It always comes out in the wash…

Introduction

Gareth – it sounds like we could have done with the approach you describe in your blog post about 4 weeks ago… A little more attention to detail and closer supervision might have been of benefit!

The past few days have seen unsettled weather across eastern Australia. There has been snow in the mountains and even in the sunshine state (Queensland) to the north. The area I am in has survived largely unscathed however we have had high winds (gusting up to 130 kph stopping crane operations) and over 70mm of rainfall in one night (for perspective, site drainage is sized against a 37mm event).

Today was due to be the completion and opening of a new public temporary boat ramp which would allow us to close the existing boat ramp and start piling works on the temporary jetty. The jetty is required to transfer precast bridge elements from the shore onto barges in the river. At least that was the plan until 0705 this morning…

Background

Due to a number of delays, the senior site management has decided to conduct concurrent works to save costs and recover the programme. This has required a number of activities to be brought forward onto the critical path. To gain momentum on these activities some engineering ‘best guess’ has been applied in order to complete designs and gain environmental approvals. The temporary boat ramp is one example of this and there has been a big push to construct the temporary boat ramp as quickly as possible.

John Holland initially struggled to attract enough experienced site and project engineers so have backfilled with a number of engineers from their graduate programme. Sadly due to the lack of experienced engineers in the office and concurrent works, a lot is being asked of the junior engineers who are getting limited supervision from the experienced engineers.

To meet the required boat ramp construction timeline the decision was made to use the concreting contractor working at the precast yard. For two months they have been producing pre-cast boat ramp planks alongside the in-situ concrete foundation at the precast yard. The past two weeks have seen the workers move across to the boat ramp site to complete the in-situ concrete pours and install the pre-cast planks. The construction of the boat ramp has been nothing but challenging and from the sidelines, it has seemed like everything was ‘going off half-cocked’ resulting in poor quality finishes produced by the subcontractor (but that’s another issue). All the time this has rested on the shoulders of one of the graduate engineers.

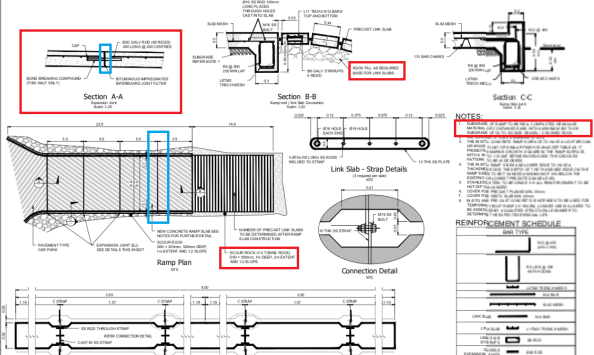

Temp Boat Ramp Drawing. Red boxes highlight the expansion joint detail and subgrade and rock armor notes. Blue boxes highlight the expansion joint.

So what happened?

This morning at the pre-start meeting (workers-management meeting) everyone was asked to check their areas for any issues. Shortly after the workers set off for the boat ramp the telephone calls started…

What follows are a series of photographs I took this afternoon at low-tide:

View from the existing bridge. The yellow and white floating items are silt and hydrocarbon booms which are part of the site environmental controls.

Side view from the bridge side. Note the rock armour on the left of the picture.

View standing on the ramp. Note the raised slab and seaweed position.

View back towards the bridge along the expansion joint. Note the curved dowels.

View along the expansion joint facing away from the bridge. Note the tilt and shift in the slab on the right of the picture.

Close up of lifted slab showing dowel sleeves and bent dowels. You can also see elements of subgrade stuck to the bottom concrete layer.

View between the slabs at the expansion joint. No subgrade is visible.

Side view facing back towards the bridge. The edge of the slab is 650mm thick so the slab has dropped at least 650mm at this side.

Focusing on the surrounding material. Note the geofabric, washed out material and missing rock armour. Apparently the workers tested the depth here with a 6′ scaffold pole which disappeared below the water surface at high-tide.

Analysis

It seems a number of errors and unfortunate circumstances have combined (swiss-cheese effect) causing a GEO failure. This resulted in structural failure of the expansion joint and serviceability requirements.

Today I was told the project looked at a number of locations to build the temporary boat ramp. The site near the bridge was chosen for speed and convenience despite recommendations not to build there. The sandbanks there are described as ‘highly-mobile sands’ and locals have known them to move frequently move position 10 – 15m. The site is also close to the existing bridge piers as you can see from the photographs. The combination of the piers in the river channel and construction of the boat ramp out into the river will have changed the river flow and velocity at the boat ramp location. This is likely to have increased the localised scour effects.

Typically the mean high tide level is 1.4m above the Australian Height Datum (AHD). Last night there was a high tide surge to 1.9m AHD (remember the seaweed in the photograph above) with water above the expansion joint. The effect of the surge (linked to the recent bad weather) was to undermine the boat ramp slab and scour away the foundations. Greater scour was experienced on one side of the ramp (seaward side) resulting in the slab tilt and shifting. The damage to the expansion joint was caused by the self-weight of the slab.

The drawings show a minimum 200mm subgrade of 50 – 150mm gravel or crushed rock. They also show the scour rock armour was to be 500mm deep and extend 1000mm from the ramp up to the end of the in situ concrete works. The rock armour was to continue around the precast planks in a larger size rock, 1000mm deep and 2000mm out from the precast planks. The rock armour was incomplete (due to be finished this morning) but already questions are being asked about the design and if it had been constructed correctly.

The bad news (from John Holland’s perspective) is that damage to works from tidal events are not insured (are John Holland’s risk) and the site is in the center of town so is bad PR. The good news is that no-one was hurt and the ramp had not been opened for public use.

Conclusion

It is still too early to determine exactly where the fault lies and if closer supervision of the junior engineers would have given a different result. The question is now is what’s ‘Plan G’? Was it an out-of-design event? Should we reinstate or rebuild elsewhere? DO we need to change the design to include sheet pile scour protection? I’m sure it will all come out in the wash (pun intended).

The impact will be significant reworks to remove and reinstate/construct (additional cost). There will also be delays to other project work packages as the existing public boat ramp cannot be closed. This will cause delay and disruption to the piling sub-contractor who will soon start to accrue daily standby charges. The figures make the eyes water! So a quick resolution is in everyone’s interest.

Three aspects of interest: What happened, why and how; Who is going to be found to be at fault, to what extent and with what repercussions legally and contractually; How are you going to move forward from here practically and in terms of reputation (we can’t build a small boat ramp but trust us the bridge will be OK?!). I think you have identified this much already and it has just written your next TMR proposal for you.

Your last image has a caption noting workers tested the depth of the scour hole and therefore absent support to a slab using a scaffold pole at high tide. I’d love to learn more about the risk assessment for them presumably standing on a structure known to not be performing within SLS and undergoing a ULS failure with unknown extent of support. Tell me they didn’t think that because it was concrete that they could just walk out on the unsupported cantilevering slab with flowing water moving through an evidently undermined foundation of unknown extent and just put a pole in the water? If so where’s the near miss and H&S follow up for that one!