for Indian or Chinese steel.