Gatwick concrete cracks

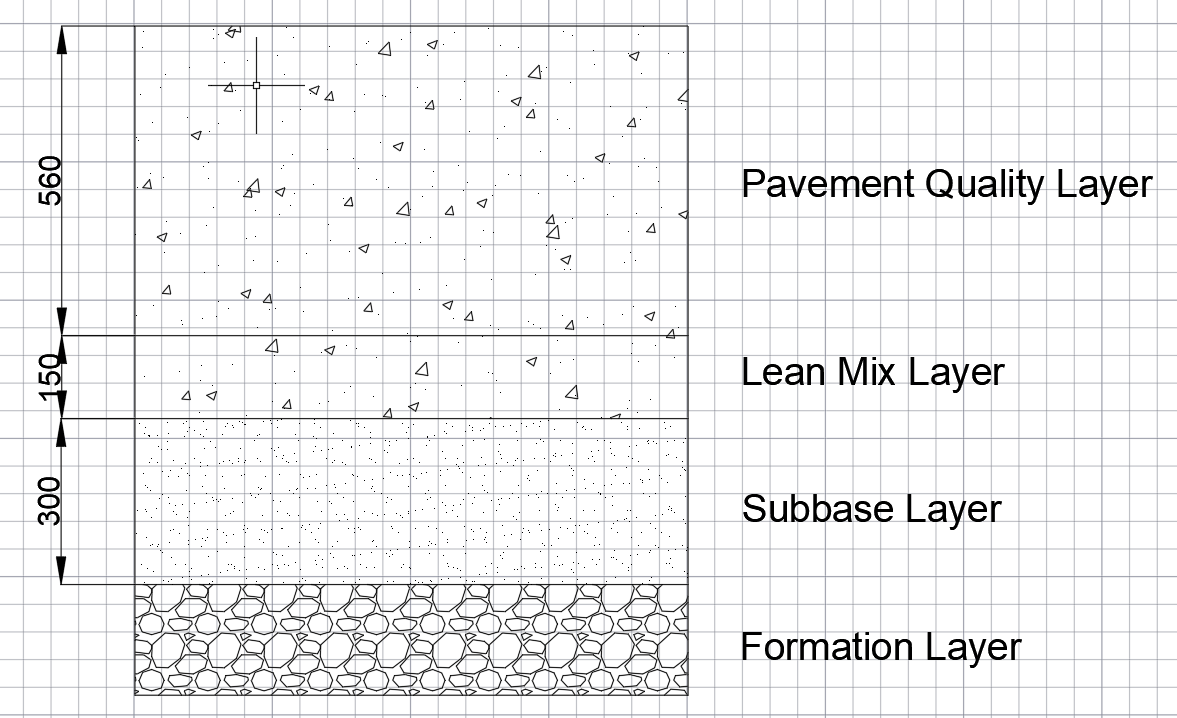

As part of the A380 stand upgrade works ongoing, the aircraft taxiway pavement is being upgraded to support the heavier loads of the A380. The pavement is of a ‘rigid’ design and has been constructed in three layers (see Figure 1): a granular subbase (300mm) with Lean mix concrete layer (150mm) with a specific Pavement Quality (PQ) mix layer (560mm). There is no reinforcement to the pavement quality layer as I understand it is assumed the concrete will be working in compression only. The concrete for the new stand is being built in sections, with one of the longest sections cast recently. This section was cast 30m in length total by 5.5m widths and then cut into 6 parts for movement joints.

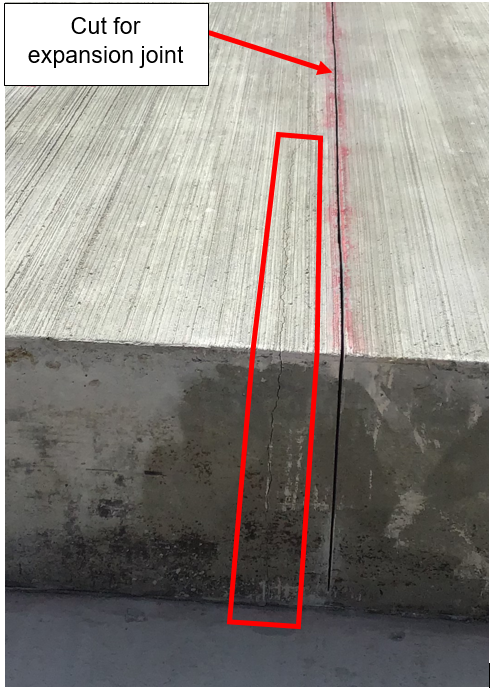

It was discovered recently that a substantial crack had developed through the thickness of the PQ layer at this section. The crack is highlighted in Figure 2 below.

It is thought on site that the crack sits over a hard area of ground and may have formed a crack where the concrete was acting in tension. As the crack is close to the cut for the expansion joint it may be possible that the contractor waited too long before cutting the joint, resulting in the crack.

It is likely that this PQ layer will have to be broken out and cast again, as water ingress into this crack will cause future problems. The crack may have been avoided by casting the blocks in smaller sections, reducing the tension on the PQ. I would be interested to know any thoughts on this problem and any ways in which it might be resolved. Such an issue will no doubt be costly for the ground works subcontractor.

Al, who are the subcontractors conducting the work? Is it Tag by any chance? We are currently trying to get them into contract for our in situ topping.

No, Oliver Connell & Sons. They’ve not been too bad and the other concrete casting had been going well until this point.

It’s not an induced crack over a hard spot because it has a consistenc width from top to bottom not wider at top and narrowing towards the base. It looks absolutely like the second case cited i.e. it’s a shrinkage crack rising form waiting too long before saw cutting. THey should have been able to see it when they went to saw cut because the stress relief provided by the sw cut will have stopped it opening up more afterwards. This being the case they should have got on and adjusted the saw cut location to coincide ith the crack. options now are light weight lioquid resin into the crack to seal it, saw cut the crack to provide anoher contraction joint adjacent to the one shown or saw cut and break out a section and replace. .

A few things:

As to your note:

‘There is no reinforcement to the pavement quality layer as I understand it is assumed the concrete will be working in compression only.’

This is incorrect. Rigid pavements re designed to using Westergaard analysis methods, which are based on Bossinesq theory. All fancy names but in means that there is flexural stress sin a laded slab; concrete has a tensile strength which may be sufficient to overcome this – and that strength is used in the design of unreinforced concrete pavements.

TO the issue that you show. There is loads of guidance on the different joints used in pavement design. IN URC slabs the spacing of joint is normally taken and 4-4 times the raidus of relative stiffness ( see Westergaaard analysis). This tends to equate to about 25 to 30 times the slab thickness.

In air pavement you often try to use limestone aggregate because is arrests shrinkage cracking and theses spacings can be increased.

In pretty well any engineering you don’t wait for cracks to happen- or wait to put joints in and hope shrinkage cracks didn’t get there first. You put a bead in where you are later to execute a cut so that the bead induces any cracking where you already intend to cut.

John, in response to your comment, as you know we are about to put in a 0.15m reinforced concrete topping slab to act as a pavement runway. Currently there are no saw cuts planned within the concrete, which personally, having looked at this I think is a mistake, as we are placing virtually the same length. We have submitted an RFI to the designer questioning this but are awaiting a response.

Can you point me in the right direction for guidance what length between saw cuts would be most appropriate?