Archive

Gatwick concrete cracks

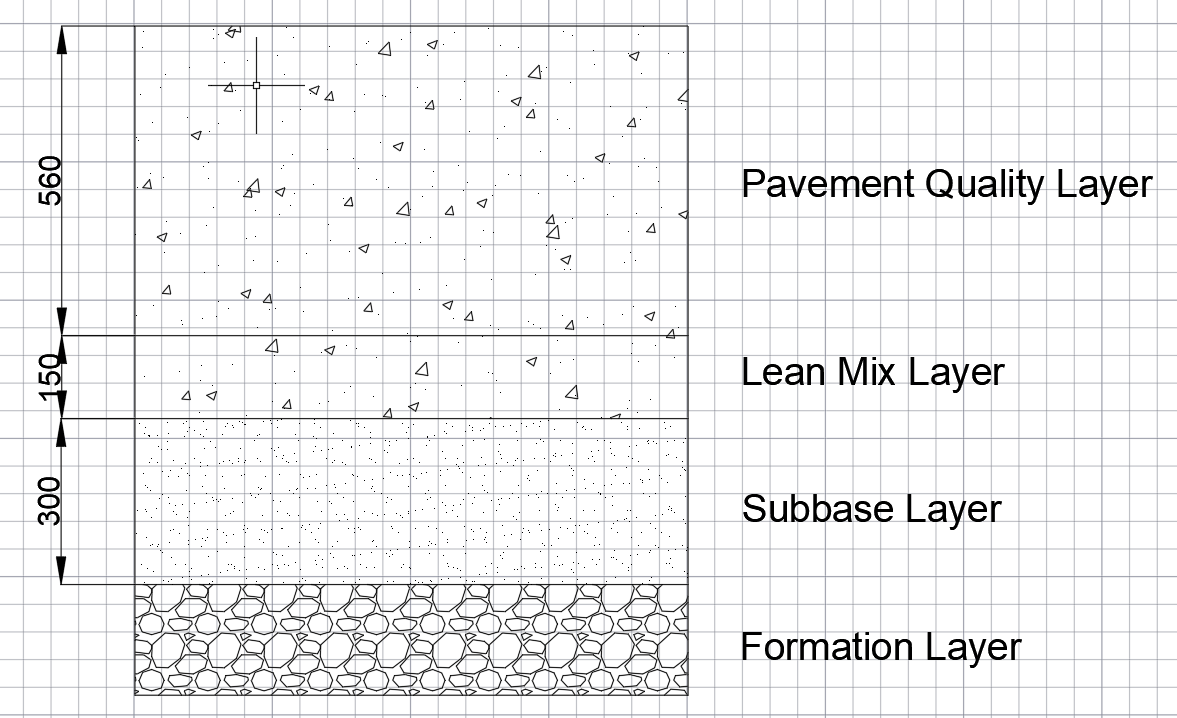

As part of the A380 stand upgrade works ongoing, the aircraft taxiway pavement is being upgraded to support the heavier loads of the A380. The pavement is of a ‘rigid’ design and has been constructed in three layers (see Figure 1): a granular subbase (300mm) with Lean mix concrete layer (150mm) with a specific Pavement Quality (PQ) mix layer (560mm). There is no reinforcement to the pavement quality layer as I understand it is assumed the concrete will be working in compression only. The concrete for the new stand is being built in sections, with one of the longest sections cast recently. This section was cast 30m in length total by 5.5m widths and then cut into 6 parts for movement joints.

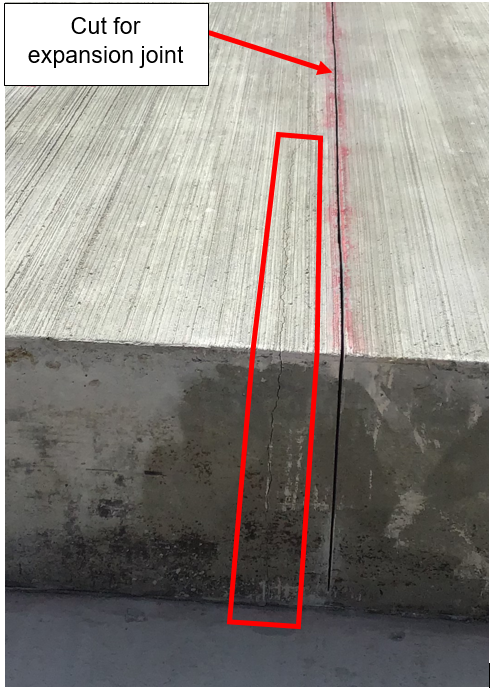

It was discovered recently that a substantial crack had developed through the thickness of the PQ layer at this section. The crack is highlighted in Figure 2 below.

It is thought on site that the crack sits over a hard area of ground and may have formed a crack where the concrete was acting in tension. As the crack is close to the cut for the expansion joint it may be possible that the contractor waited too long before cutting the joint, resulting in the crack.

It is likely that this PQ layer will have to be broken out and cast again, as water ingress into this crack will cause future problems. The crack may have been avoided by casting the blocks in smaller sections, reducing the tension on the PQ. I would be interested to know any thoughts on this problem and any ways in which it might be resolved. Such an issue will no doubt be costly for the ground works subcontractor.